The document discusses Fine Tubes' production of medical-grade stainless steel and titanium alloy tubing. It provides details on:

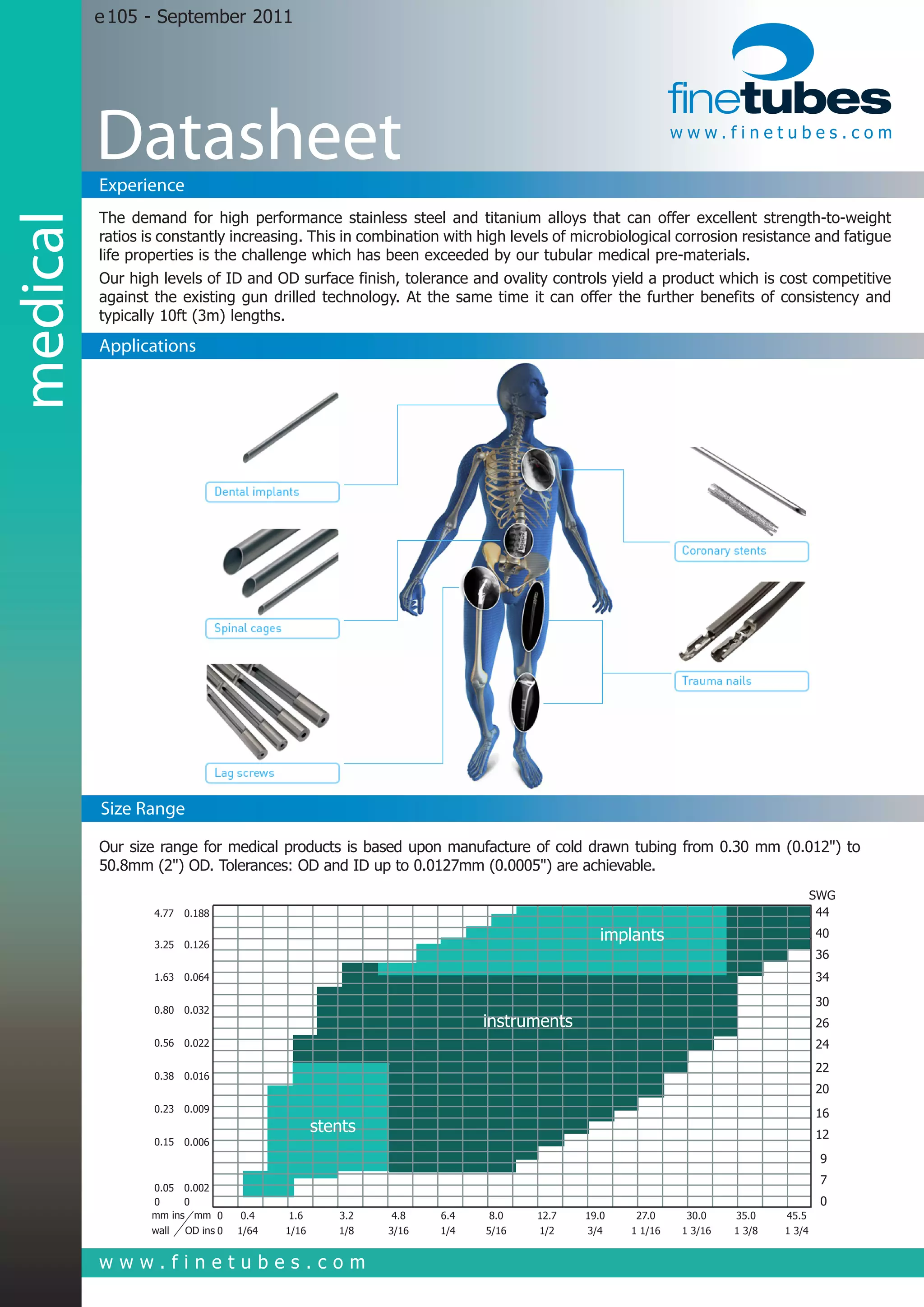

1) Their size range of 0.3mm to 50.8mm outer diameter tubing that can achieve tolerances of 0.0127mm.

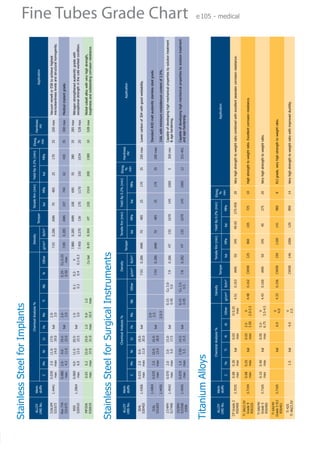

2) Their quality control process which controls parameters like surface finish, inclusion levels, and grain size to stringent levels.

3) The advantages of their tubing including refined inner surface finish, low defect levels, and tight tolerances.