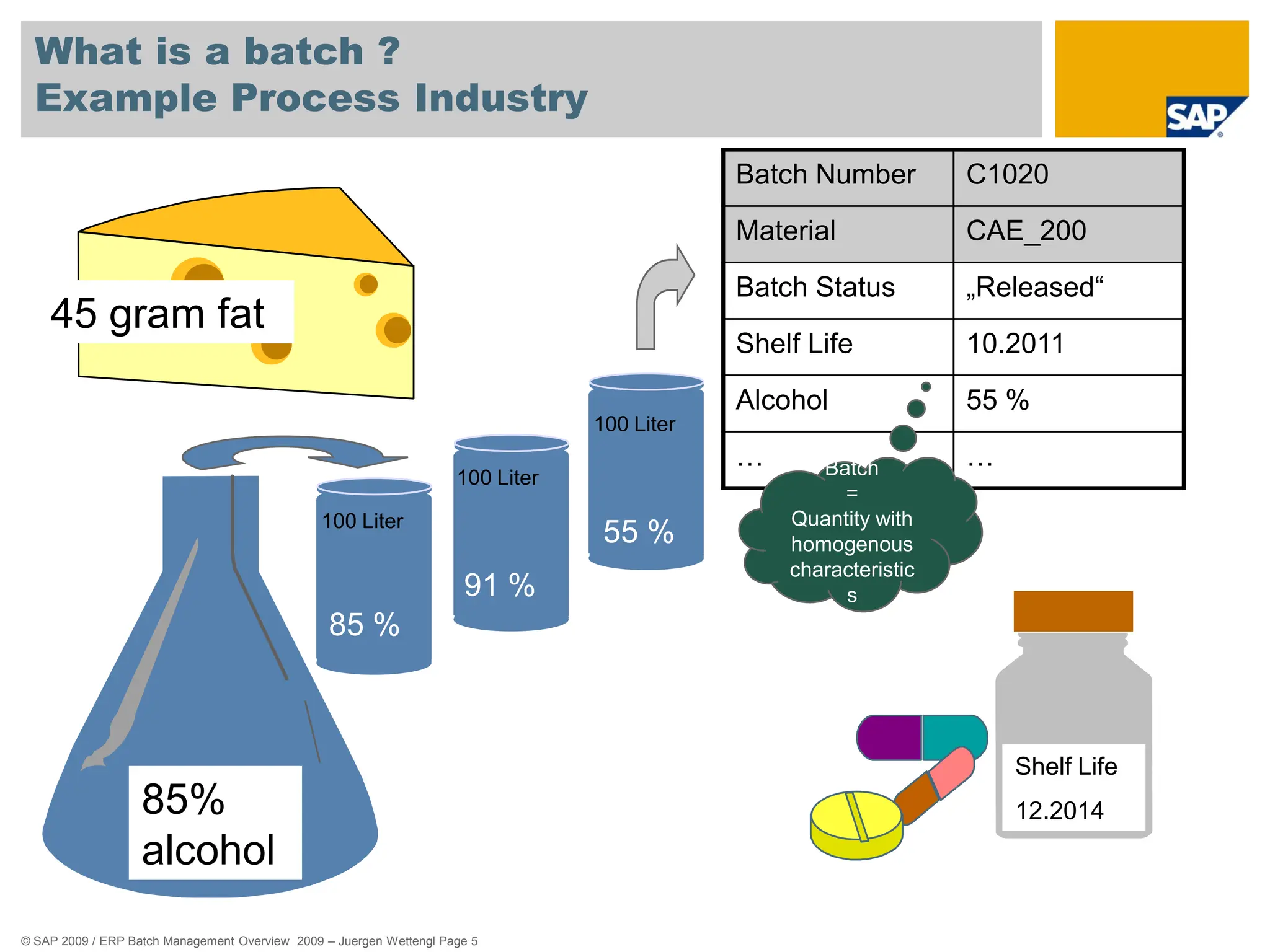

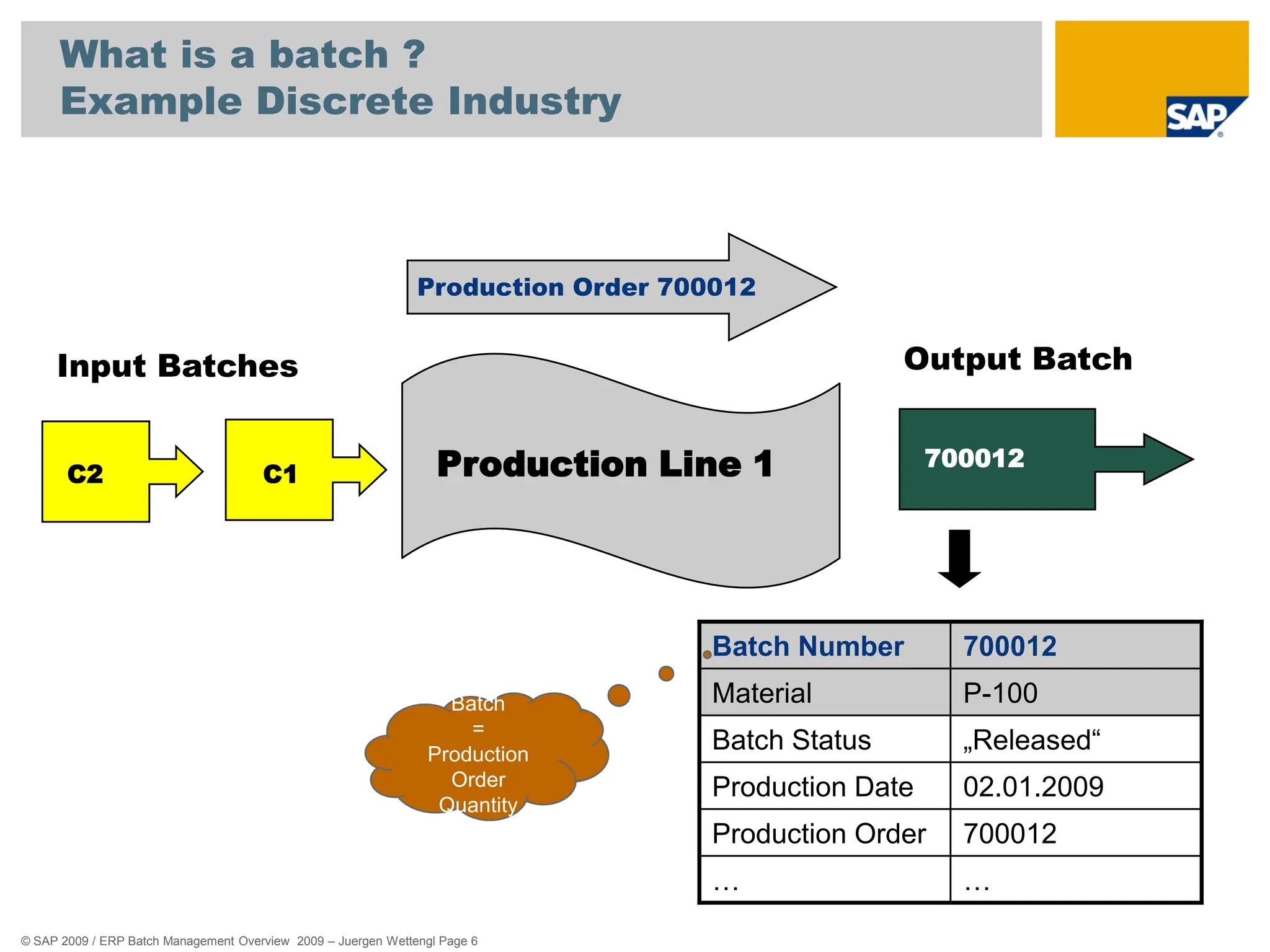

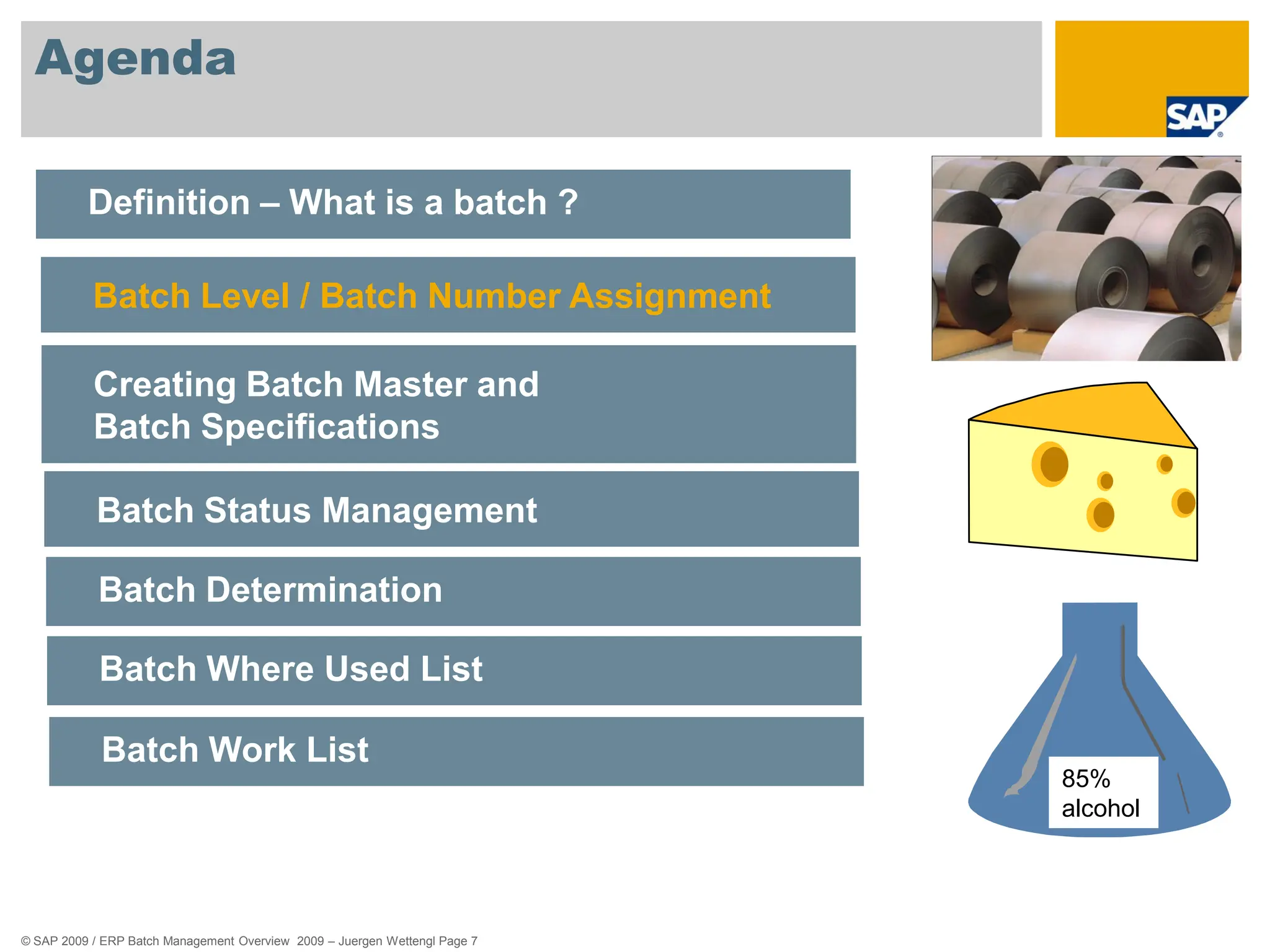

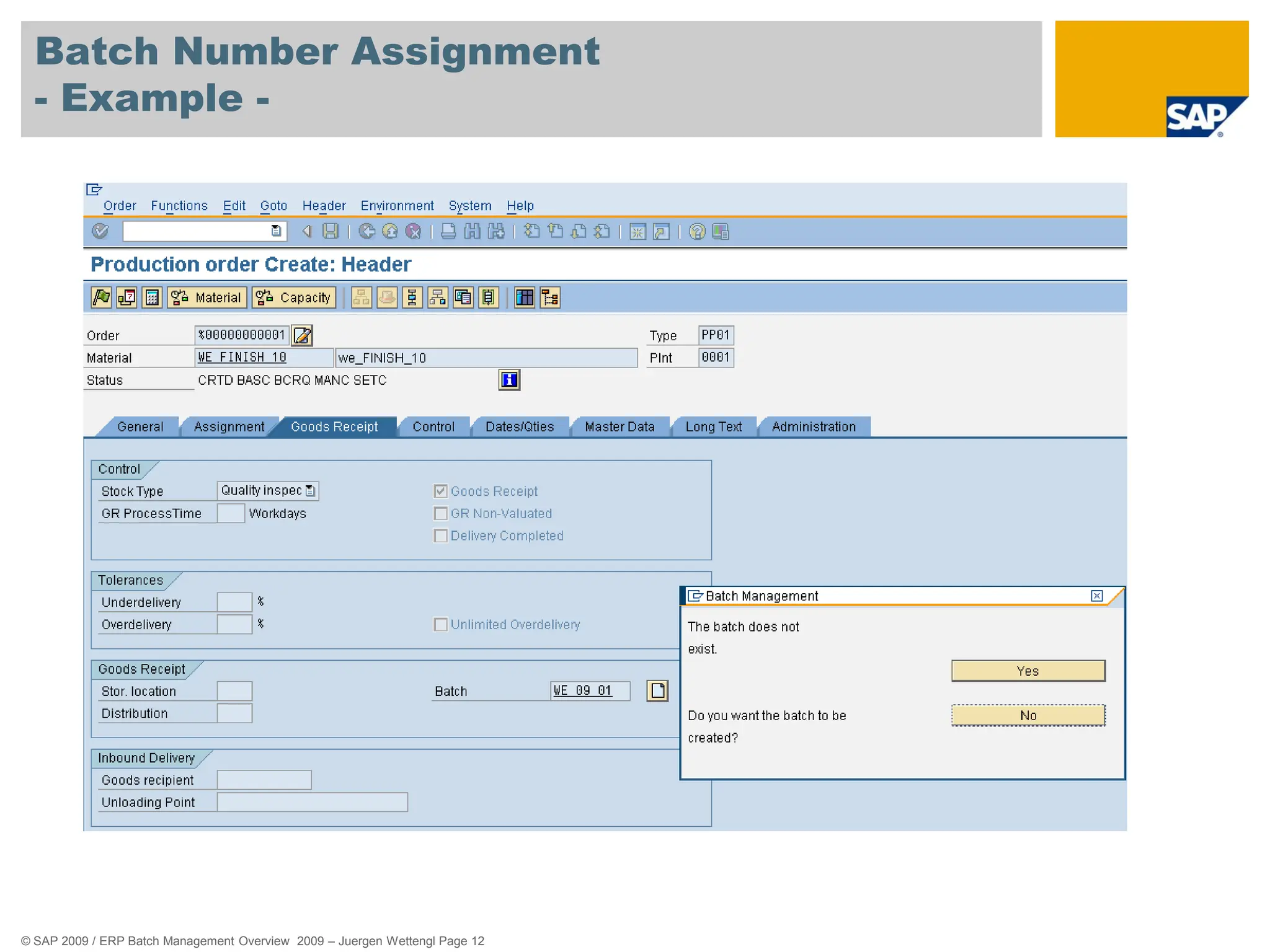

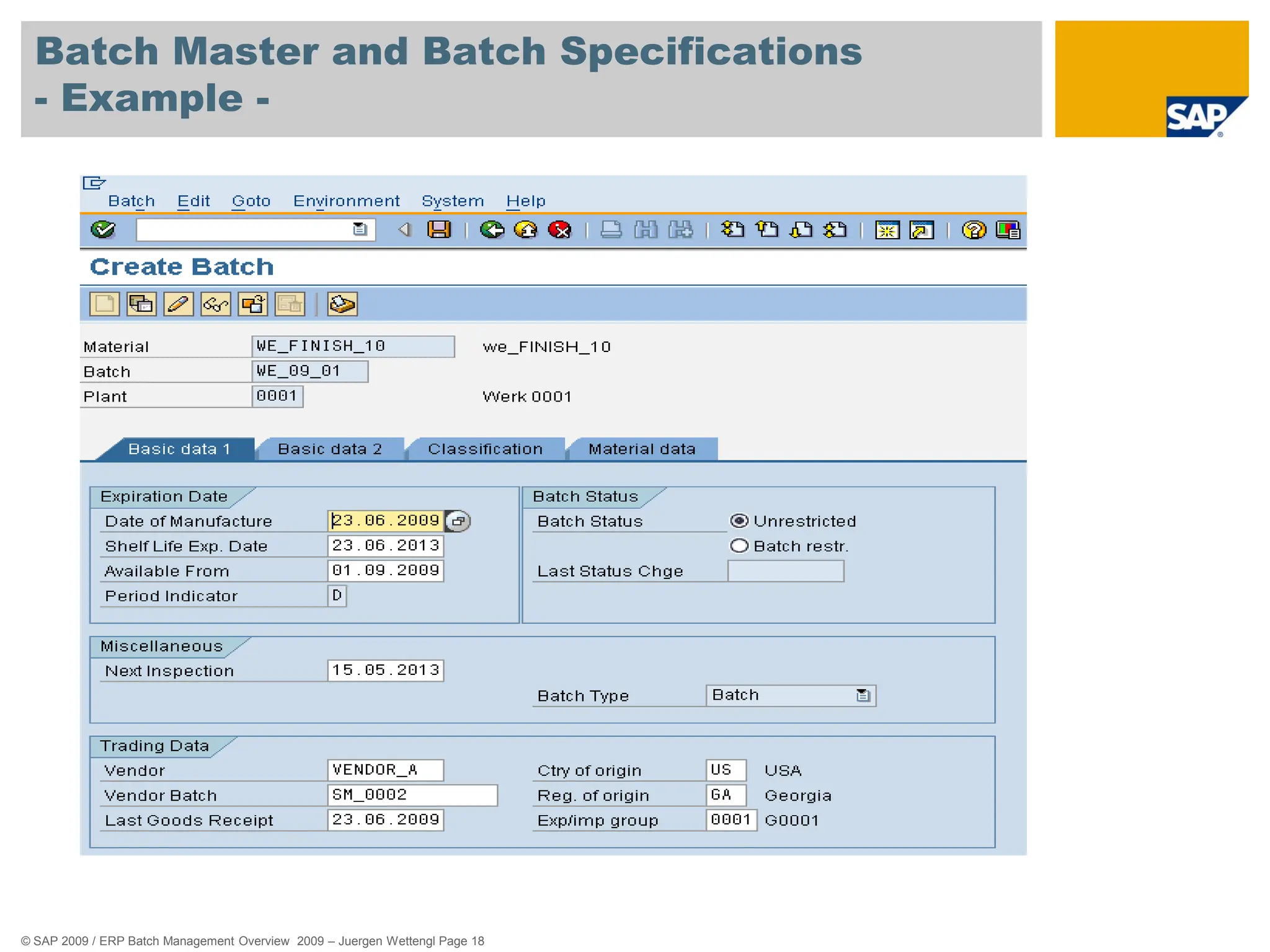

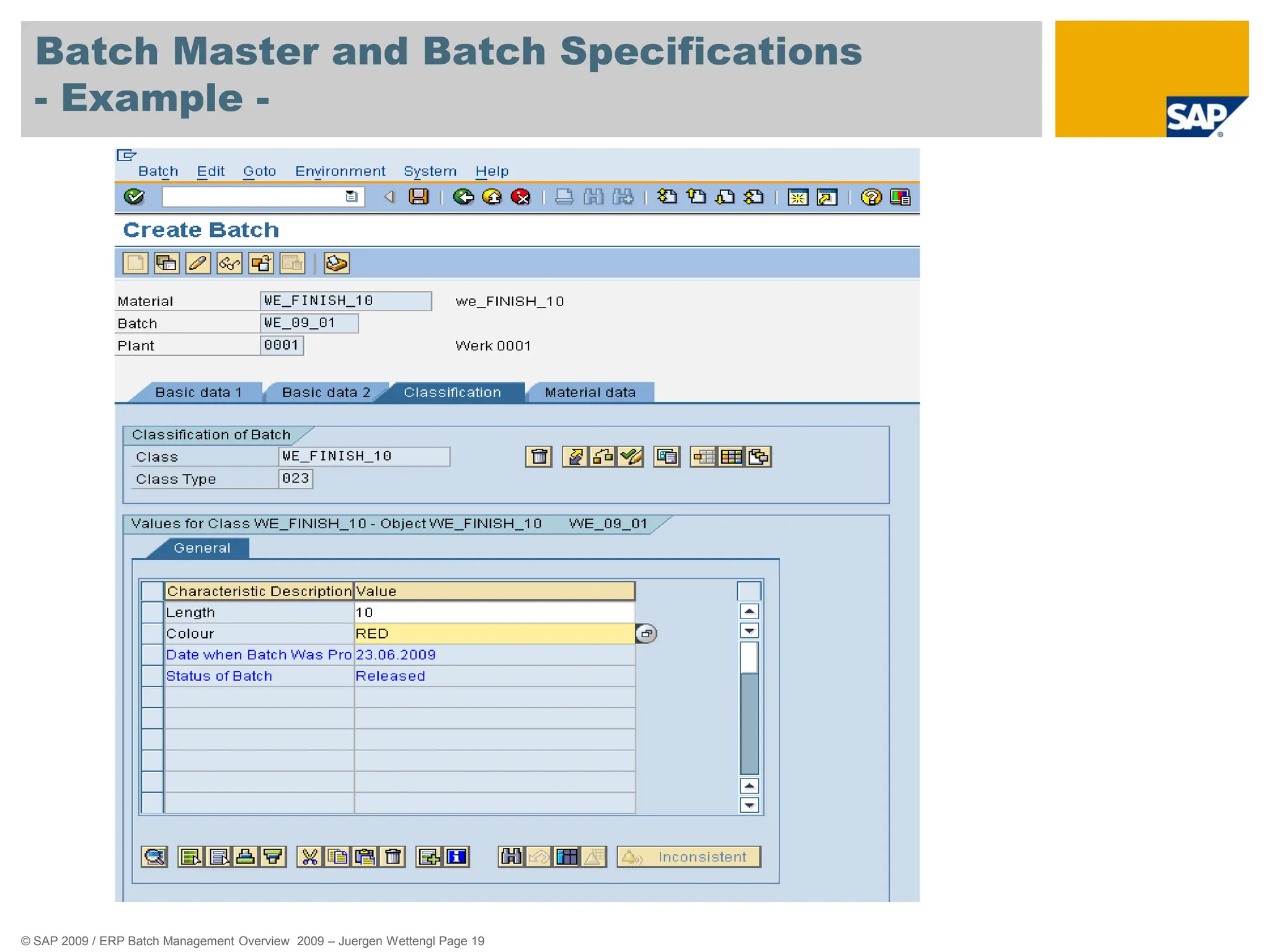

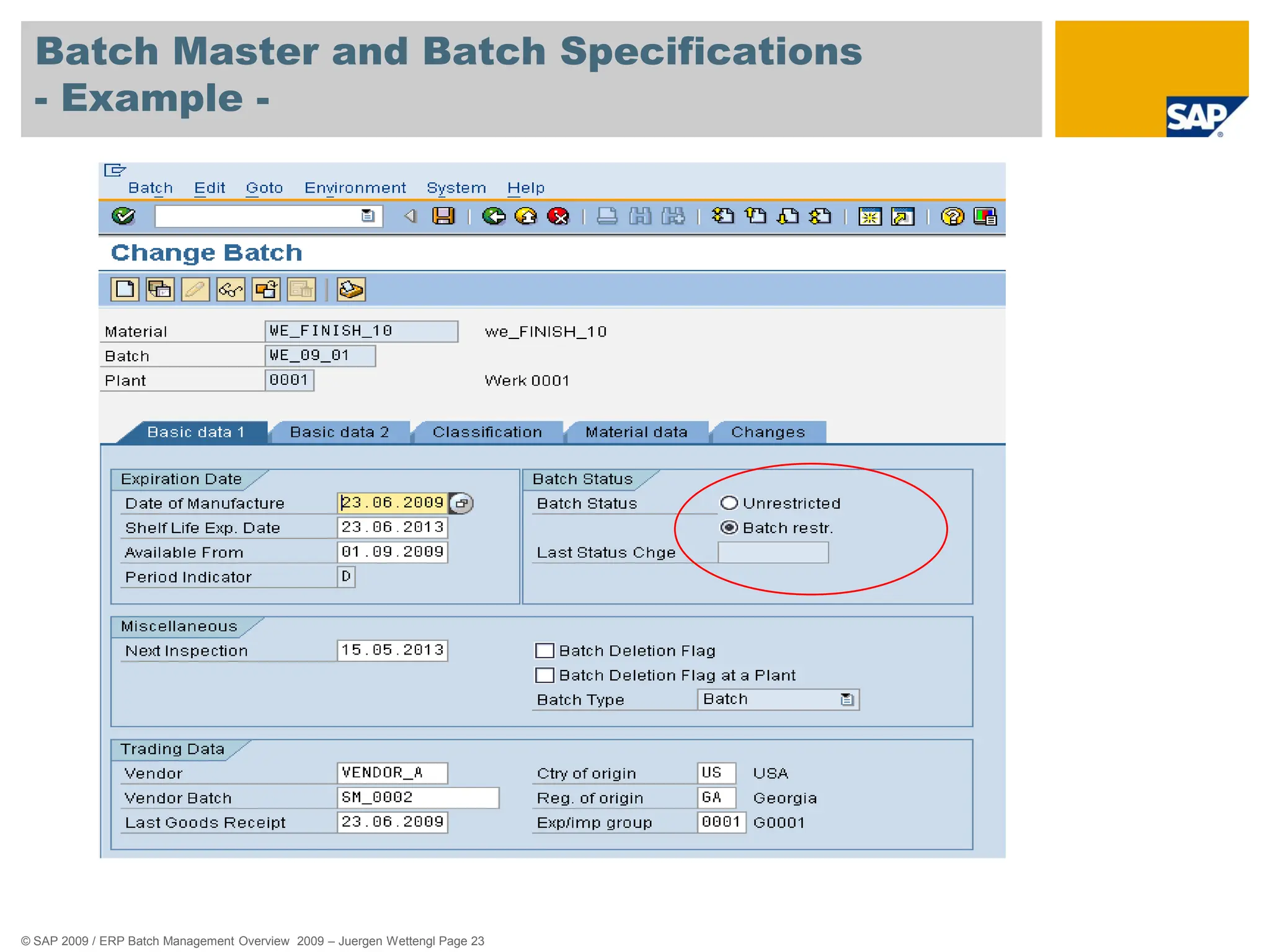

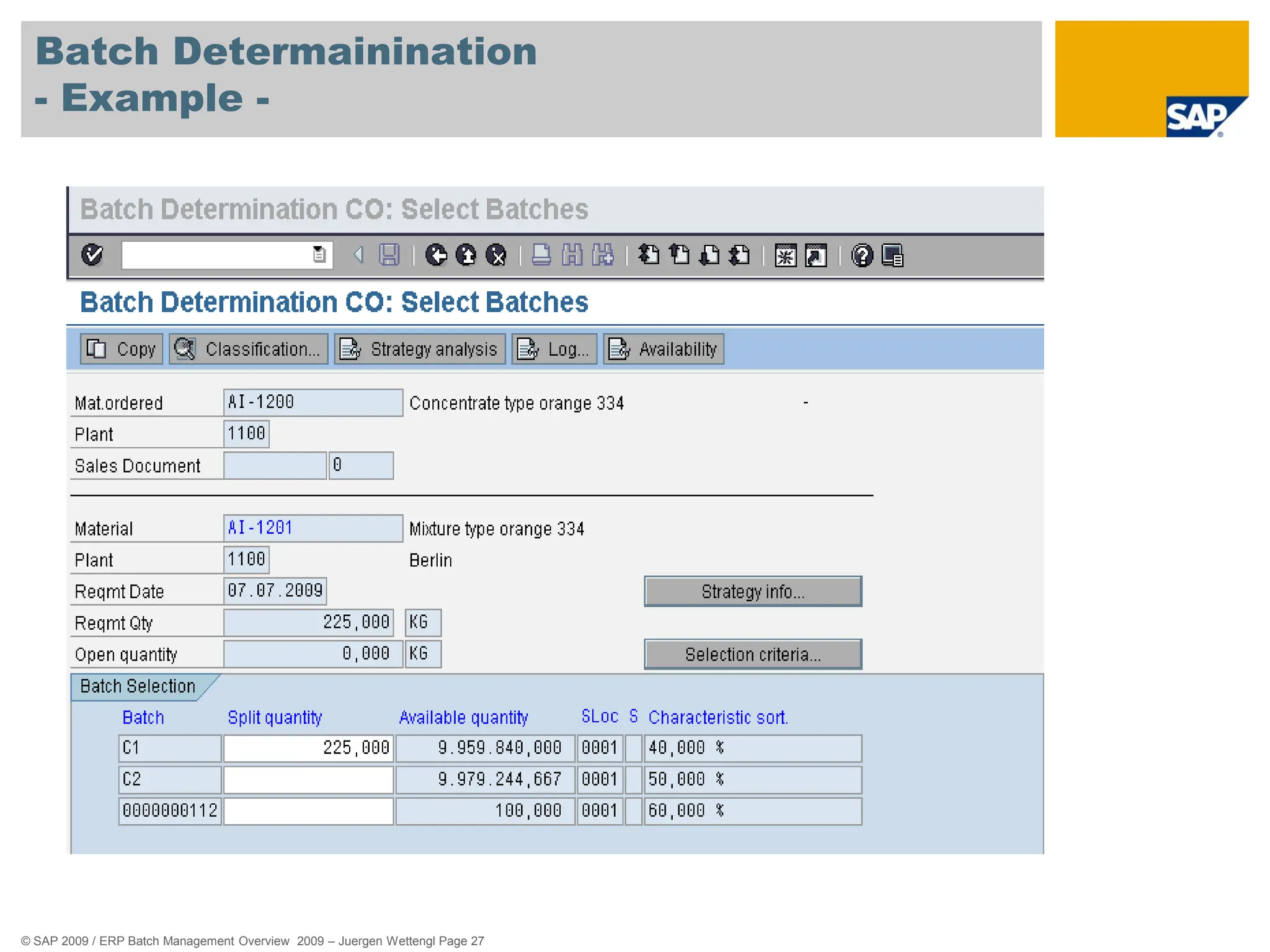

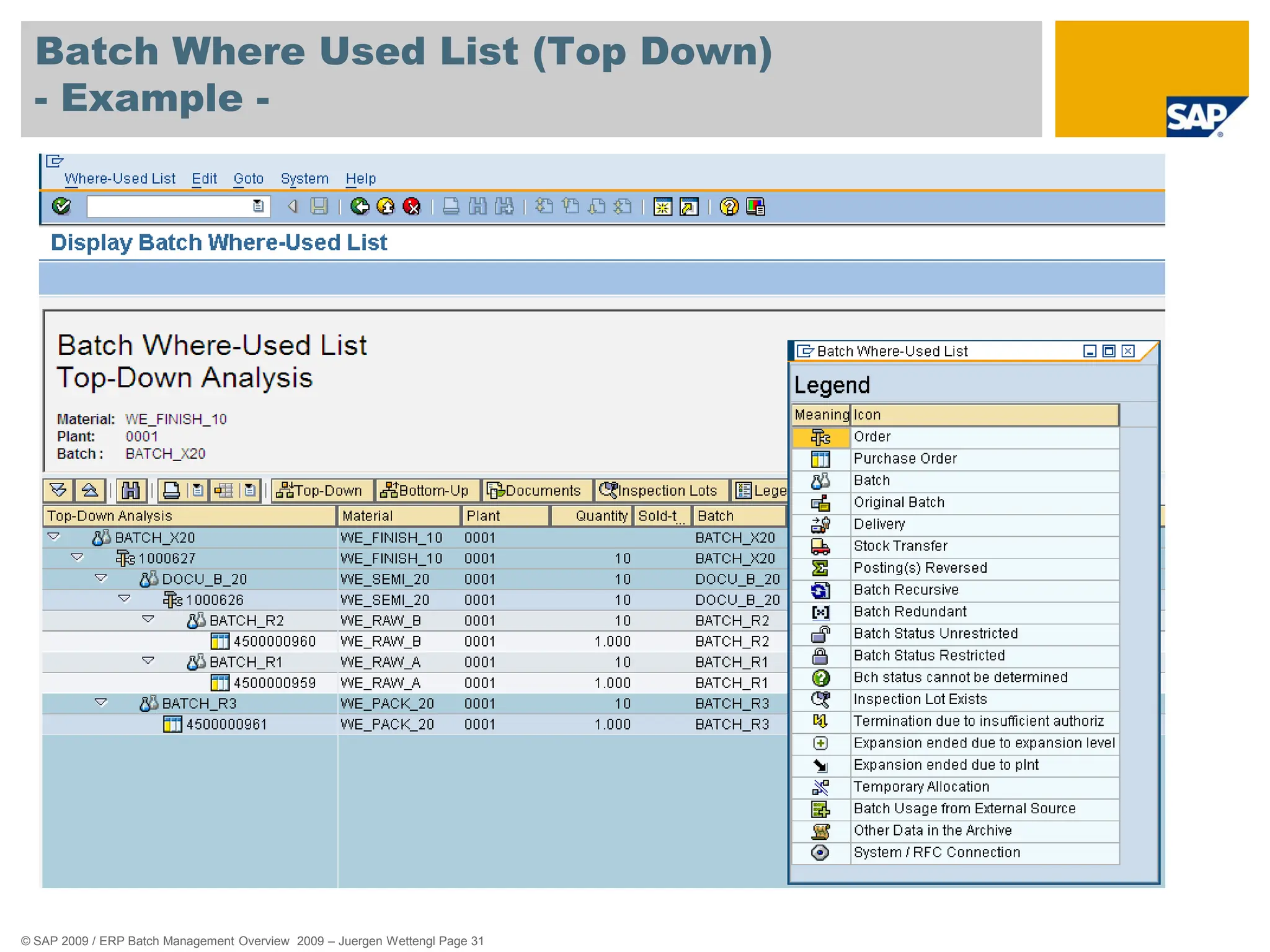

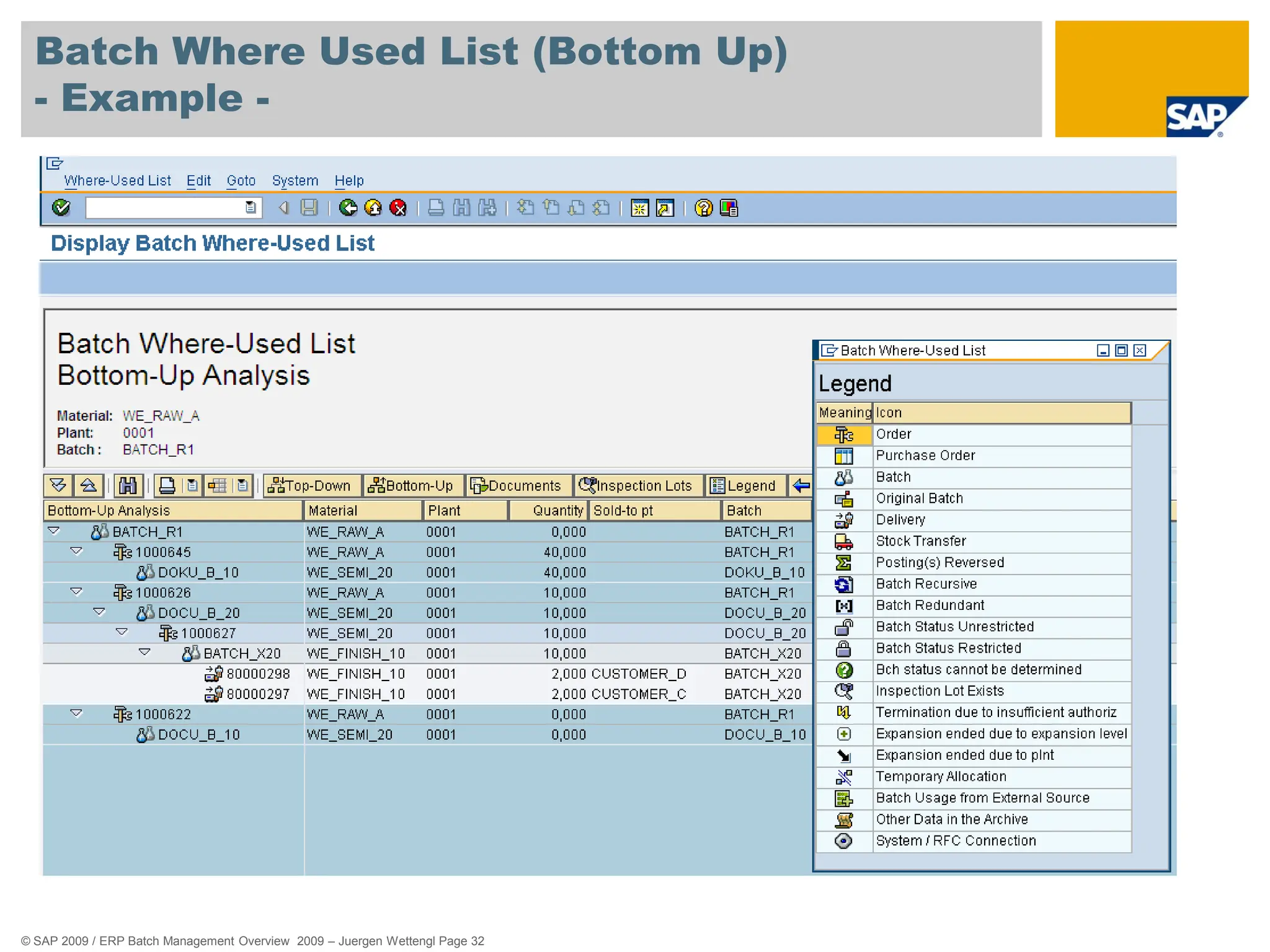

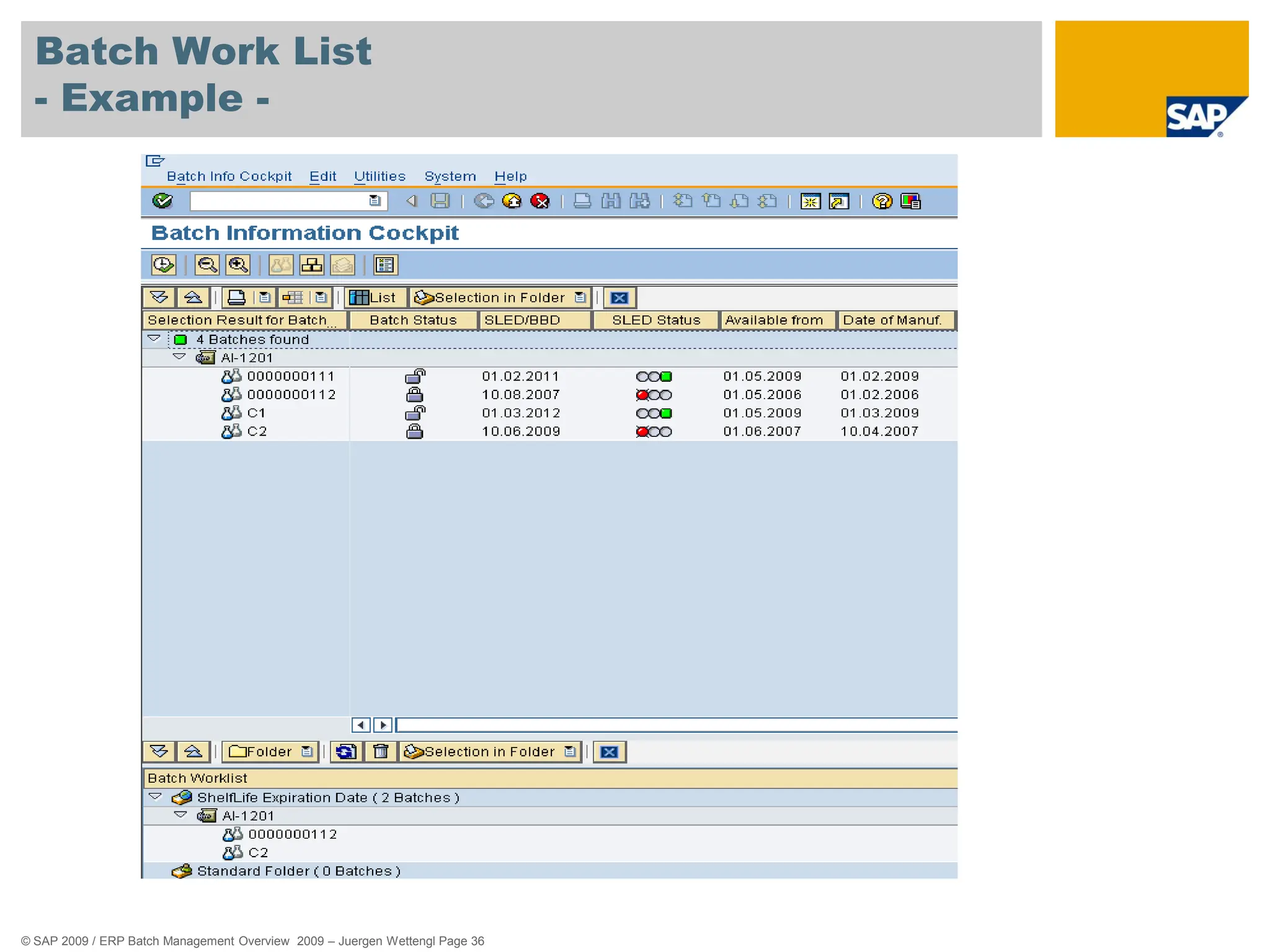

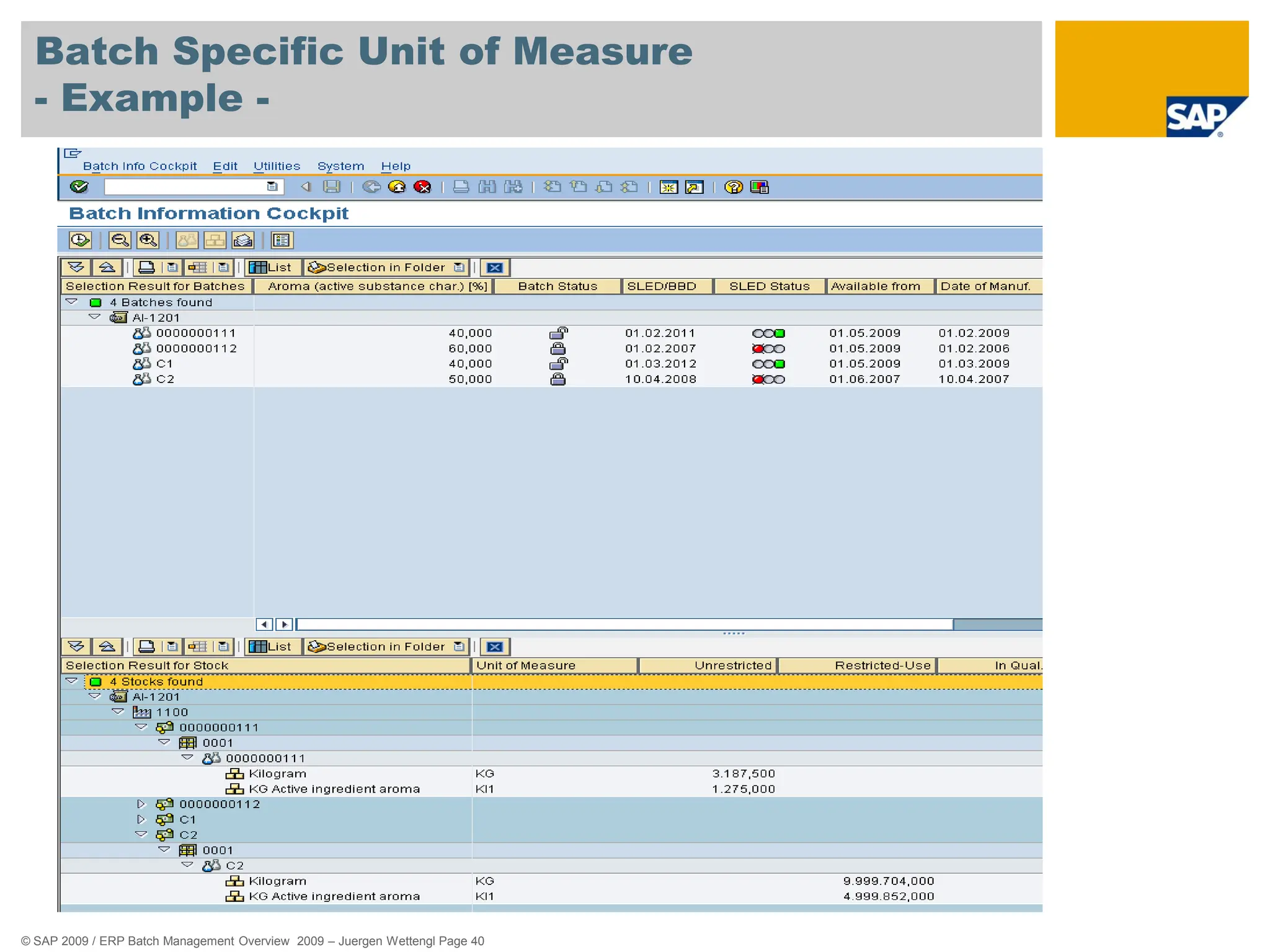

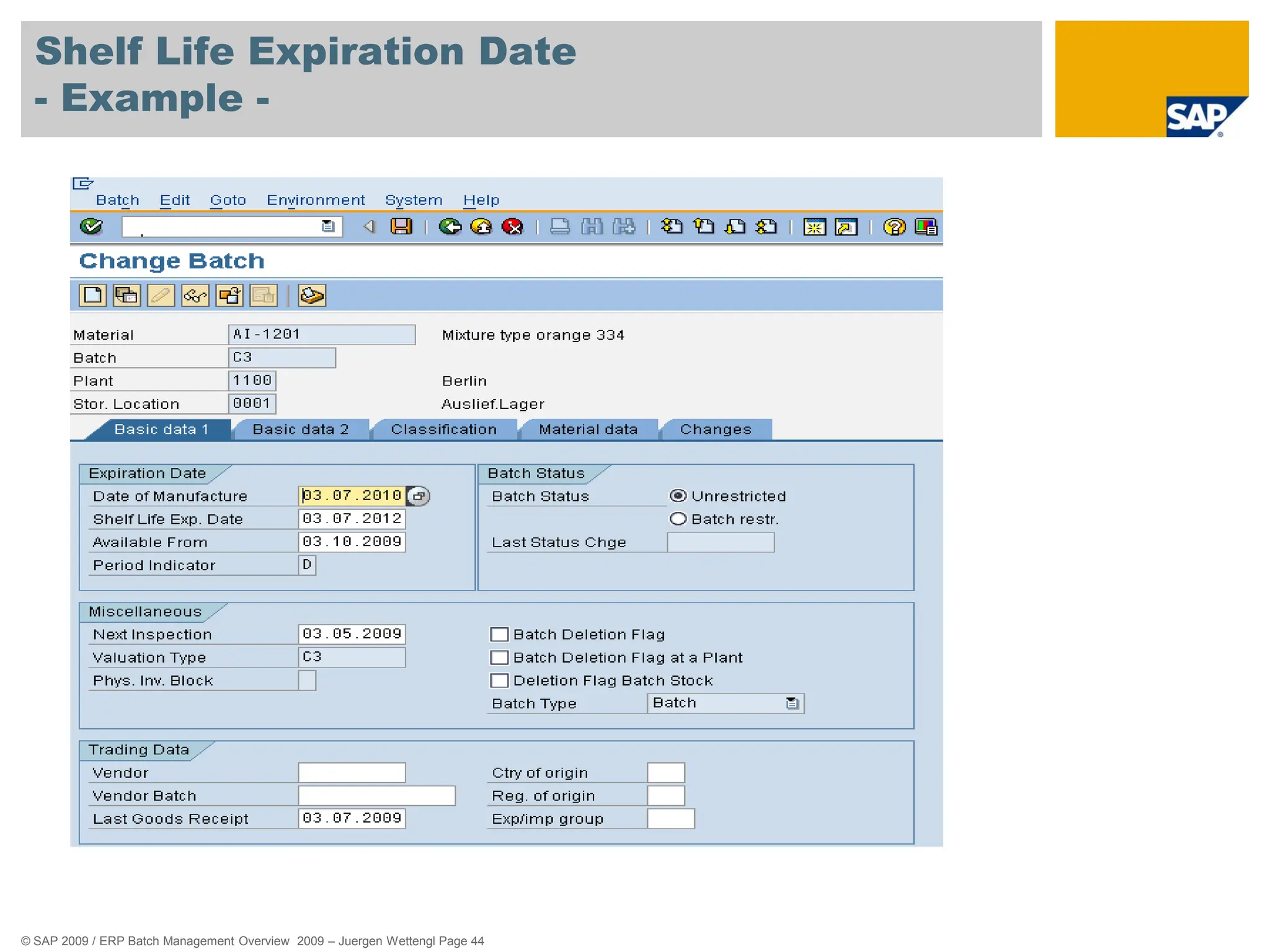

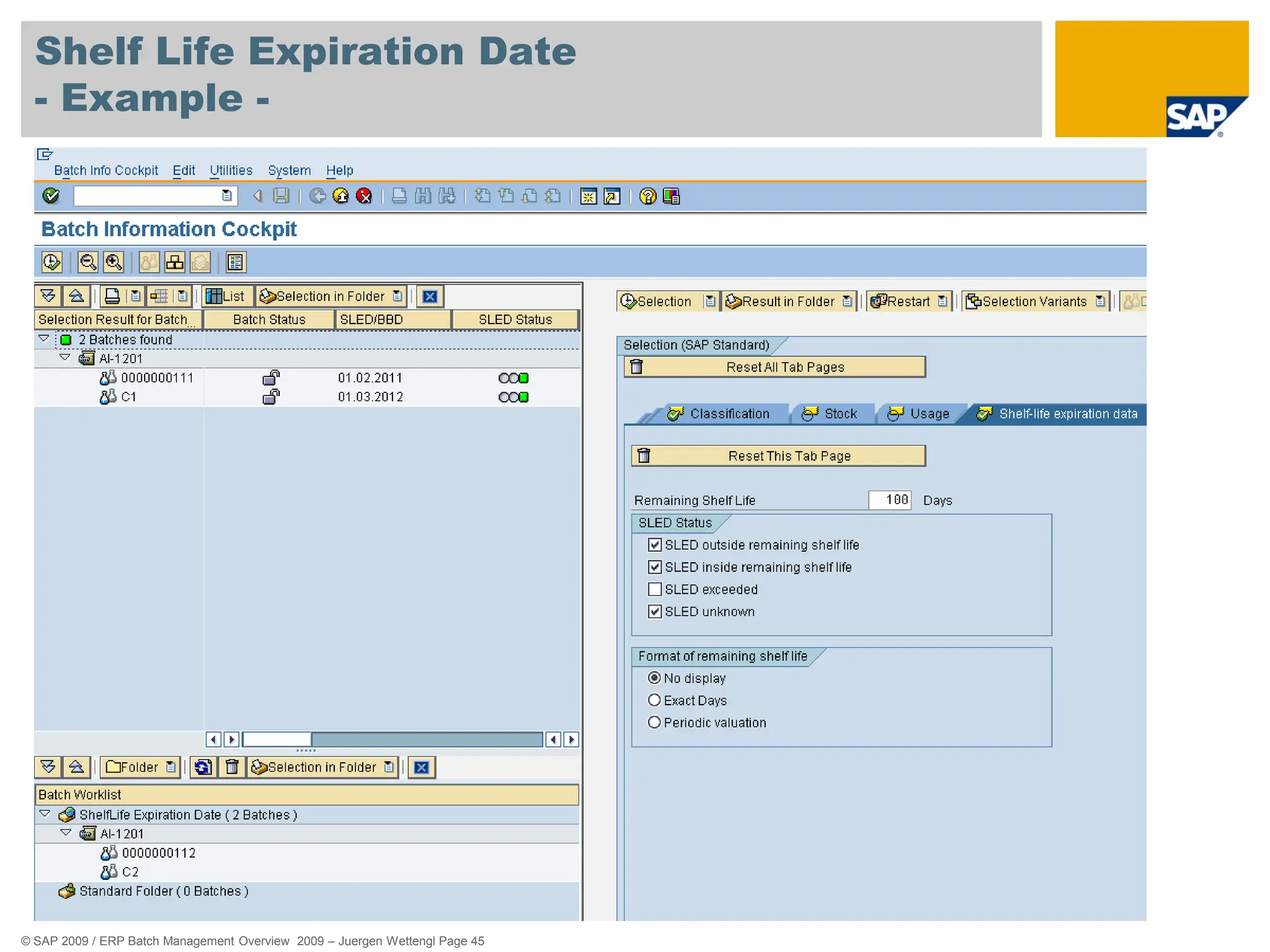

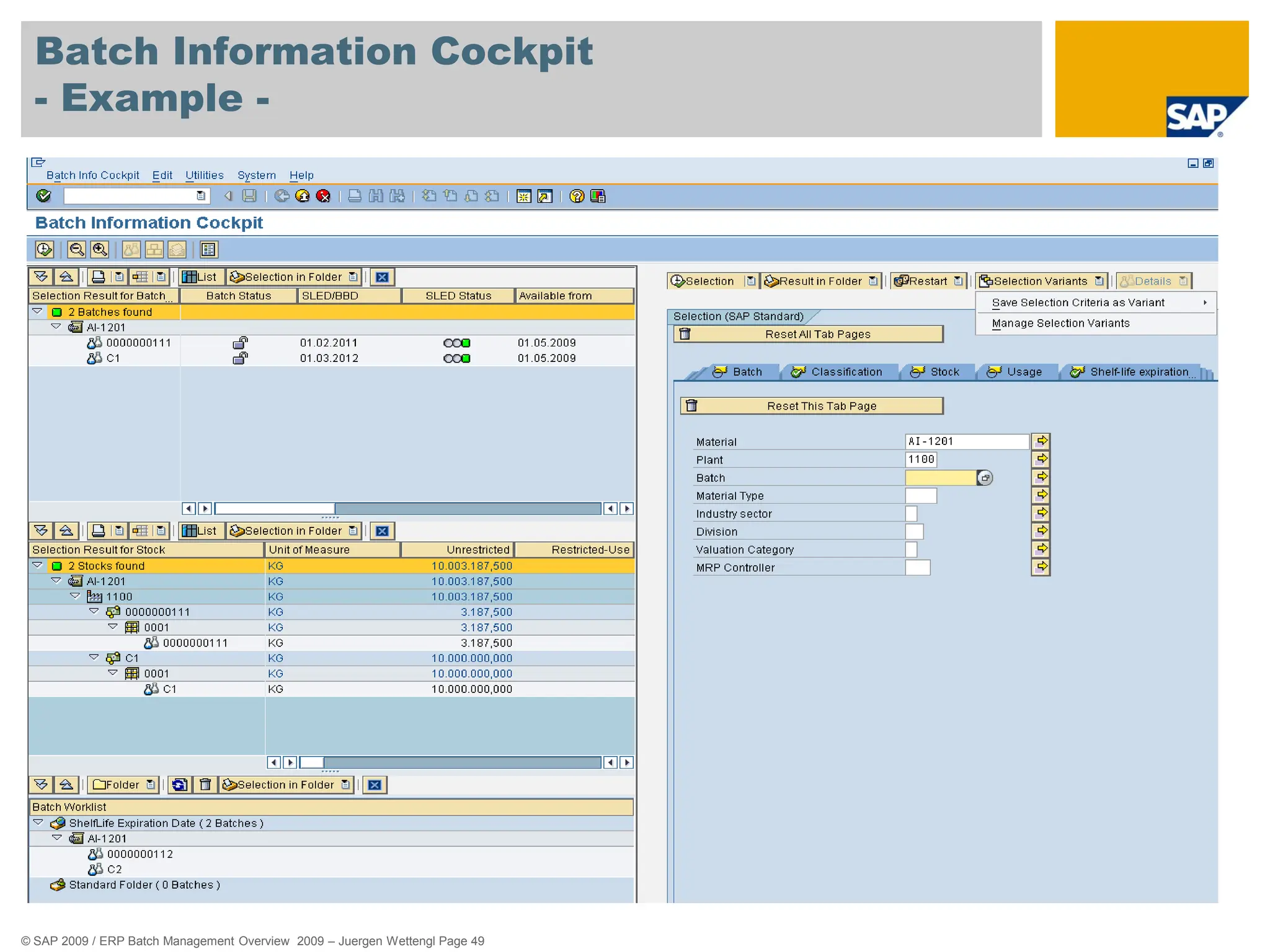

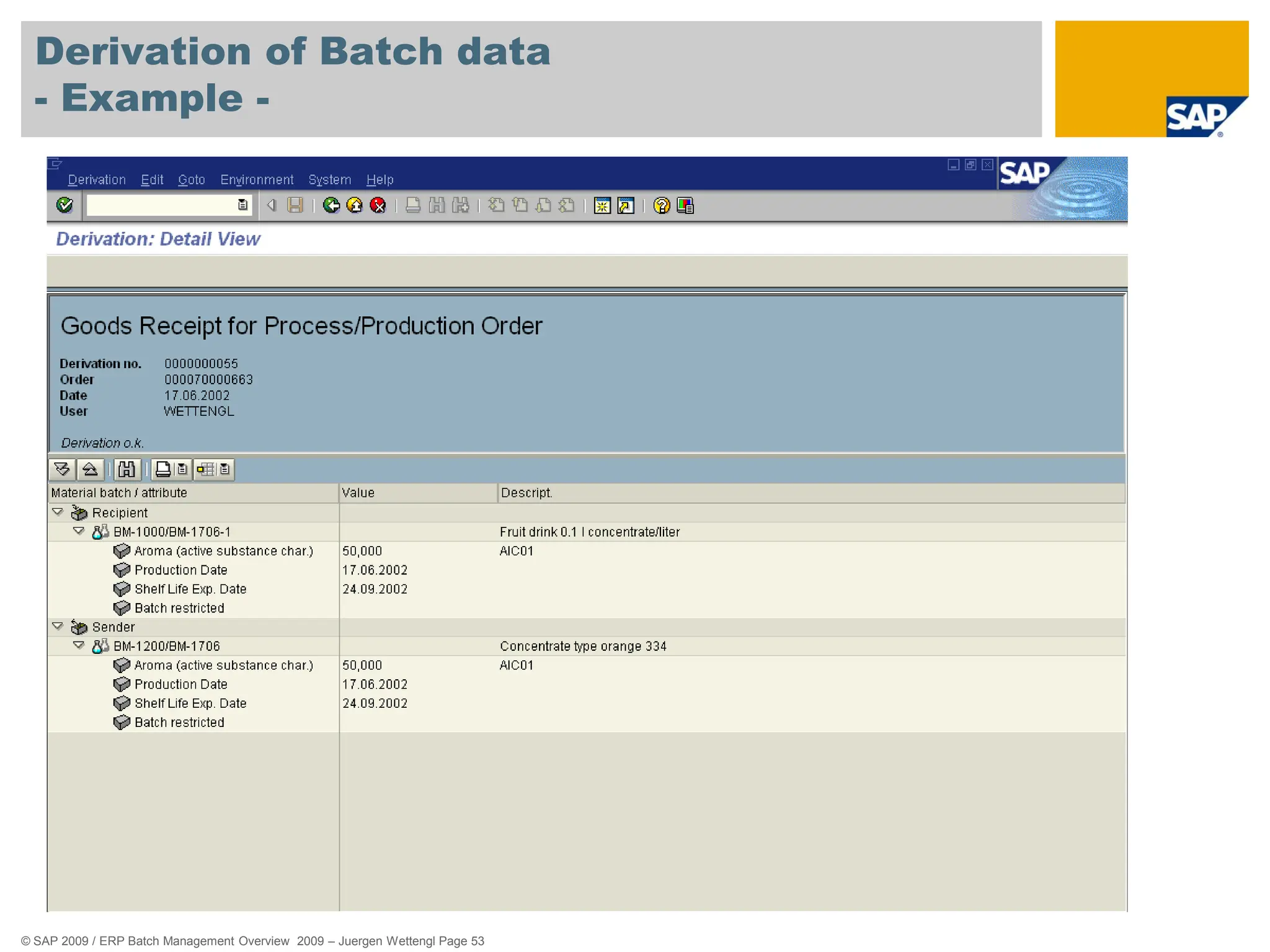

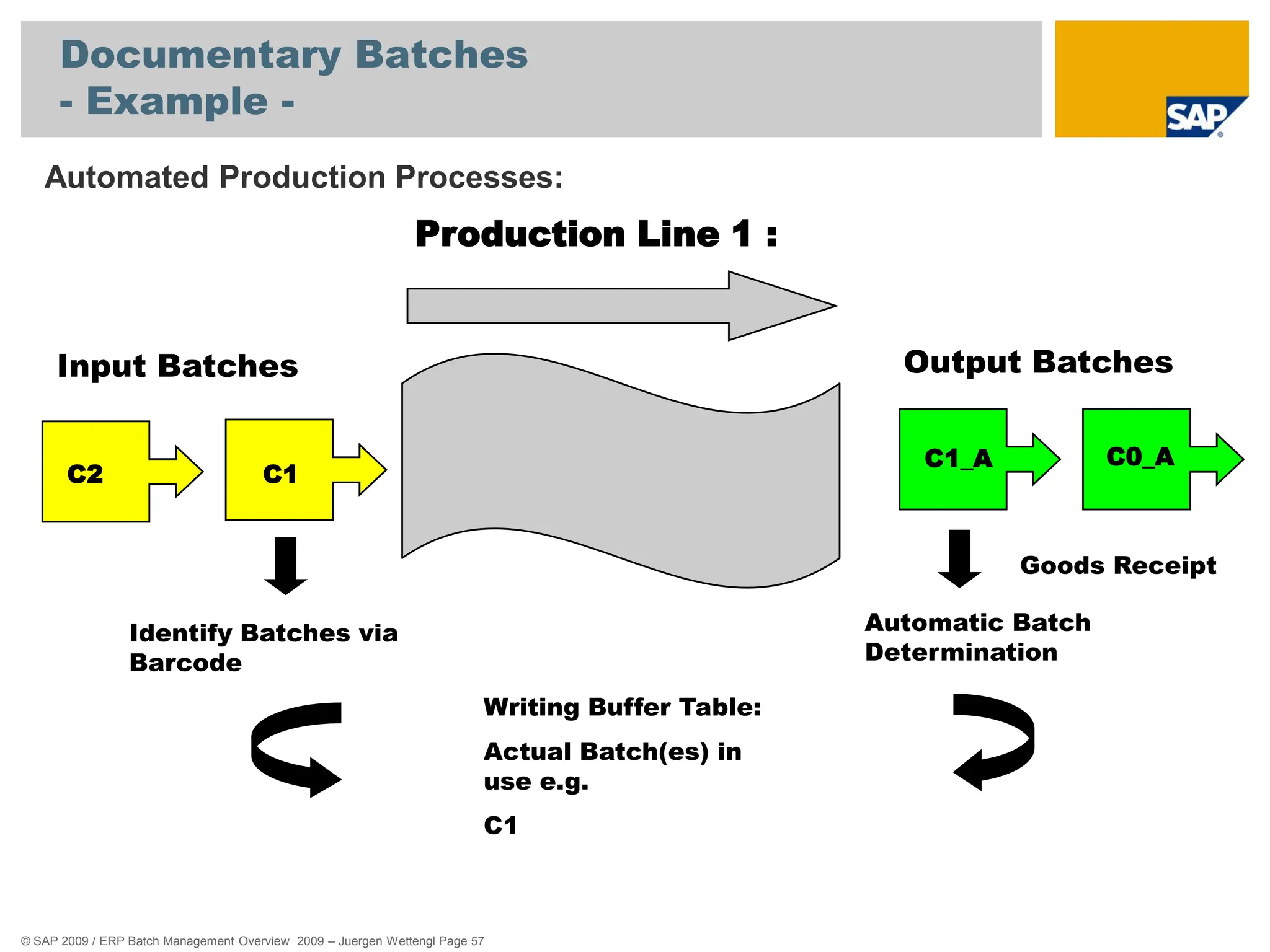

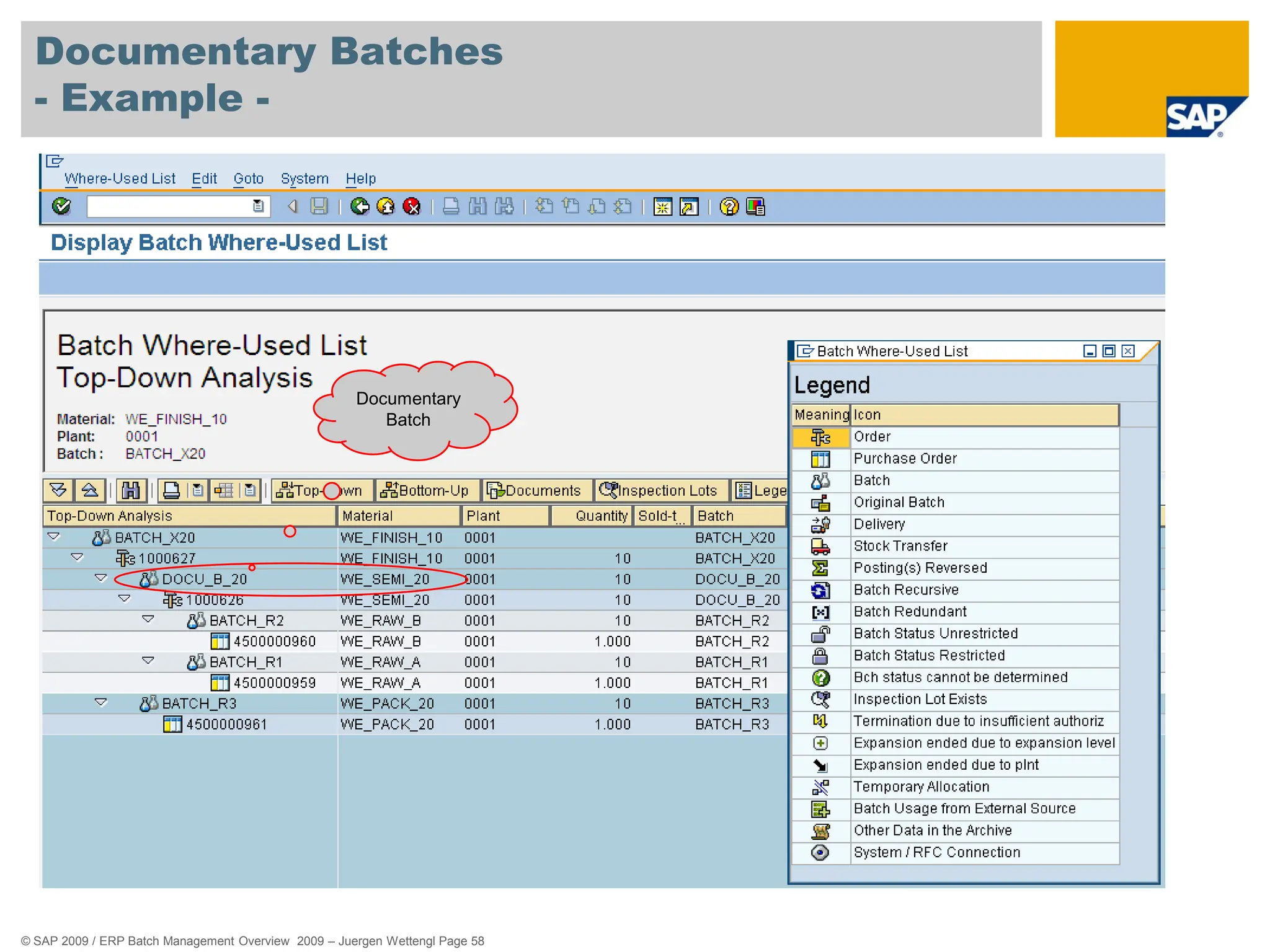

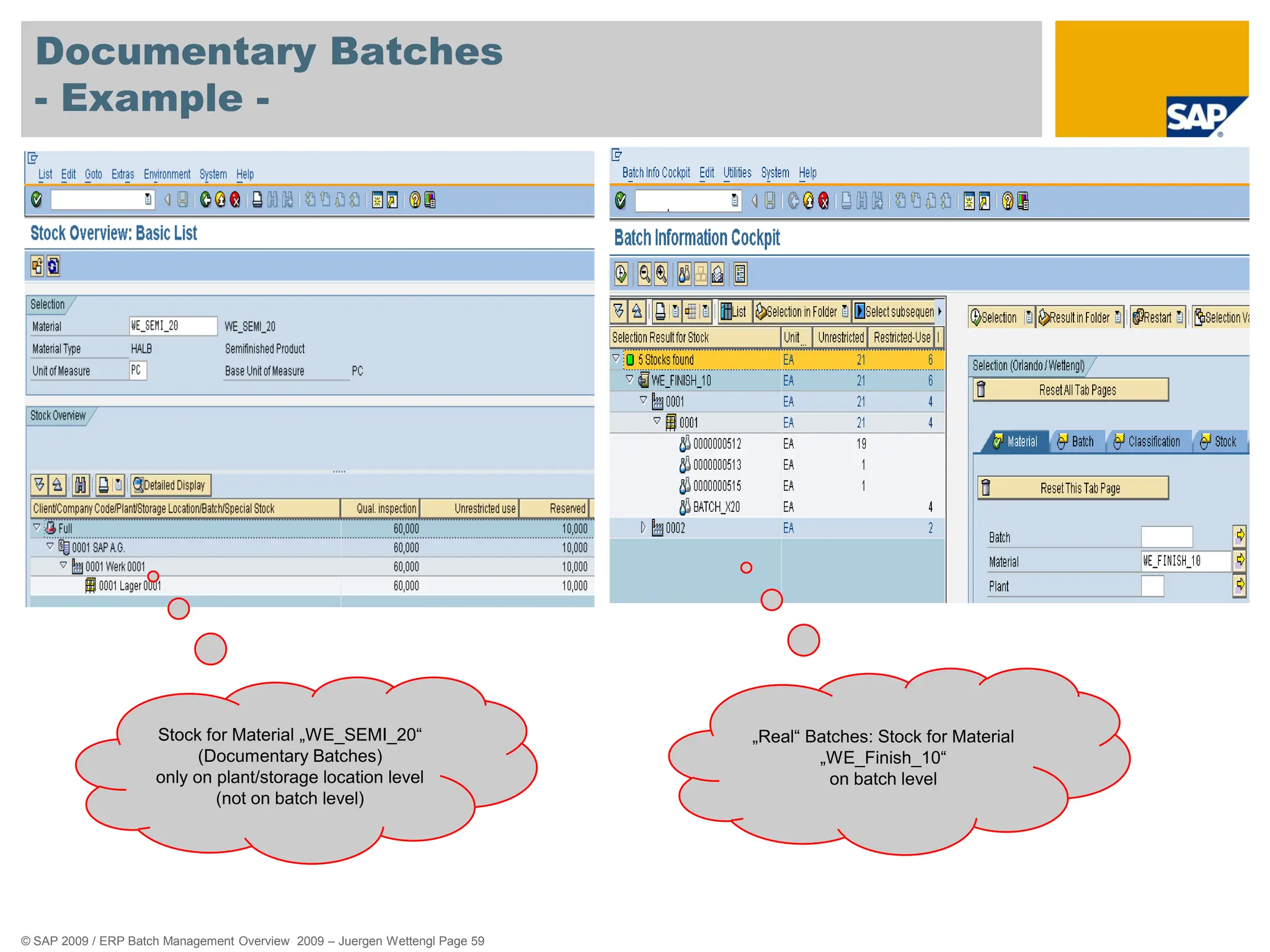

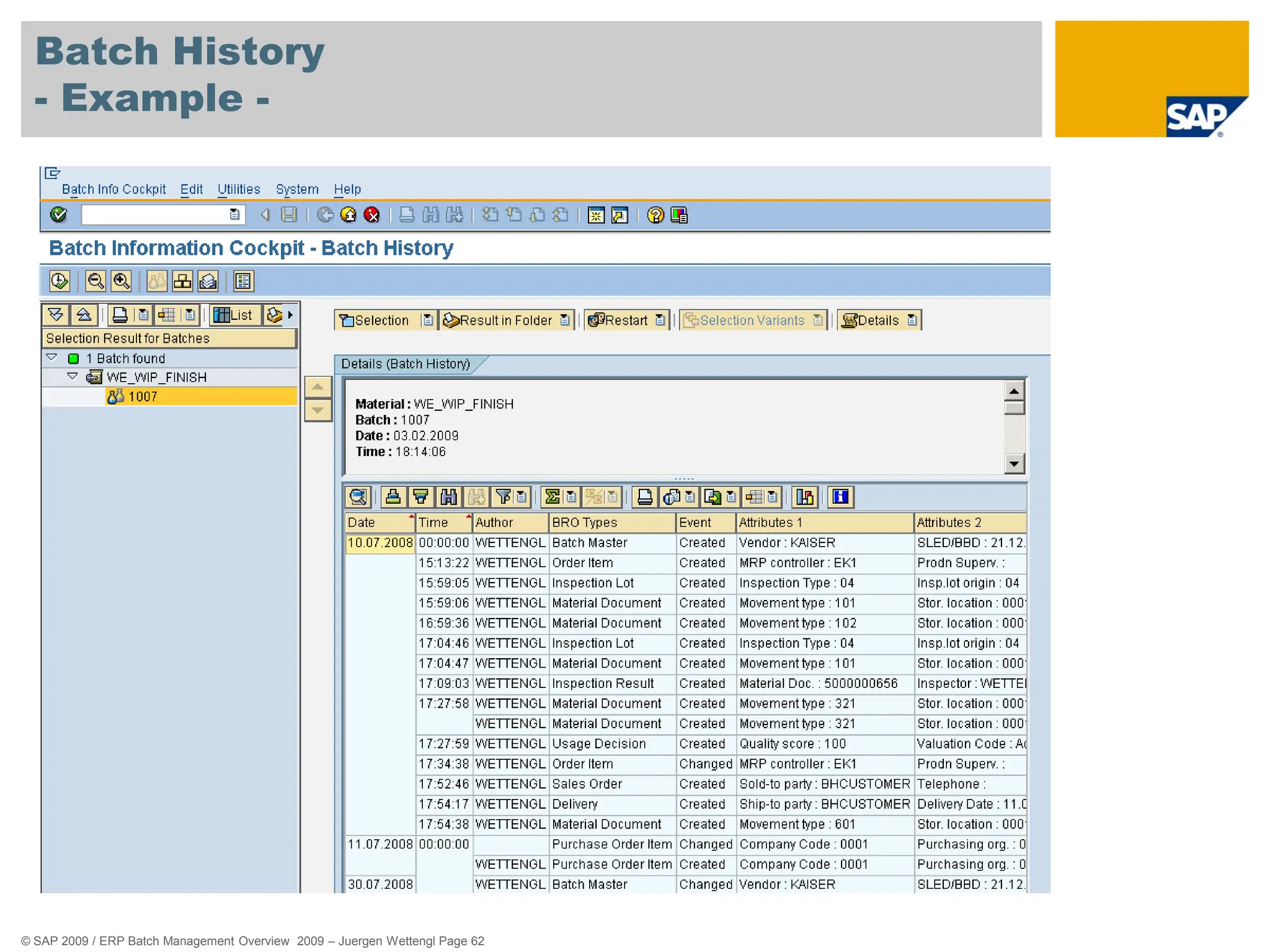

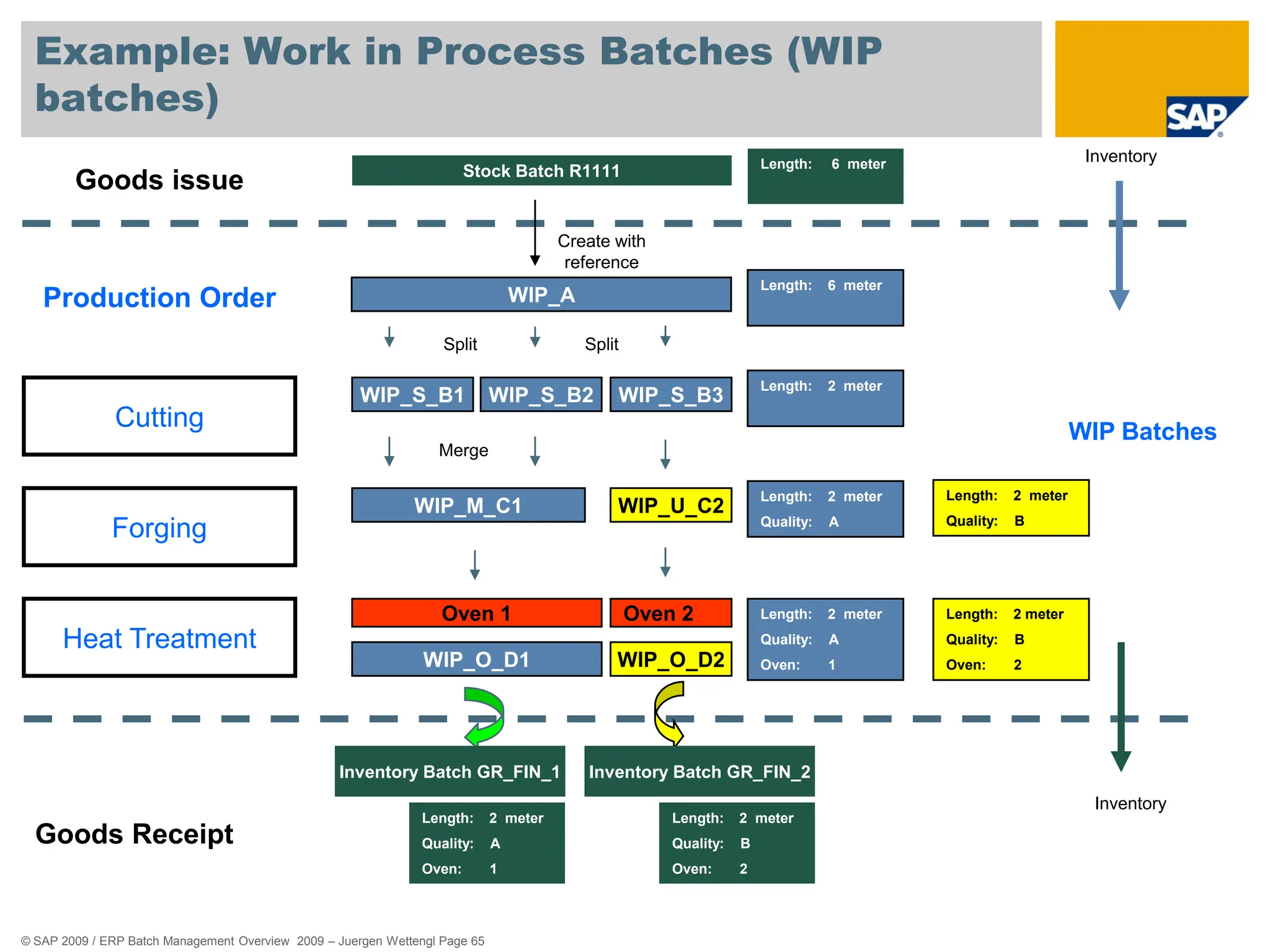

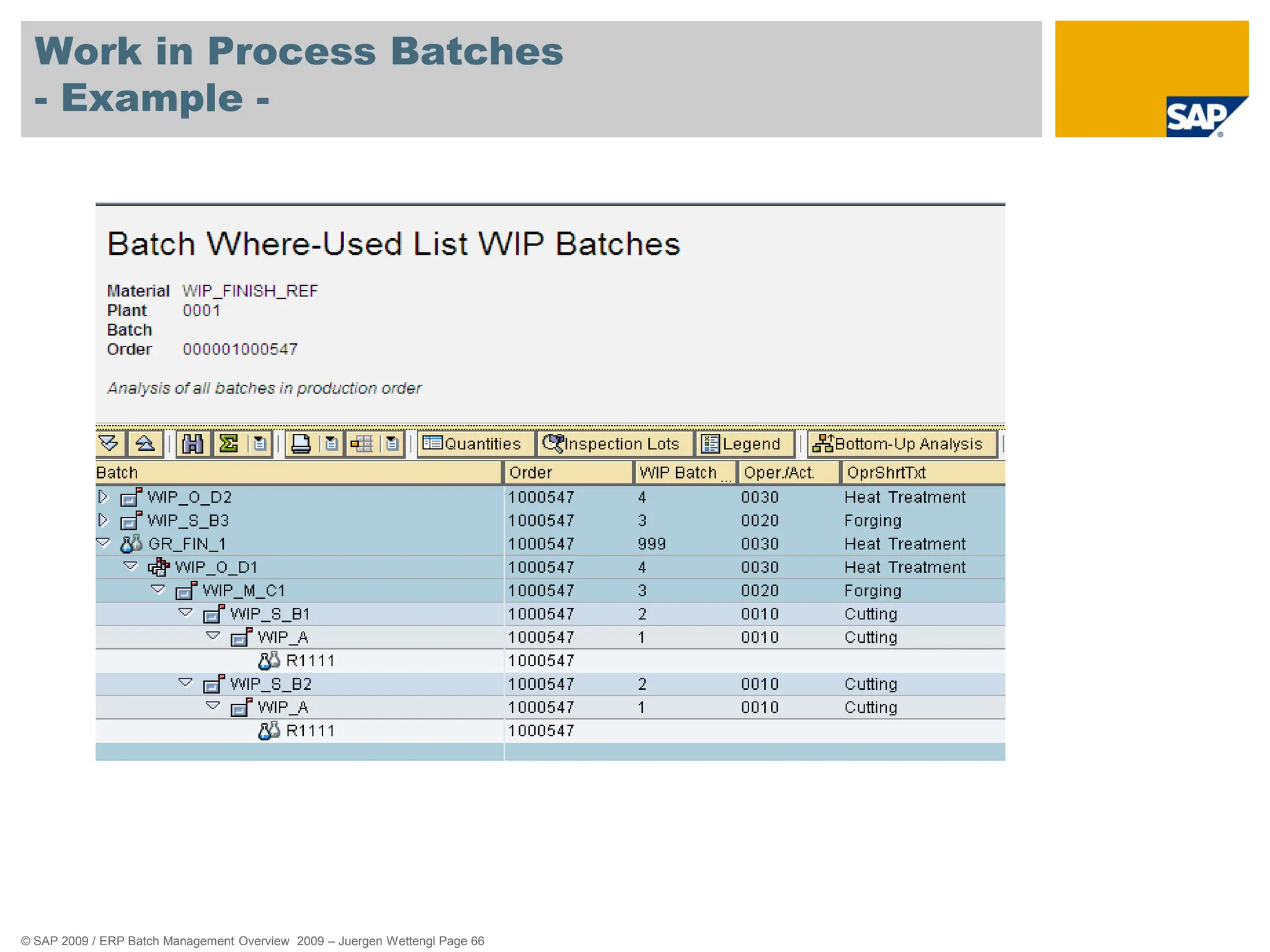

The document provides an overview of ERP batch management capabilities, detailing definitions, batch creation, status management, determination, and traceability throughout production. It explains the importance of uniquely identifying batches, managing batch specifications, and utilizing the batch information cockpit for analysis. The document emphasizes how these functions ensure efficient handling of materials with varying characteristics across different industries.