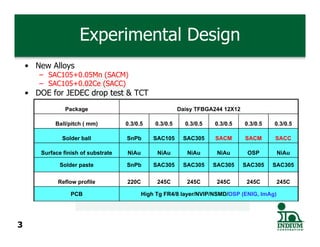

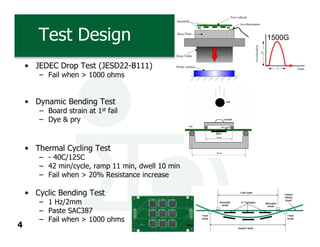

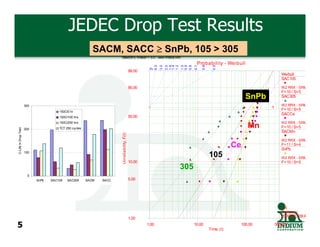

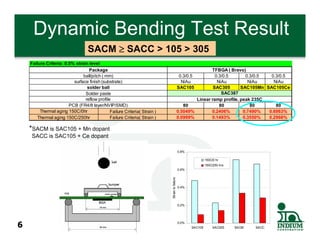

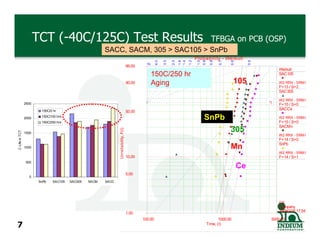

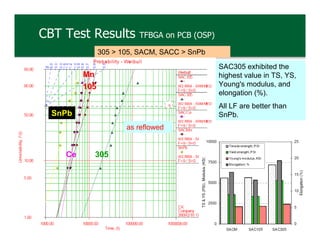

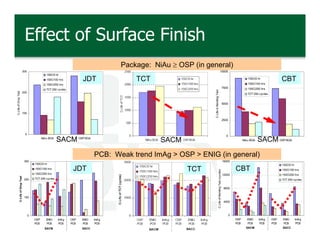

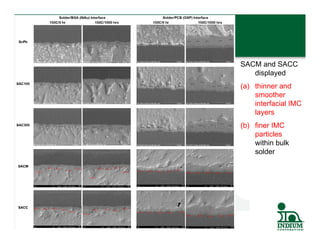

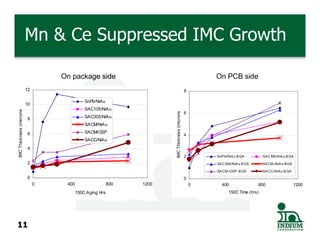

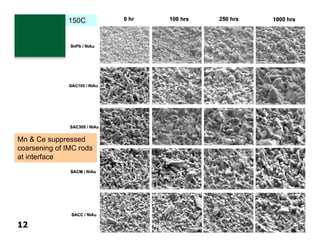

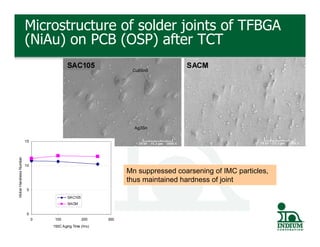

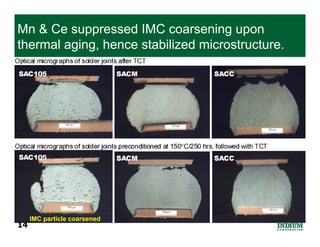

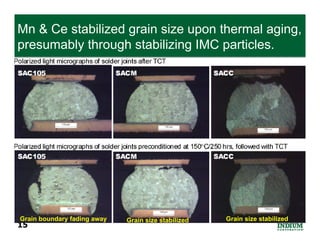

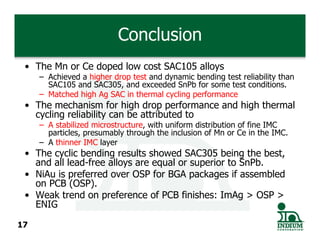

This document summarizes research on achieving high reliability and low-cost lead-free solder joints using manganese or cerium doping of tin-silver-copper (SAC) solder. Experimental results show that SAC doped with 0.05% manganese (SACM) or 0.02% cerium (SACC) outperforms baseline SAC105 and SAC305 alloys in drop test reliability and thermal cycling performance. Specifically, SACM and SACC exhibit higher drop test lifetimes and allow packages to withstand higher dynamic bending strains compared to SAC105 and SAC305. This research demonstrates that minor manganese or cerium doping of SAC alloys can improve