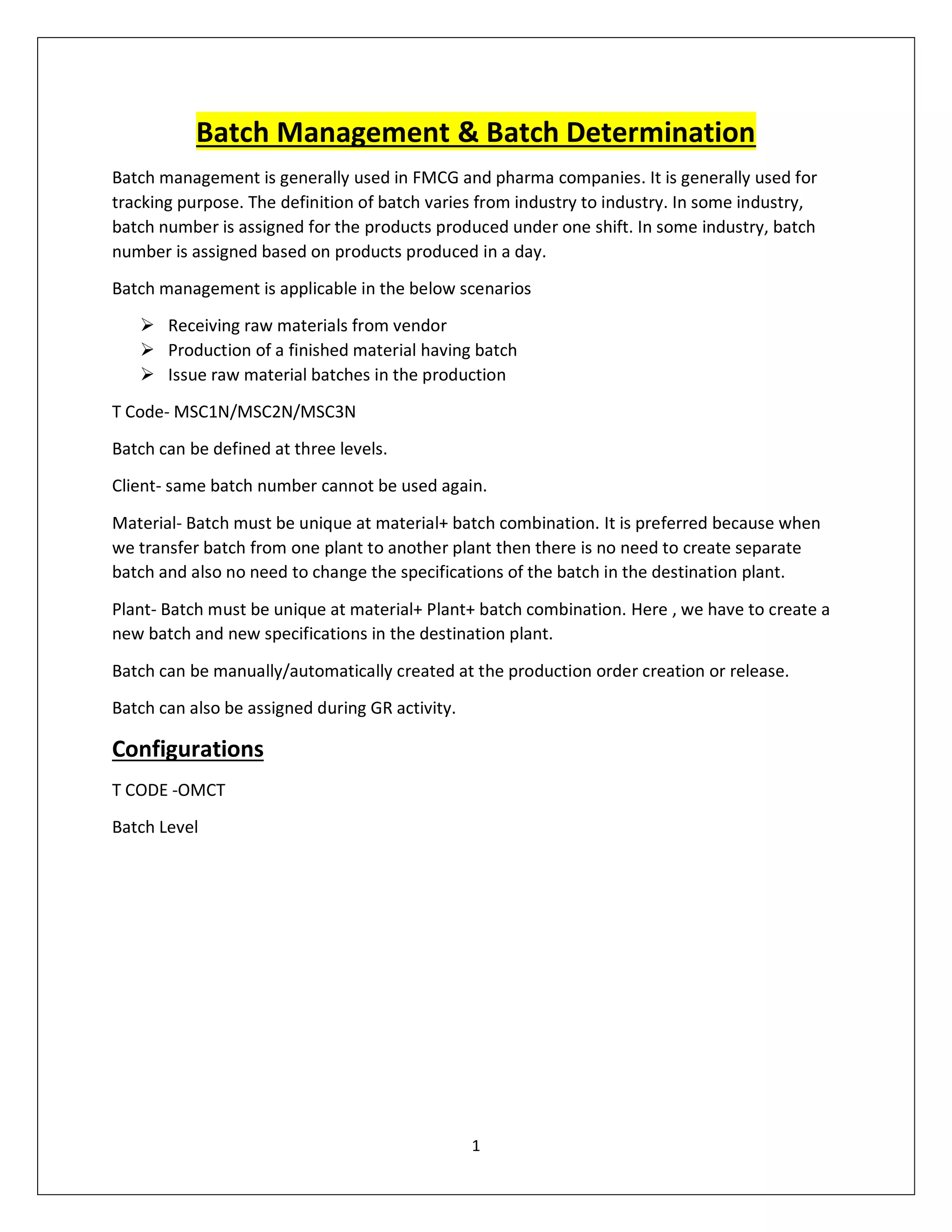

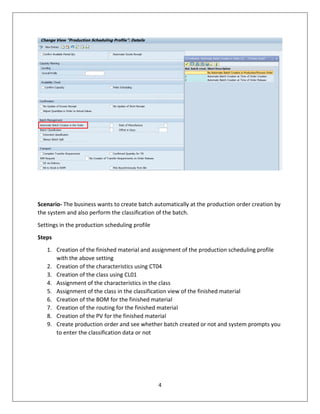

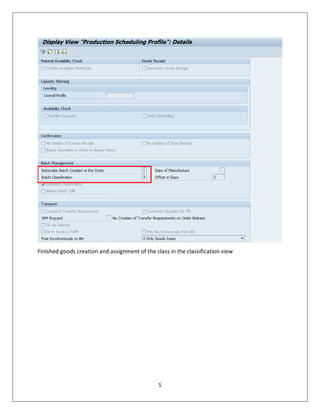

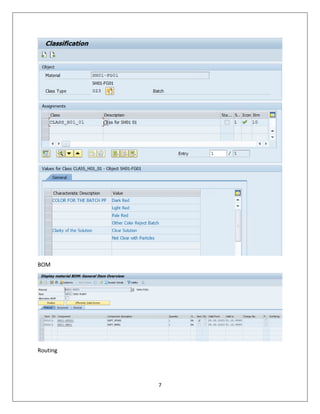

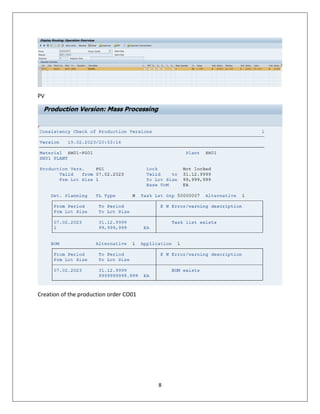

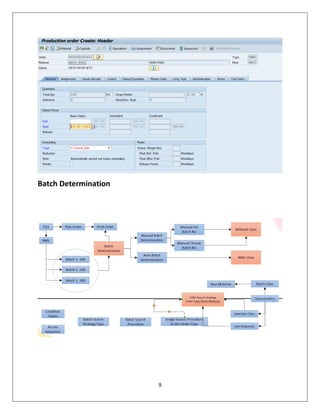

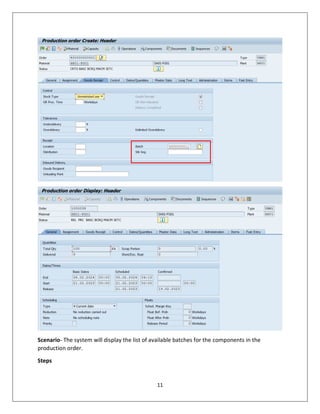

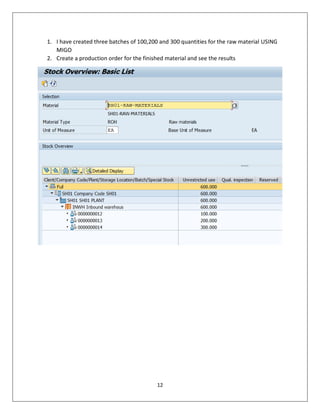

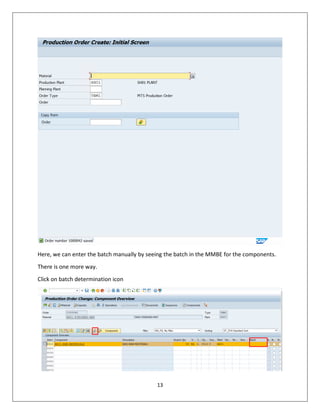

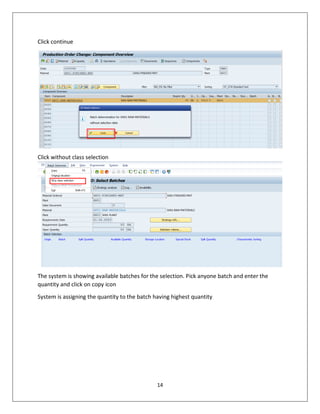

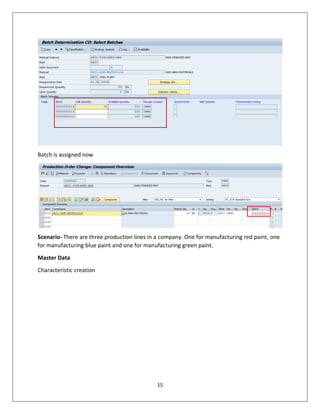

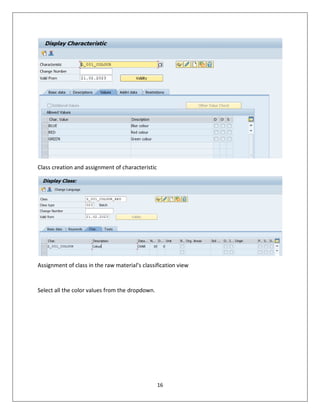

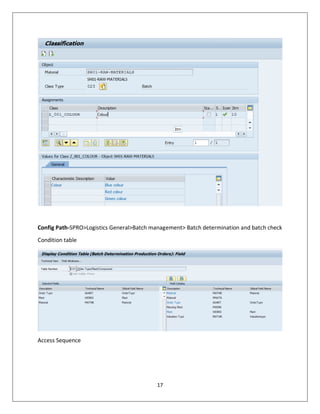

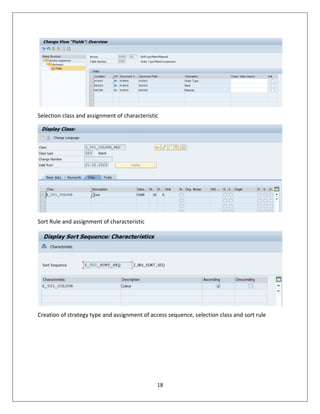

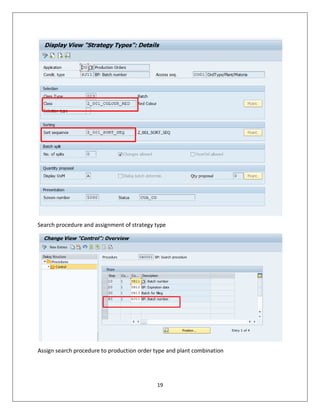

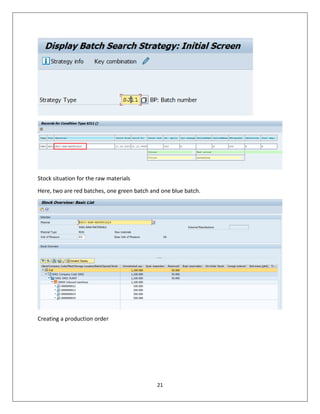

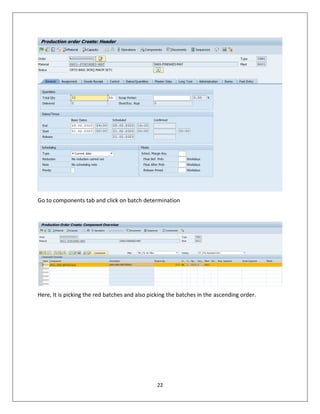

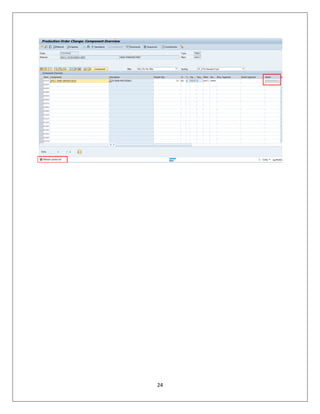

Batch management is used in industries like FMCG and pharma to track products produced in shifts or days using unique batch numbers. Batch can be defined at the material, plant, or client level. Batch numbers can be manually or automatically assigned during production order creation or goods receipt. The document provides steps to configure automatic batch creation and classification in SAP during production order creation and release. It also describes how to set up batch determination to display available batches for selection or automatic assignment based on characteristics, classes, strategies, and stock levels.