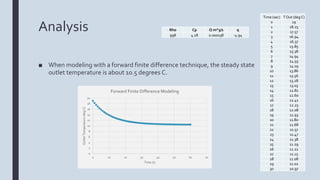

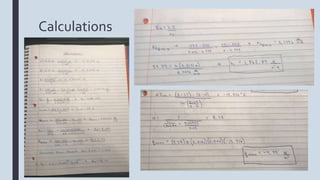

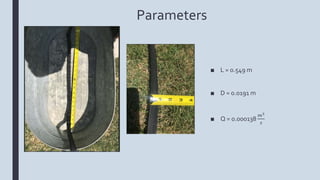

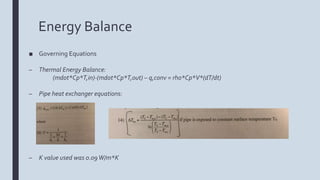

The document describes an experiment to model a pipe heat exchanger that cools water as it passes through a tub of ice. The student measured the inlet and outlet temperatures of water running through a garden hose submerged in an ice bath. The outlet temperature reached a steady state of 17 degrees Celsius within 4 seconds. Modeling with finite differences predicted a steady state of 10.5 degrees Celsius, showing a difference from the experimental results. Decreasing the mass flow rate through the pipe could achieve lower outlet temperatures by allowing more time for heat transfer. Suggestions for improving the experiment included not pre-cooling the hose and using software to better model heat transfer.

![Results

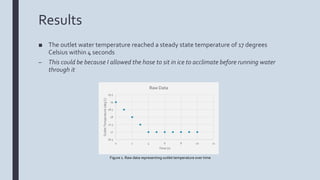

■ Holding all other things constant, mass flow rate can be decreased to achieve different

desired outlet temperatures

0.000

0.050

0.100

0.150

0.200

0.250

0 5 10 15 20

MassFlowRate[kg/s]

Outlet Temperature (deg C)

Required Mass Flow Rates to Reach

DesiredTemperatures

InletTemperature (deg C) Desired OutletTemperature (deg C) Mass Flow Rate Required (kg/s)

19 18 0.235

19 17 0.117

19 16 0.078

19 15 0.059

19 14 0.047

19 13 0.039

19 12 0.034

19 11 0.029

19 10 0.026

19 9 0.023

19 8 0.021

19 7 0.020

19 6 0.018

19 5 0.017

19 4 0.016

Figure 2. Mass Flow Rate vs.Temperature

Table 1. Mass flow rates required for desired outlet temperatures](https://image.slidesharecdn.com/be4120presentation-201112214202/85/Be-4120-presentation-9-320.jpg)