More Related Content

PDF

Distributed Control System (DCS) Notes PPT

PPT

PPT

PPTX

What is a Distributed Control System? DCS has evolved from the original desc... PPTX

Distributed control system PDF

PLC Training in Noida | PLC Scada Training in Delhi PPTX

Basic understanding of PLC RTU DCS SCADA Similar to Basic of Programable Logic Controller PLC

PPTX

PDF

What id difference between .. PPTX

DCS Simulator configure program and troubleshooting PPTX

PPTX

PPTX

Scada system ( Overview ) PPT

Distributed control system PPT 1 2 3 4 5 PPTX

PPTX

SCADA The Universal Remote for Industrial Control.pptx PPTX

DCS - Distributed Control System PDF

Lecture+9+-+SCADA+Systems.pdf PDF

PPTX

SCADAhjknvbxfbgmmmmmmmmmmmmmmmmmmmmmmm.pptx PPTX

Lecture+9+-+SCADA+Systems.pptx PDF

Practical DNP3 and Modern SCADA Systems PPT

PLC as a digital electronic devic programmable memor PPTX

This ppt is about distributed control system. PPT

PDF

DCS FTKU DSYJKHJ IUGHGJHJHGHFGDFSHGJHGHFGDFSDAFDGFHG PDF

Unit Three.pdfrhykyfgdsfuliuyfgm,i;poiuyrtghkl;ipoiy More from Ahmed Ramadan

PPTX

Basic PLC - Solid introduction _ 22.pptx PPTX

Basic PLC - Solid introduction _ 1 .pptx PPT

pressure-relief- devices and valves basics PDF

Logic Concepts as used in programmable logic controller PDF

Introduction to Programmable Controllers PPT

Supp HAZOP 1 Hazard Analysis Review: The Concept of Risk PPT

Total Solution for Flue Gas Analyzer Series PPTX

Compressor Control and Optimization.pptx PPT

Distributed Control System Operation seminar PPT

FT-IR Instrument Components presentation PDF

Part 2 Analytical Measurements techniques. PDF

Operation Stations in a Distributed Control System Recently uploaded

PDF

MoD_2.pptx solid rockets of the rocket.pdf PPTX

Fuel Injection Pump Test Bench – Precision Testing & Calibration for Diesel E... PDF

Microcontroller Notes Final 2016 April june.pdf PDF

DAA Lab Manual ssit -kavya r.pdf or Digital Design and Analysis of Algorithm ... PPTX

DIFFERENT TYPES OF SRTUCTURAL SYSTEM ANALYSIS PDF

AWS Re:Invent 2025 Recap by FivexL - Guilherme, Vladimir, Andrey PPTX

INTEGRATED COMMUNICATION AND SENSING Presentation.pptx PPTX

ME3592 - Metrology and Measurements - Unit - 1 - Lecture Notes PPTX

traffic safety section seven (Traffic Control and Management) of Act PDF

(en/zhTW) Heterogeneous System Architecture: Design & Performance PDF

Unit Weight in Term of Volumetric Water Content.pdf PDF

Weak Incentives (WINK): The Agent Definition Layer PDF

Plasticity and Structure of Soil/Atterberg Limits.pdf PDF

Enhancing optical fiber communication systems using repetition coding for imp... PPTX

Batch-1(End Semester) Student Of Shree Durga Tech. PPT.pptx PPTX

Why TPM Succeeds in Some Plants and Struggles in Others | MaintWiz PPTX

Presentation-WPS Office.pptx afgouvhyhgfccf PPTX

Why Most SAP PM Implementations Fail — And How High-Reliability Plants Fix It PPTX

This Bearing Didn’t Fail Suddenly — How Vibration Data Predicts Failure Month... PPTX

A professional presentation on Cosmos Bank Heist Basic of Programable Logic Controller PLC

- 1.

- 2.

2 I Copyright© 2024 TPS. All rights reserved

Day 5 Agenda

Overview of typical distributed Control system

architecture

DCS vs. SCADA vs. PLC’s Comparison

The smart instrument

Component in a DCS system

- 3.

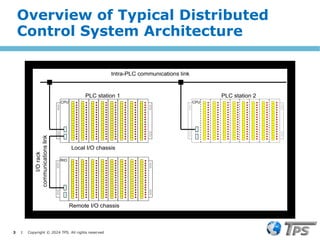

3 I Copyright© 2024 TPS. All rights reserved

CPU

CPU CPU

CPU

RIO

RIO

Intra-PLC communications link

PLC station 1 PLC station 2

Local I/O chassis

Remote I/O chassis

I/O

rack

communications

link

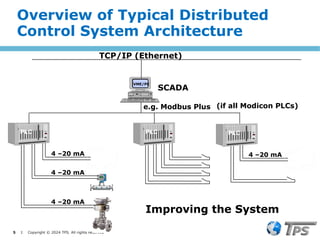

Overview of Typical Distributed

Control System Architecture

- 4.

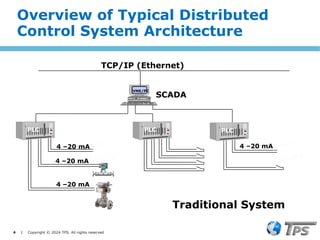

4 I Copyright© 2024 TPS. All rights reserved

VME/PC

4 –20 mA

4 –20 mA

4 –20 mA

PLC PLC

4 –20 mA

PLC

SCADA

TCP/IP (Ethernet)

Traditional System

Overview of Typical Distributed

Control System Architecture

- 5.

5 I Copyright© 2024 TPS. All rights reserved

VME/PC

4 –20 mA

4 –20 mA

4 –20 mA

PLC PLC

4 –20 mA

PLC

SCADA

TCP/IP (Ethernet)

e.g. Modbus Plus (if all Modicon PLCs)

Improving the System

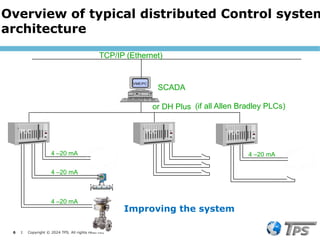

Overview of Typical Distributed

Control System Architecture

- 6.

6 I Copyright© 2024 TPS. All rights reserved

VME/PC

4 –20 mA

4 –20 mA

4 –20 mA

PLC PLC

4 –20 mA

PLC

SCADA

TCP/IP (Ethernet)

or DH Plus (if all Allen Bradley PLCs)

Improving the system

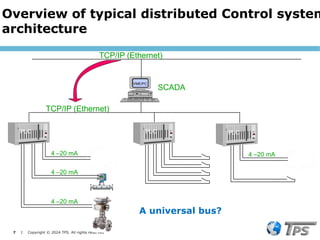

Overview of typical distributed Control system

architecture

- 7.

7 I Copyright© 2024 TPS. All rights reserved

VME/PC

4 –20 mA

4 –20 mA

4 –20 mA

PLC PLC

4 –20 mA

PLC

SCADA

TCP/IP (Ethernet)

TCP/IP (Ethernet)

A universal bus?

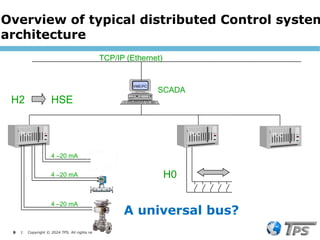

Overview of typical distributed Control system

architecture

- 8.

8 I Copyright© 2024 TPS. All rights reserved

VME/PC

PLC PLC PLC

SCADA

TCP/IP (Ethernet)

H2 HSE

H0

4 –20 mA

4 –20 mA

4 –20 mA

A universal bus?

Overview of typical distributed Control system

architecture

- 9.

9 I Copyright© 2024 TPS. All rights reserved

DCSs have a direct connection to the data source and are primarily

focused on real-time states – concentrating on past and present

process variables.

With direct connection to the hardware device I/O, a very reliable

network connection to equipment is required.

Redundancy is usually handled by parallel equipment – not by

diffusion of information around a distributed database.

A DCS is sequential in nature with alarms generated not when a

point changes but when a process is run.

DCS vs. SCADA vs. PLC’s

– Comparison

- 10.

10 I Copyright© 2024 TPS. All rights reserved

A DCS operator station is closely connected with its I/O signals

through local wiring and communication buses (e.g. Fieldbus).

When DCS operators wish to see information they would

usually make a request directly to the field I/O and gets a

response.

Field events can directly interrupt the system and advise the

operator.

A DCS typically has correspondingly more complexity in its

process-control functionality.

DCS vs. SCADA vs. PLC’s

– Comparison

- 11.

11 I Copyright© 2024 TPS. All rights reserved

In many instances DCSs are not aware of a change in state, but simply

report the current real-time state at the instant the hardware is polled.

Events and alarms (both central concepts in SCADA) are secondary to

process displays.

Therefore, it is often necessary to set up alarms by hand on each point,

and many DCSs have limited alarm filtering.

Because DCSs must have a continuous connection to the hardware,

they are generally deployed only when the system has a very small

geographical footprint, such as a factory or plant.

DCS vs. SCADA vs. PLC’s

– Comparison

- 12.

12 I Copyright© 2024 TPS. All rights reserved

Historically, SCADA systems have focused on control of remote

equipment where telecommunications may be regularly

interrupted.

Consequently, SCADA systems are indirectly connected via a

database to the field equipment and can continue operating even

when telecommunications are temporarily lost.

Further more, SCADA systems typically incorporate complex

polling capabilities to help address telecommunication restrictions.

SCADA systems are thus said to be data-centric and have a

database driven architecture.

DCS vs. SCADA vs. PLC’s

– Comparison

- 13.

13 I Copyright© 2024 TPS. All rights reserved

Unlike DCSs that are state driven, SCADA systems are event

driven, with change of state (COS) driving the functionality of the

system

COS is also the main criteria in data gathering and presentation.

COS also focuses SCADA functionality on alarms, which are

typically automatically set on all points and event logs.

Consequently, a large part of a SCADA system's functionality is

centred on complex filtering for alarms and event logs.

DCS vs. SCADA vs. PLC’s

– Comparison

- 14.

14 I Copyright© 2024 TPS. All rights reserved

The essential difference is that a SCADA system transfers data

and control signals over a potentially slow, unreliable

communications medium – with redundancy usually handled in

a distributed manner.

Thus, a SCADA system must continue to operate when field

communications have failed and the ‘quality’ of the data shown

to the operator is an important facet of system operation.

The system thus needs to maintain a database of ‘last known

good values’ for prompt operator display.

DCS vs. SCADA vs. PLC’s

– Comparison

- 15.

15 I Copyright© 2024 TPS. All rights reserved

Because SCADA is oriented towards data gathering its focus is on

the control centre and operators.

SCADA systems thus usually provide special ‘event’ processing

mechanisms to handle conditions that occur between data

acquisition periods.

It frequently needs to carry out event processing and data quality

validation.

DCS vs. SCADA vs. PLC’s

– Comparison

- 16.

16 I Copyright© 2024 TPS. All rights reserved

The roles of a SCADA and DCS are quite different and it is rarely

possible for a single system to perform both functions.

Many industries use both DCS and SCADA products.

The operator stations for each product line can use the same

UNIX workstations.

Further, the systems share data and thus form a composite

SCADA/DCS system.

Today, several manufacturers offer hybrid systems that combine

the best features of both the traditional heritage DCS with that of

a modern SCADA-based systems.

DCS vs. SCADA vs. PLC’s

– Comparison

- 17.

17 I Copyright© 2024 TPS. All rights reserved

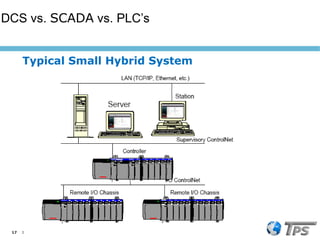

Typical Small Hybrid System

DCS vs. SCADA vs. PLC’s

- 18.

18 I Copyright© 2024 TPS. All rights reserved

VME/PC

PLC PLC PLC

SCADA

TCP/IP (Ethernet)

H2 HSE

H0

H1

A universal bus?

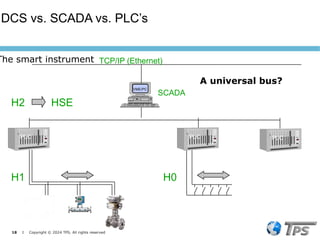

The smart instrument

DCS vs. SCADA vs. PLC’s

- 19.

19 I Copyright© 2024 TPS. All rights reserved

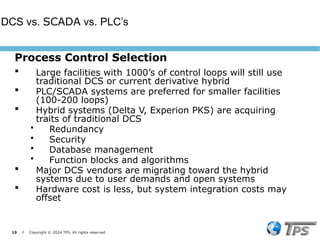

Process Control Selection

Large facilities with 1000’s of control loops will still use

traditional DCS or current derivative hybrid

PLC/SCADA systems are preferred for smaller facilities

(100-200 loops)

Hybrid systems (Delta V, Experion PKS) are acquiring

traits of traditional DCS

• Redundancy

• Security

• Database management

• Function blocks and algorithms

Major DCS vendors are migrating toward the hybrid

systems due to user demands and open systems

Hardware cost is less, but system integration costs may

offset

DCS vs. SCADA vs. PLC’s

- 20.

20 I Copyright© 2024 TPS. All rights reserved

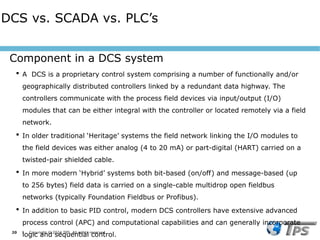

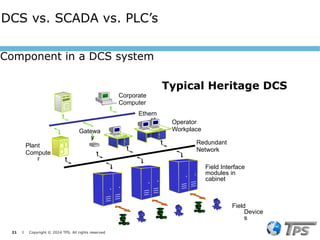

A DCS is a proprietary control system comprising a number of functionally and/or

geographically distributed controllers linked by a redundant data highway. The

controllers communicate with the process field devices via input/output (I/O)

modules that can be either integral with the controller or located remotely via a field

network.

In older traditional ‘Heritage’ systems the field network linking the I/O modules to

the field devices was either analog (4 to 20 mA) or part-digital (HART) carried on a

twisted-pair shielded cable.

In more modern ‘Hybrid’ systems both bit-based (on/off) and message-based (up

to 256 bytes) field data is carried on a single-cable multidrop open fieldbus

networks (typically Foundation Fieldbus or Profibus).

In addition to basic PID control, modern DCS controllers have extensive advanced

process control (APC) and computational capabilities and can generally incorporate

logic and sequential control.

Component in a DCS system

DCS vs. SCADA vs. PLC’s

- 21.

21 I Copyright© 2024 TPS. All rights reserved

Typical Heritage DCS

Field Interface

modules in

cabinet

Field

Device

s

Ethern

et

Redundant

Network

Corporate

Computer

Plant

Compute

r

Operator

Workplace

Gatewa

y

Component in a DCS system

DCS vs. SCADA vs. PLC’s

- 22.

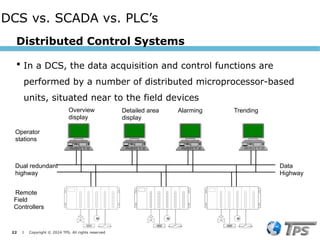

22 I Copyright© 2024 TPS. All rights reserved

Distributed Control Systems

In a DCS, the data acquisition and control functions are

performed by a number of distributed microprocessor-based

units, situated near to the field devices

Data

Highway

Operator

stations

M

M M

M M

M

Dual redundant

highway

Remote

Field

Controllers

Overview

display

Detailed area

display

Alarming Trending

DCS vs. SCADA vs. PLC’s

- 23.

23 I Copyright© 2024 TPS. All rights reserved

Distributed Control Systems

Typically referred to as Heritage systems

Control functions, simulation and optimization

routines are ‘distributed’ to field controllers

mounted in remote field locations

Field Controllers are microprocessors capable of

performing a variety of algorithms on the control

signal

These include:

• classic PID functions

• ratio,

• linearization,

• cascade,

• alarm and shutdown

Component in a DCS system

DCS vs. SCADA vs. PLC’s

- 24.

- 25.

25 I Copyright© 2024 TPS. All rights reserved

What’s gone wrong?

Exercise

Valve jammed open

Level transmitter giving false low-level signal

Control loop left on manual with valve open

Leaking control valve and pump out stage shut

down

– Alarm & shutdown logic diagrams

PLC applications in Automations

- 26.

26 I Copyright© 2024 TPS. All rights reserved

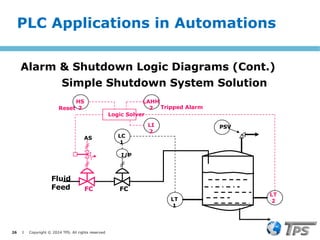

Simple Shutdown System Solution

LT

1

PSV

LC

1

I/P

FC

Fluid

Feed FC

Logic Solver

LT

2

LAHH

2

AS

HS

2

Reset

LI

2

Tripped Alarm

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 27.

27 I Copyright© 2024 TPS. All rights reserved

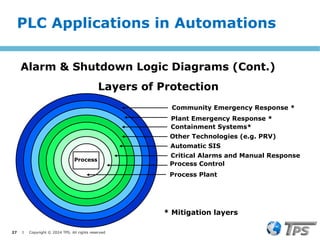

Layers of Protection

Process

Plant Emergency Response *

Other Technologies (e.g. PRV)

Automatic SIS

Critical Alarms and Manual Response

Process Plant

* Mitigation layers

Community Emergency Response *

Containment Systems*

Process Control

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 28.

28 I Copyright© 2024 TPS. All rights reserved

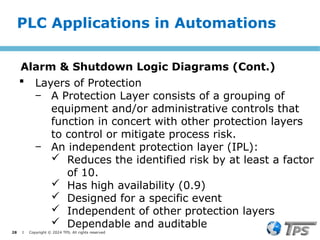

Layers of Protection

‒ A Protection Layer consists of a grouping of

equipment and/or administrative controls that

function in concert with other protection layers

to control or mitigate process risk.

‒ An independent protection layer (IPL):

Reduces the identified risk by at least a factor

of 10.

Has high availability (0.9)

Designed for a specific event

Independent of other protection layers

Dependable and auditable

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 29.

29 I Copyright© 2024 TPS. All rights reserved

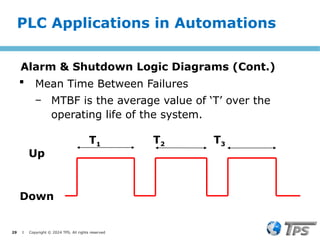

Mean Time Between Failures

‒ MTBF is the average value of ‘T’ over the

operating life of the system.

T1 T2 T3

Up

Down

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 30.

30 I Copyright© 2024 TPS. All rights reserved

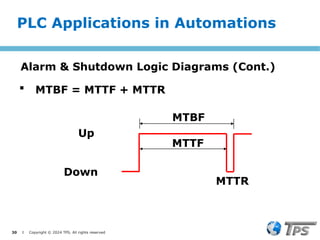

MTBF = MTTF + MTTR

MTTF

MTBF

Up

Down

MTTR

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 31.

31 I Copyright© 2024 TPS. All rights reserved

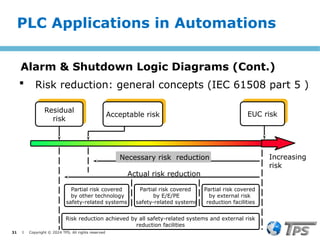

Risk reduction achieved by all safety-related systems and external risk

reduction facilities

Residual

risk

Acceptable risk EUC risk

Necessary risk reduction

Actual risk reduction

Increasing

risk

Partial risk covered

by external risk

reduction facilities

Partial risk covered

by E/E/PE

safety-related systems

Partial risk covered

by other technology

safety-related systems

Risk reduction: general concepts (IEC 61508 part 5 )

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 32.

32 I Copyright© 2024 TPS. All rights reserved

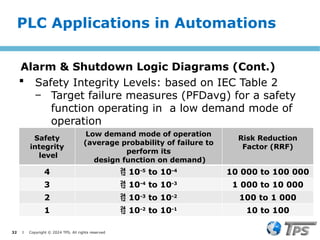

Safety Integrity Levels: based on IEC Table 2

‒ Target failure measures (PFDavg) for a safety

function operating in a low demand mode of

operation

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

Safety

integrity

level

Low demand mode of operation

(average probability of failure to

perform its

design function on demand)

Risk Reduction

Factor (RRF)

4 10-5

to 10-4

10 000 to 100 000

3 10-4

to 10-3

1 000 to 10 000

2 10-3

to 10-2

100 to 1 000

1 10-2

to 10-1

10 to 100

- 33.

33 I Copyright© 2024 TPS. All rights reserved

SIL determination

‒ Safety Integrity Level (SIL) is a basic concept

‒ SIL defines the level of safety performance for a

SIS

‒ SILs are defined as 1, 2, or 3. (and level 4 for

IEC61508 standards)

‒ The higher the SIL, the better the safety

performance of the SIS

‒ Better SIS performance is achieved by higher

availability of the safety function

PLC Applications in Automations

Alarm & Shutdown Logic Diagrams (Cont.)

- 34.

34 I Copyright© 2024 TPS. All rights reserved

Sequential functional chart, or SFC, is a graphical

“language” that provides a diagrammatic

representation of control sequences in a program.

Basically, sequential function chart is a flowchart-like

framework that can organize the subprograms or

subroutines (programmed in LD, FBD, IL, and/or ST)

that form the control program. SFC is particularly

useful for sequential control operations, where a

program flows from one step to another once a

condition has been satisfied (TRUE or FALSE).

PLC Applications in Automations

Sequence Control Program

- 35.

35 I Copyright© 2024 TPS. All rights reserved

The SFC programming framework contains three

main elements that organize the control program:

‒ Steps

‒ Transitions

‒ Actions

Sequence Control Program (Cont.)

PLC Applications in Automations

- 36.

36 I Copyright© 2024 TPS. All rights reserved

A step is a stage in the control process. For

example, the mixing application has three steps—

the initial step, the mixing step, and the emptying

step. When the control program receives an input, it

will execute each of these steps starting with step 1.

Each step may or may not have an action associated

with it. An action is a set of control instructions

prompting the PLC to execute a certain control

function during that step. An action may be

programmed using any one of the four IEC 1131-3

languages.

PLC Applications in Automations

Sequence Control Program (Cont.)

- 37.

- 38.

38 I Copyright© 2024 TPS. All rights reserved

Lessons In Industrial Instrumentation Rev1.2by

Tony R. Kuphaldt

Programmable Controllers Second Edition by L. A.

Bryan E. A. Bryan

Practical SCADA for industry. By David Bailey &

Edwin Wright

Automation systems and PLCs. By Hugh Jack

Fundamentals of PLCs. By Phil Melore

Principles of User Interface Design. Article by Niall

Murphy

References

- 39.

39 I Copyright© 2024 TPS. All rights reserved

SCADA System Security. Article By Abhishek

Bhattacharjee, Stephen Flannigan and Jens

Nasholm, Citect Inc.

Alarm code in PLCs. Article by Allen Nelson,

PLCs.net

InTouch® Reference Guide. By Invensys Systems,

Inc.

Ethernet Communications Modules. By Automation

Direct, Inc.

Fundamentals of Control 2006 by PAControl.com

References