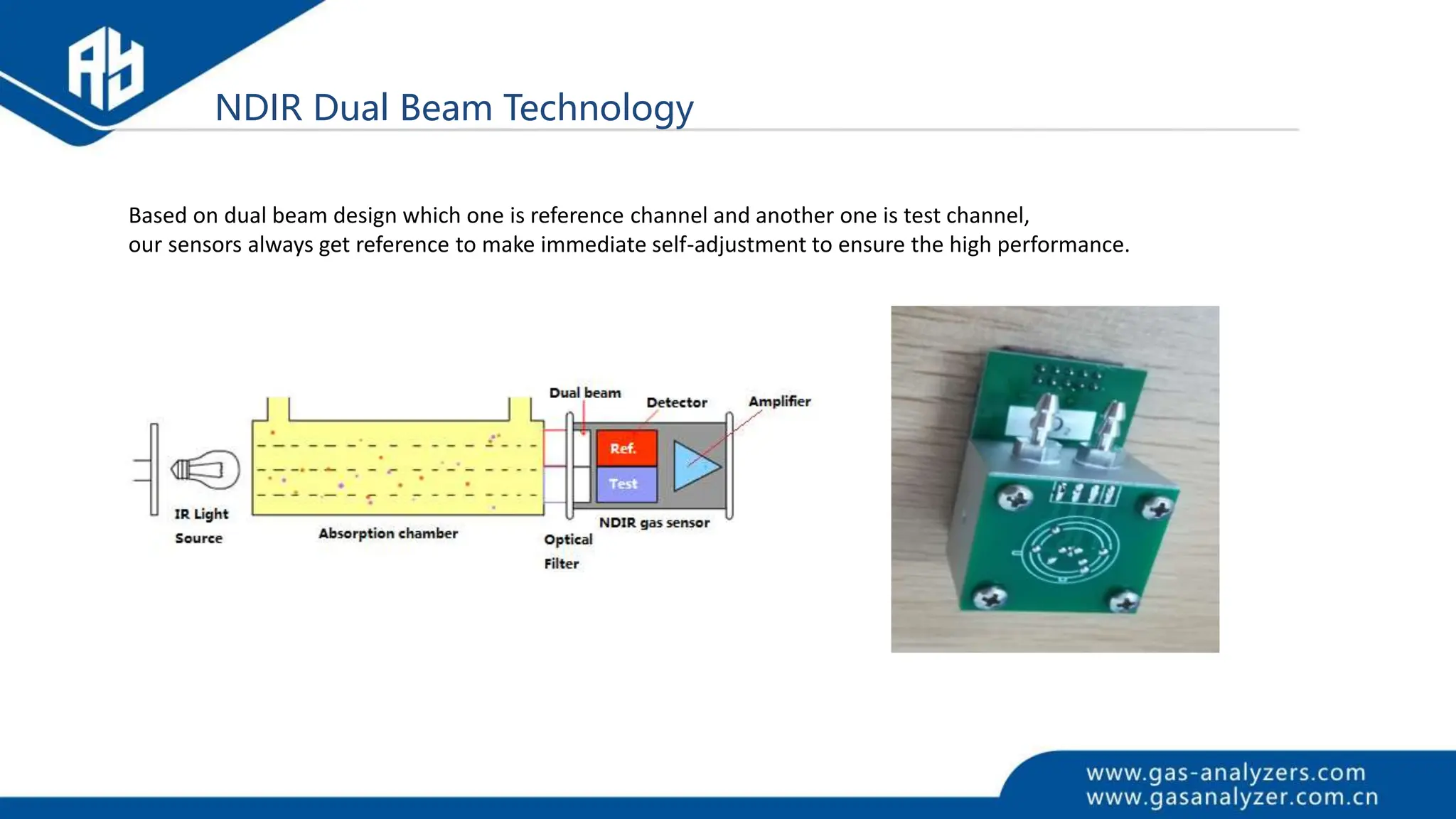

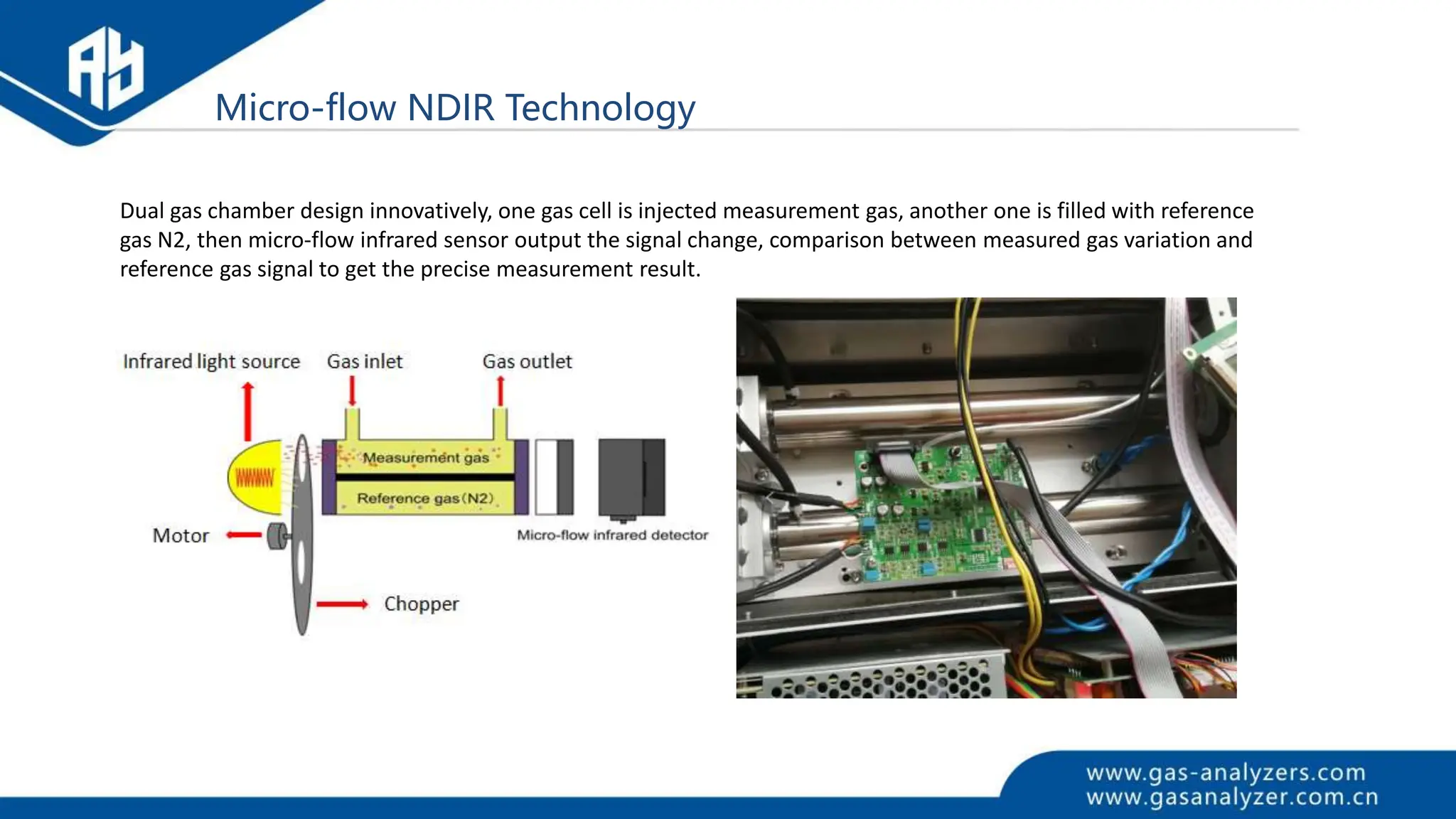

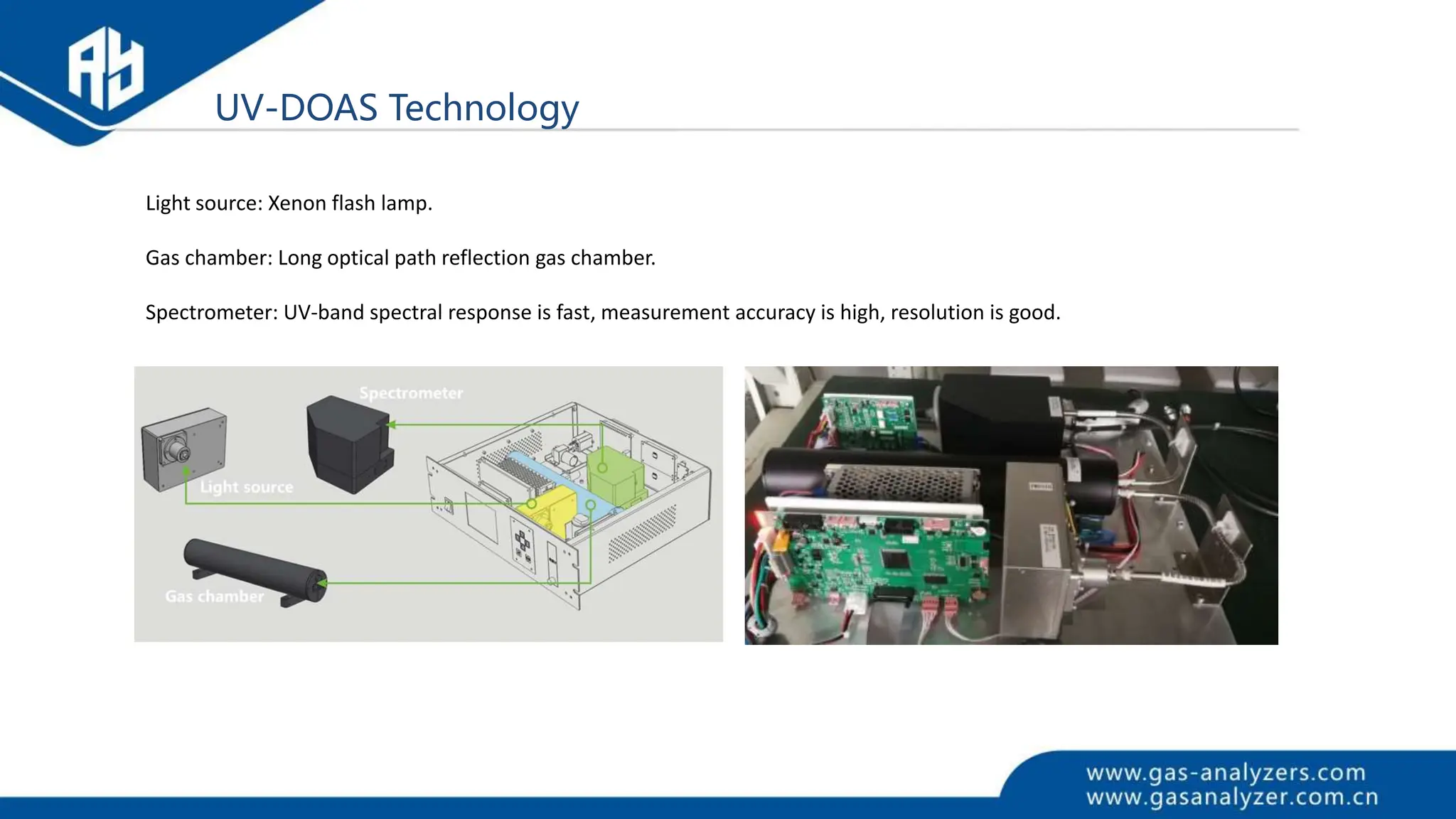

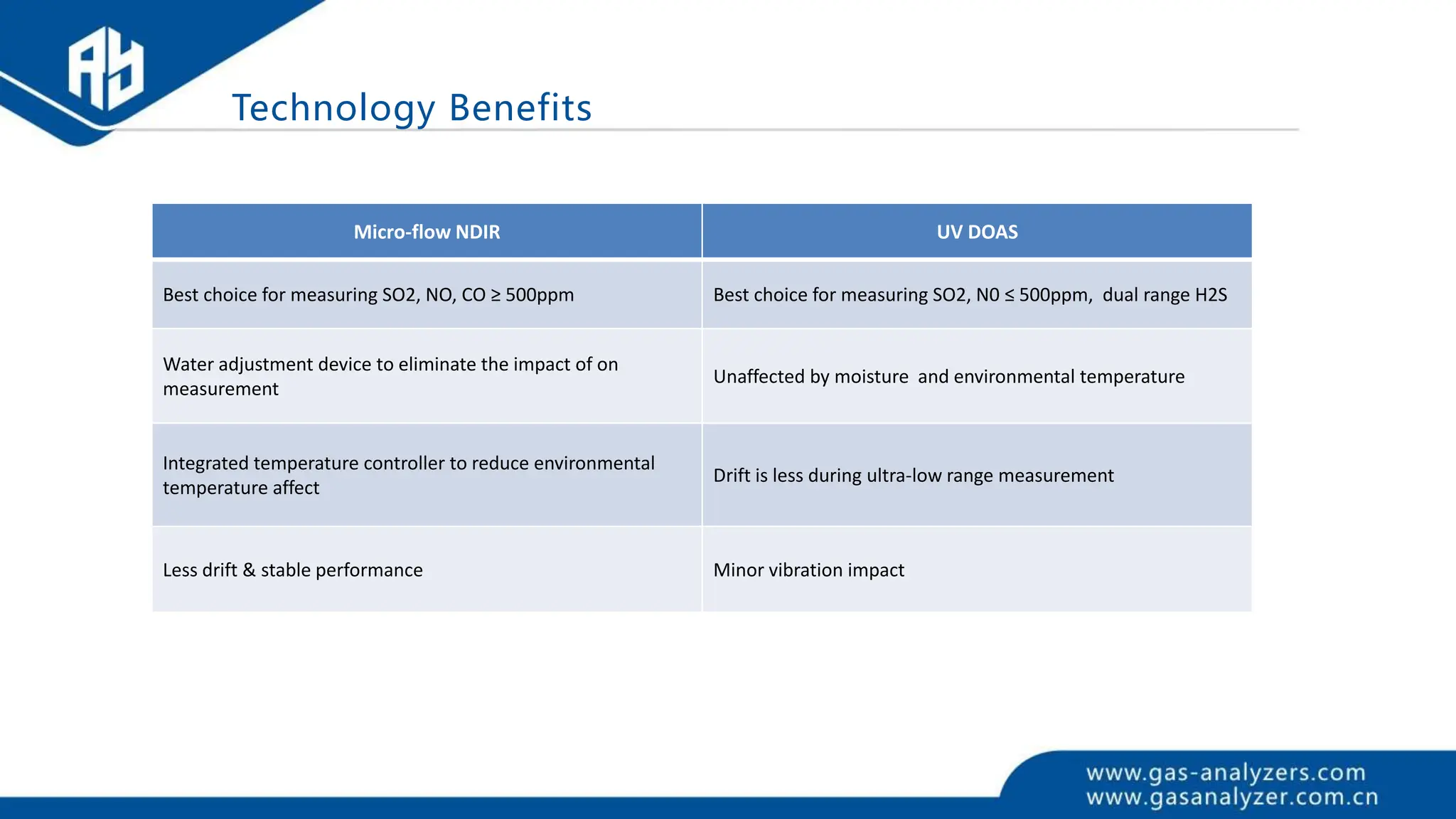

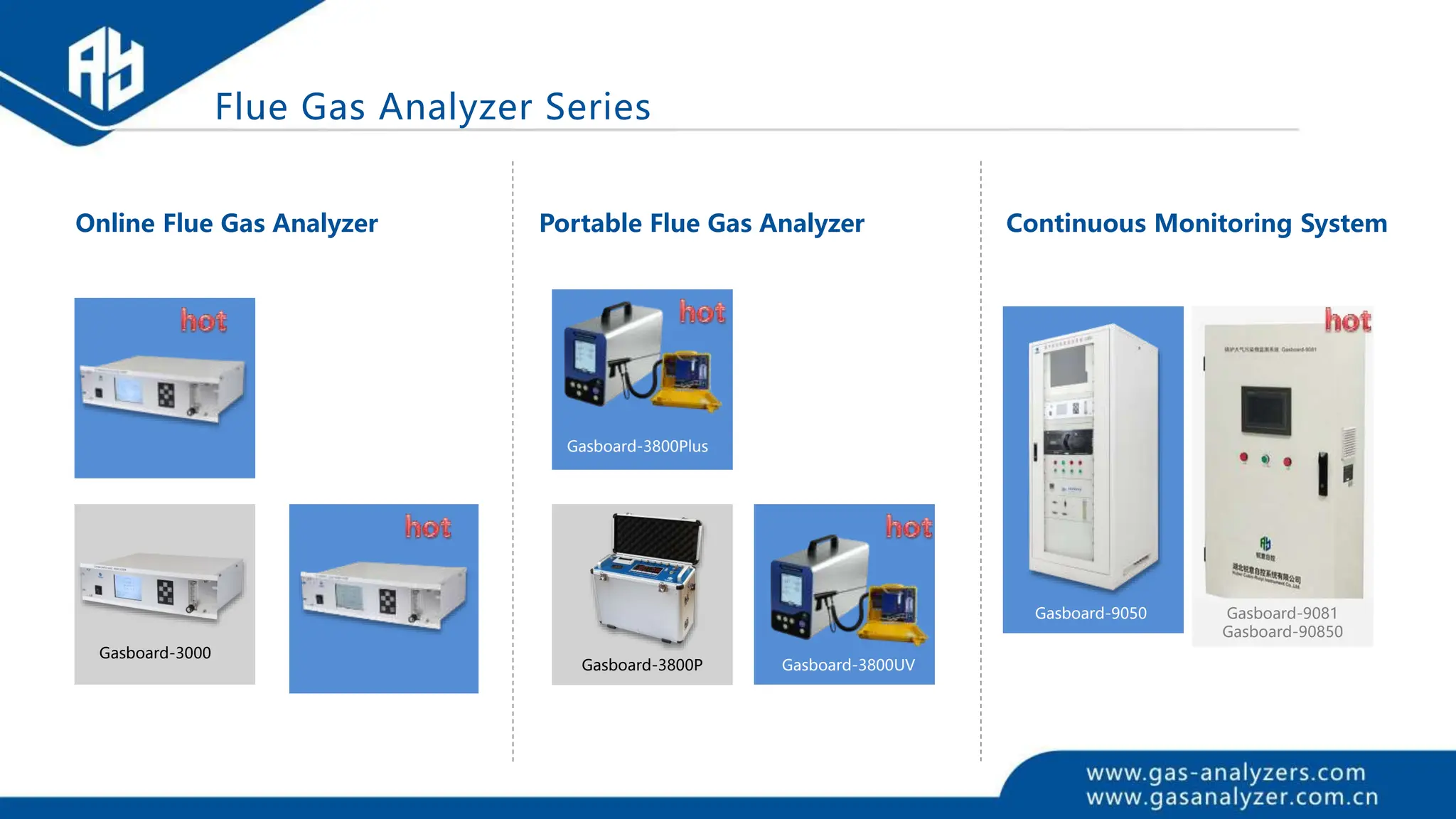

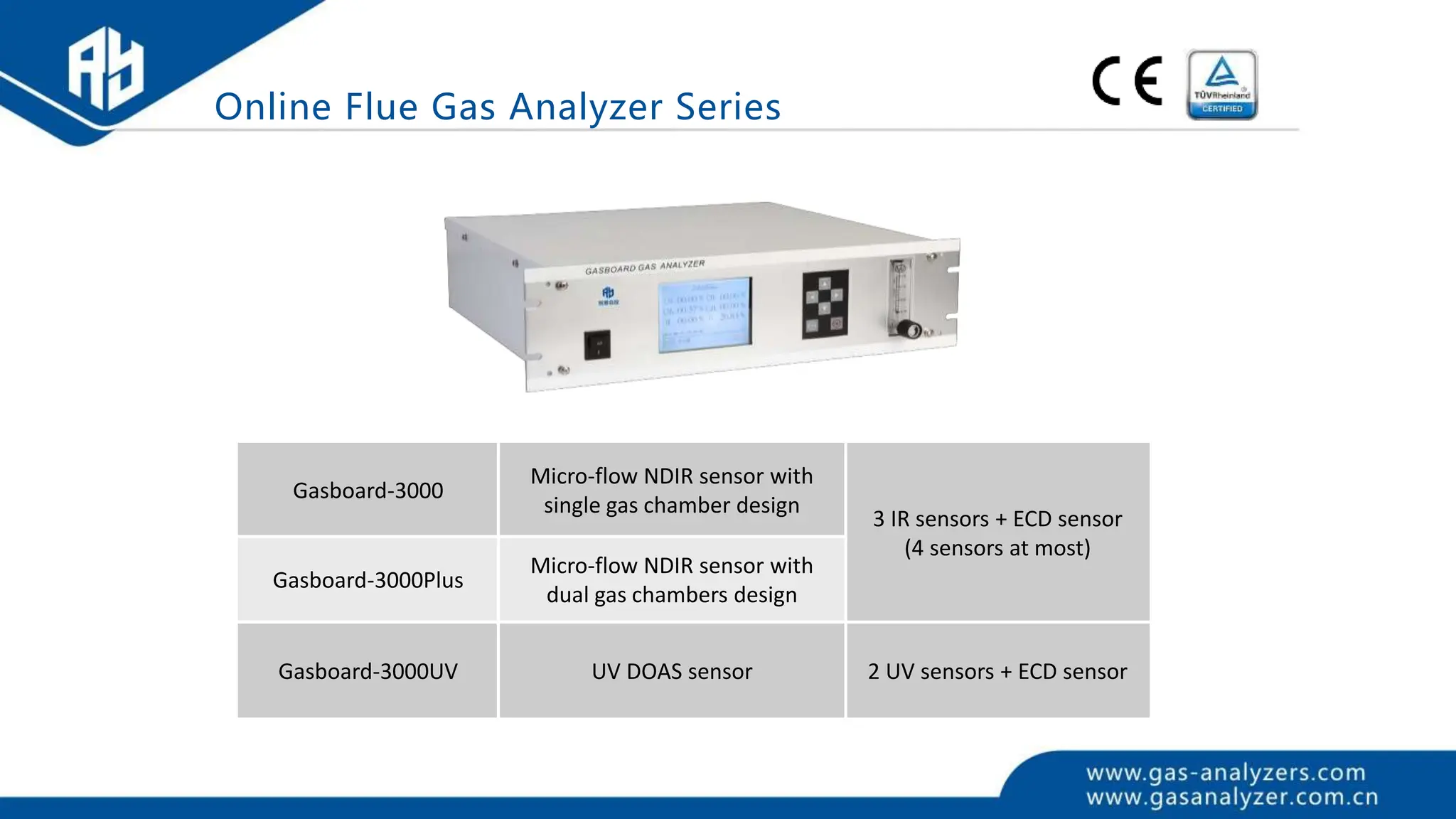

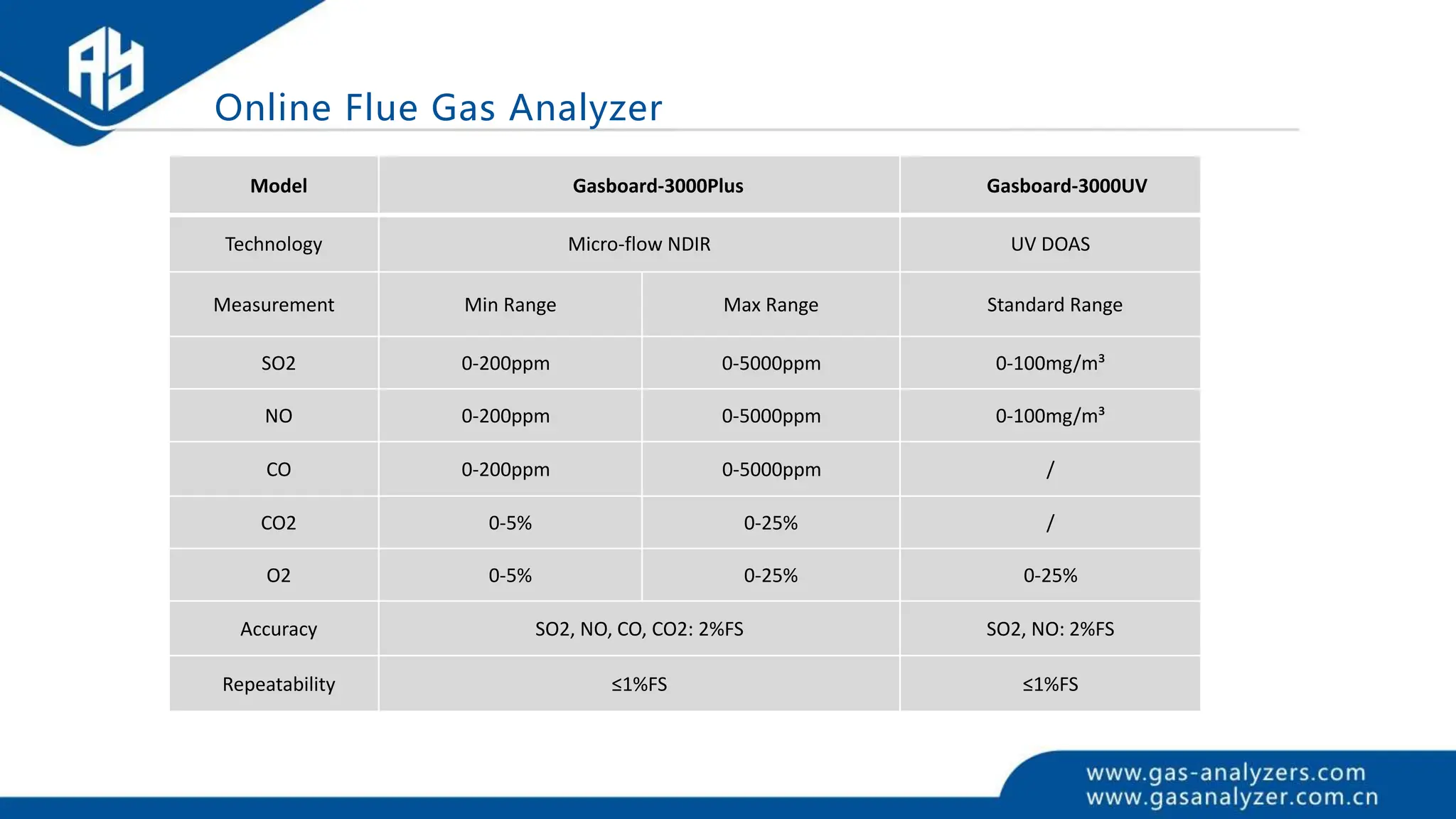

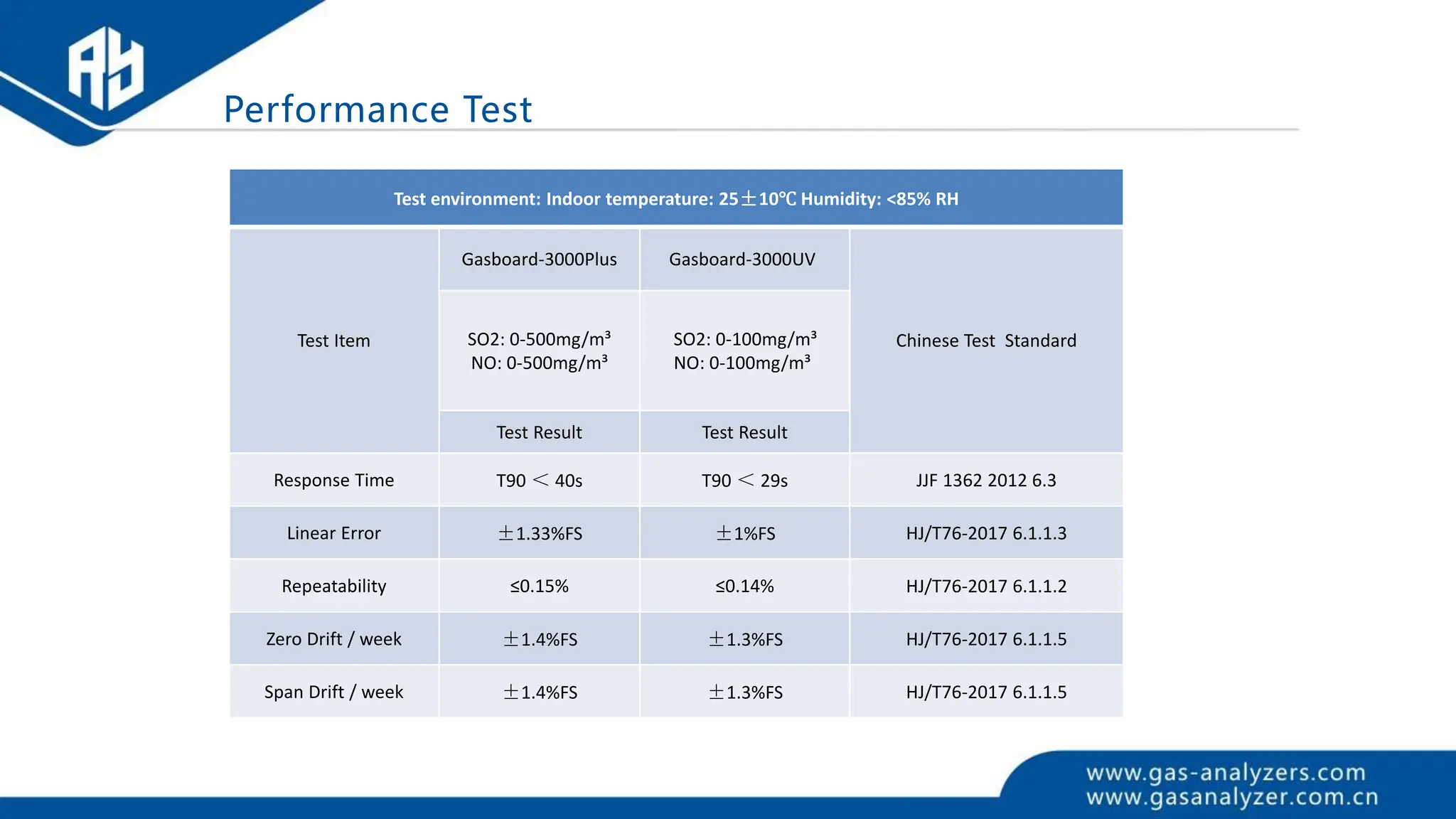

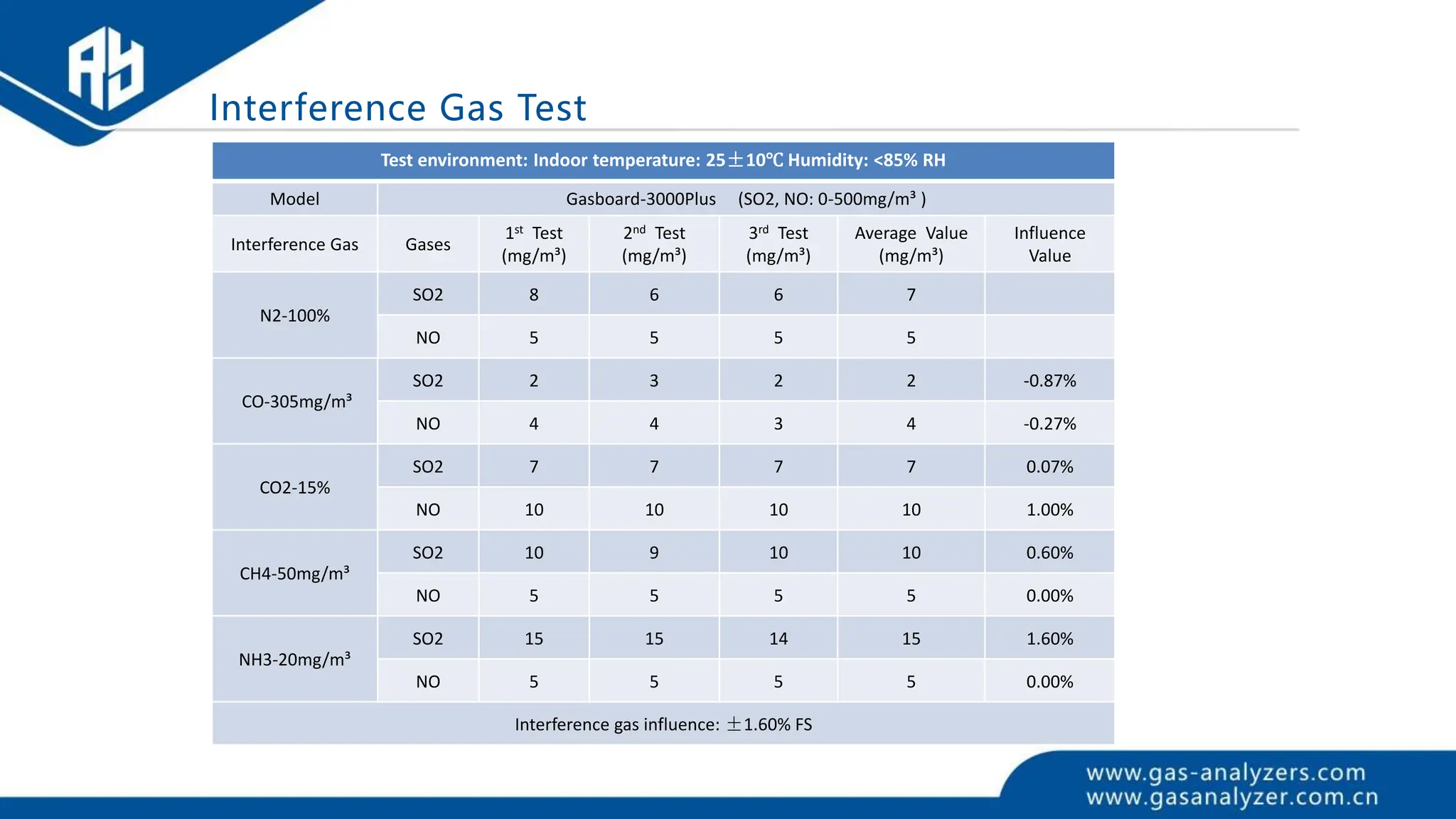

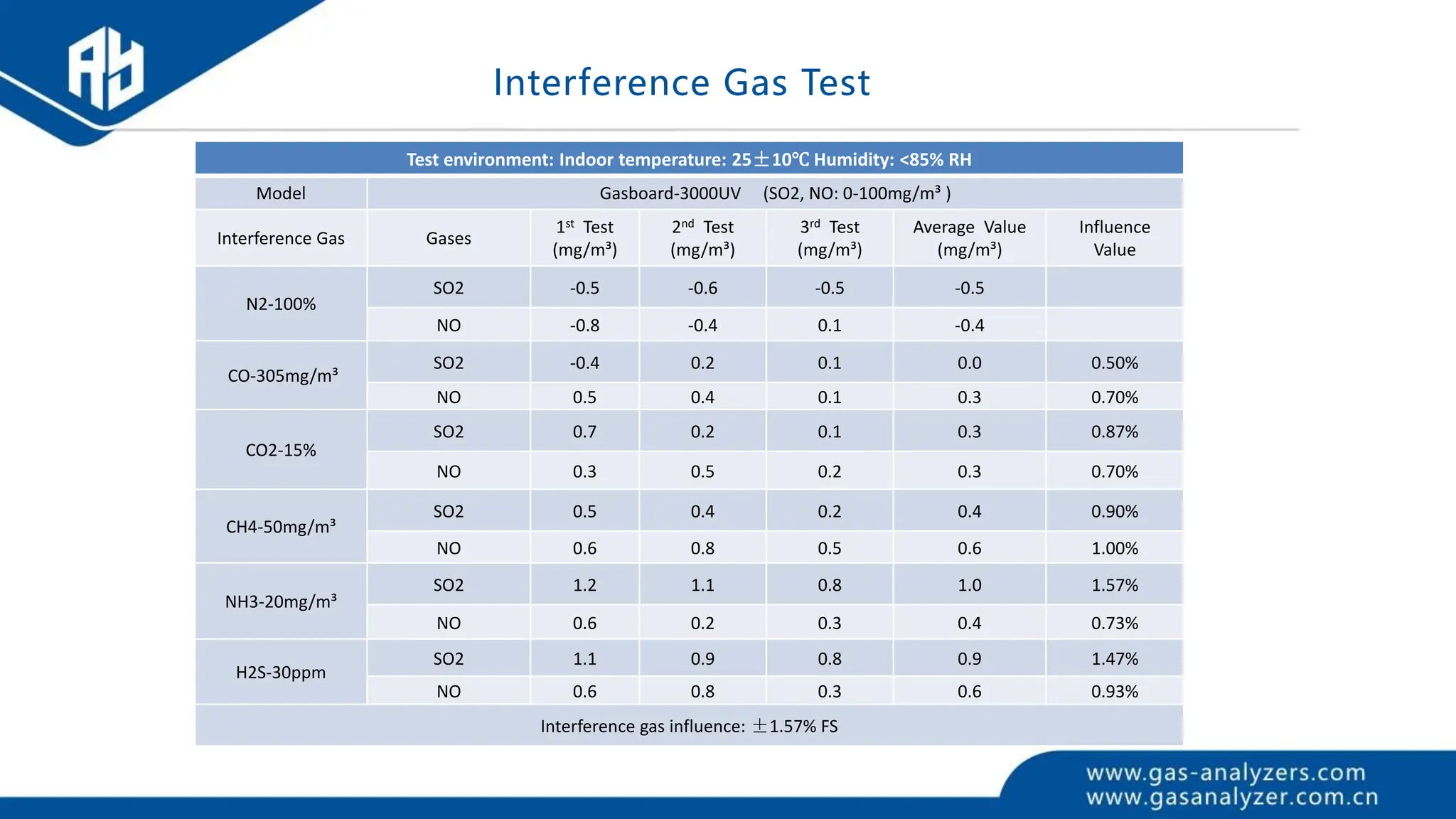

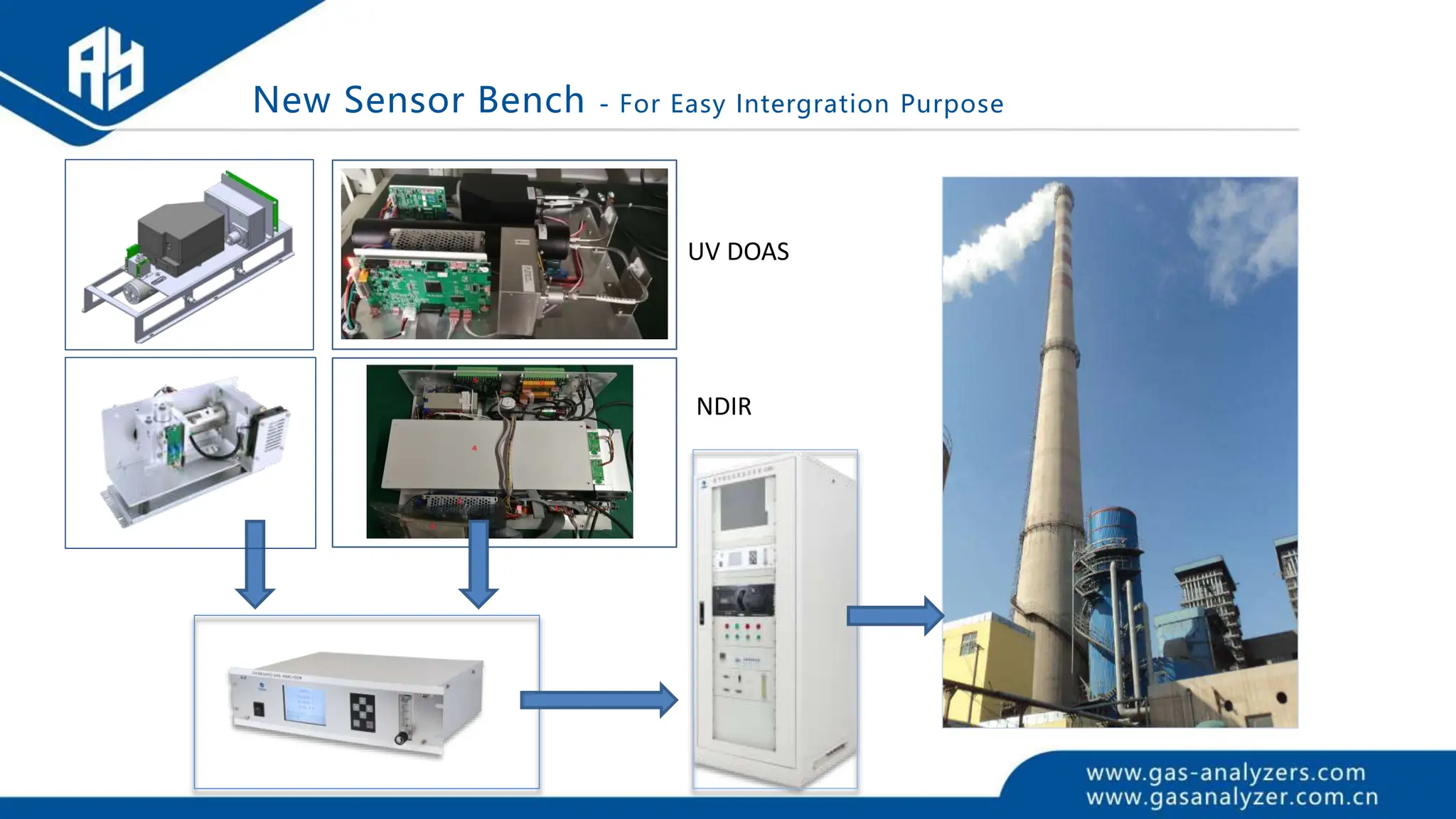

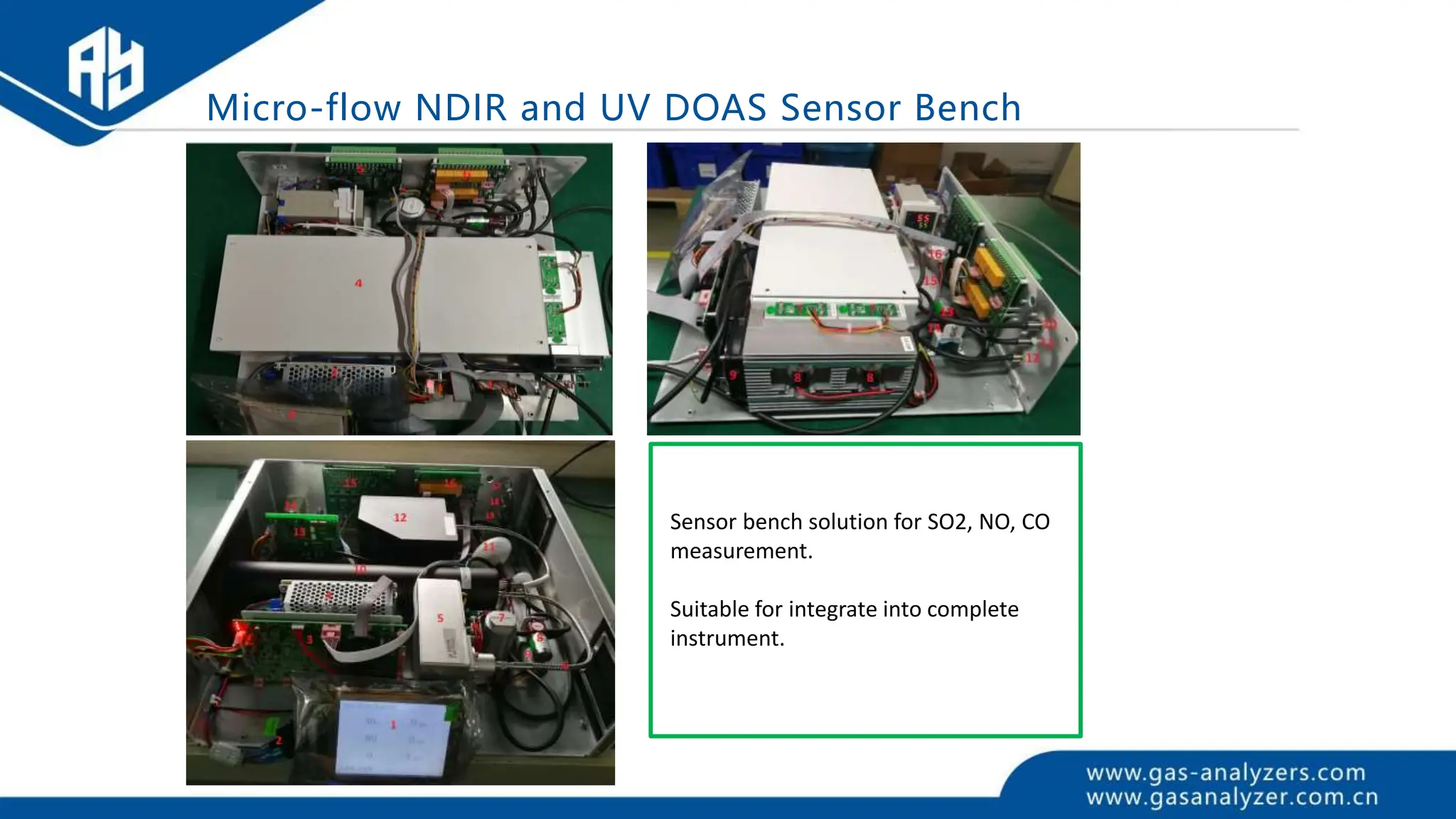

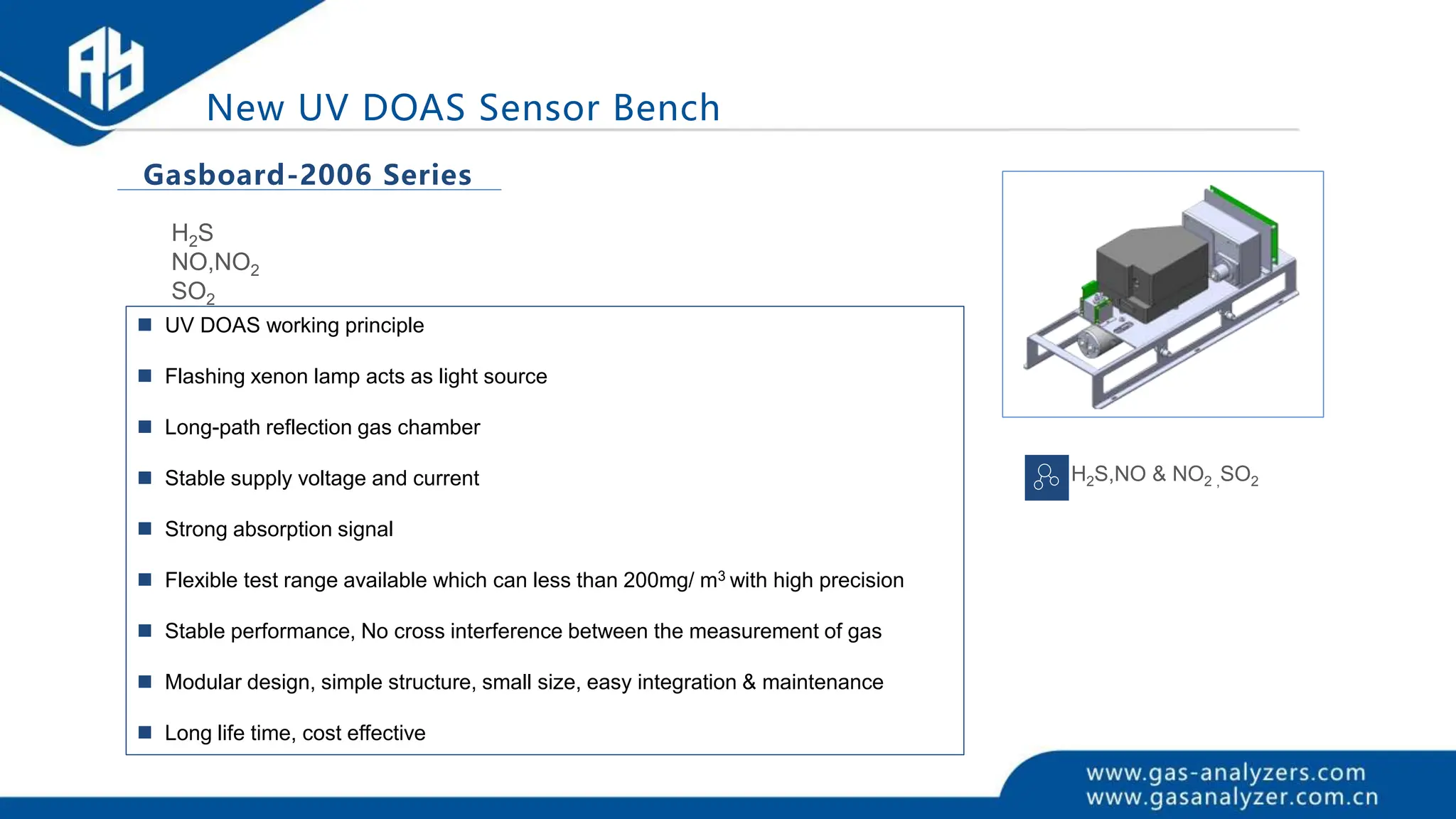

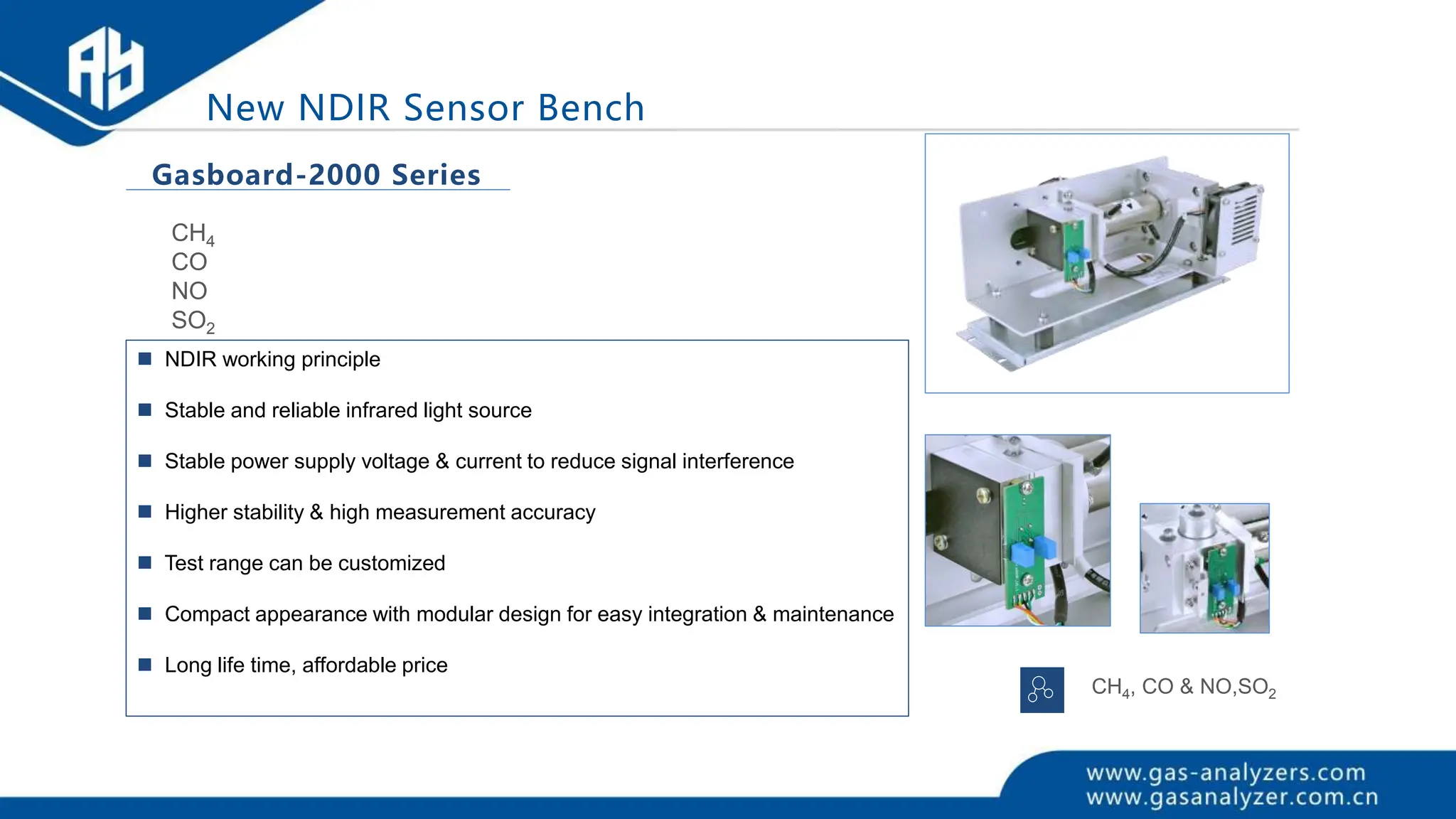

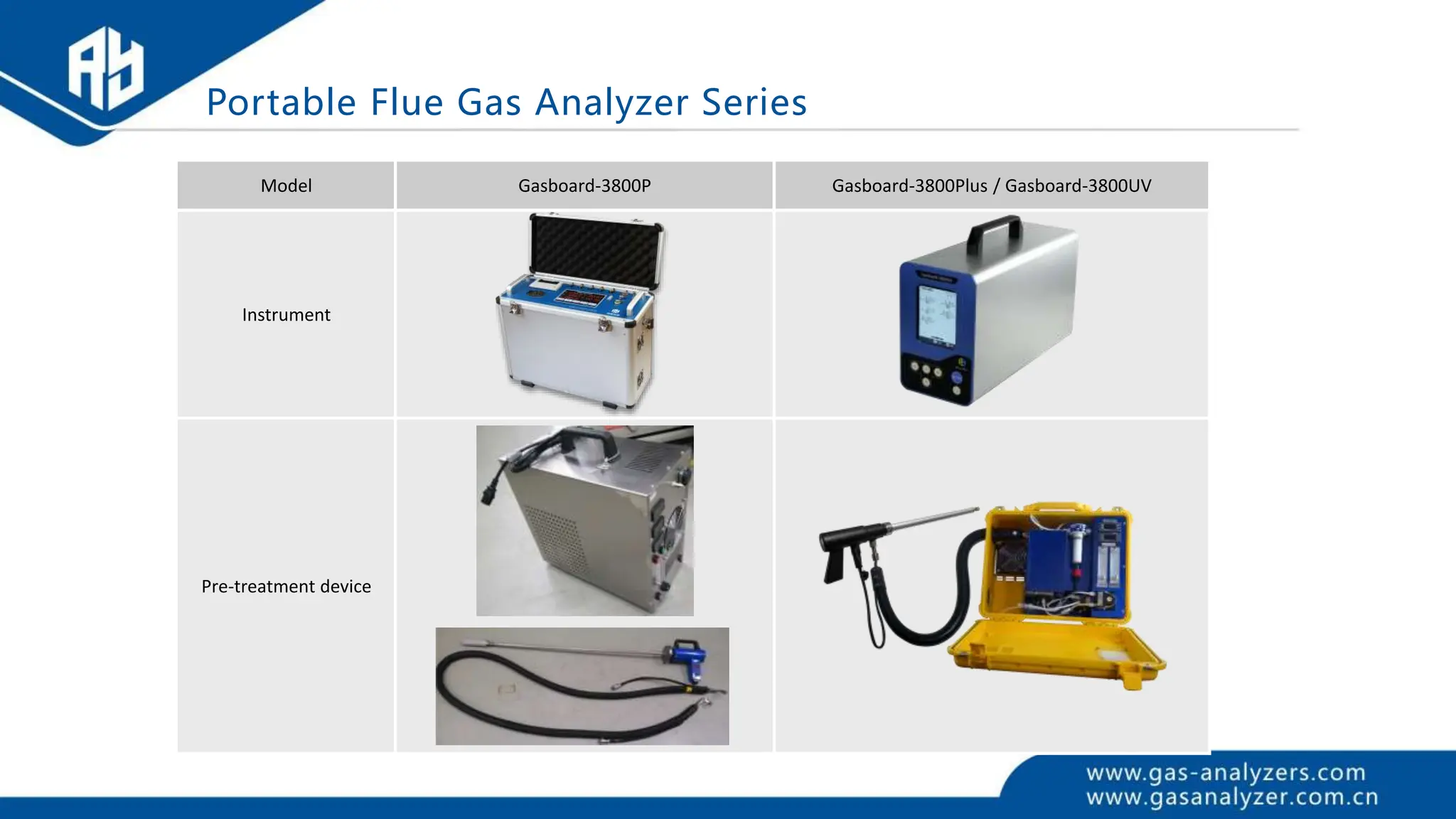

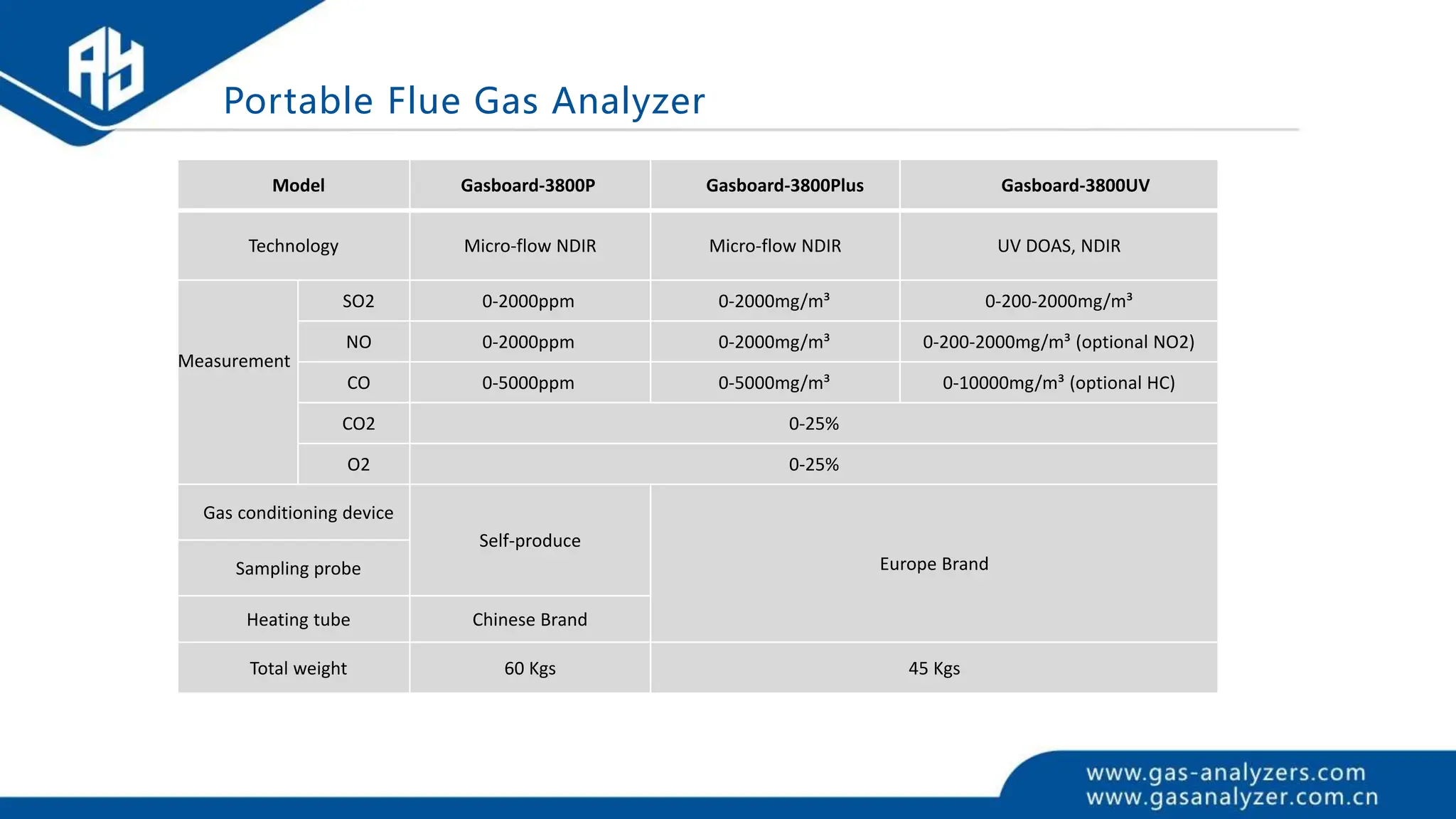

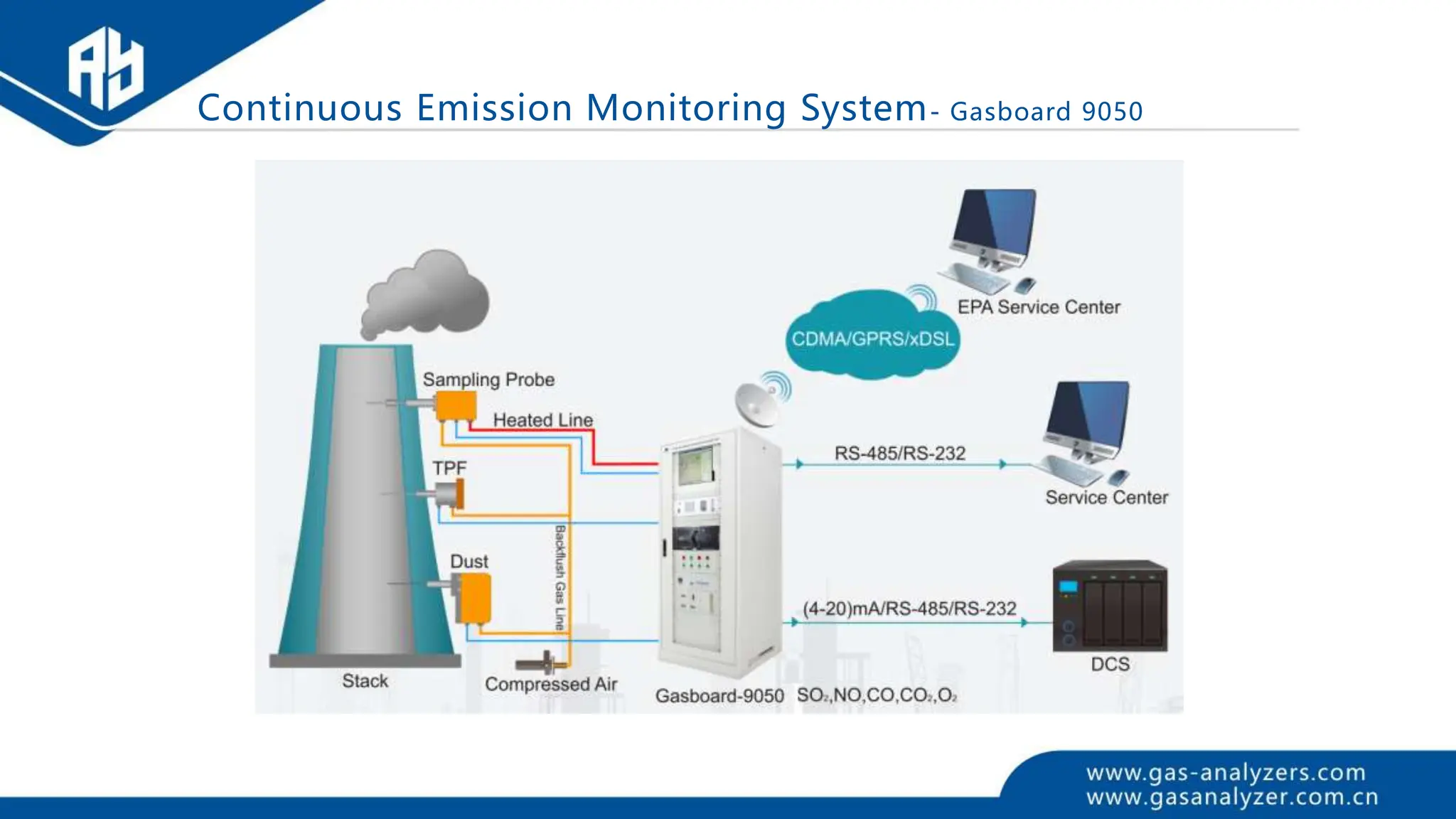

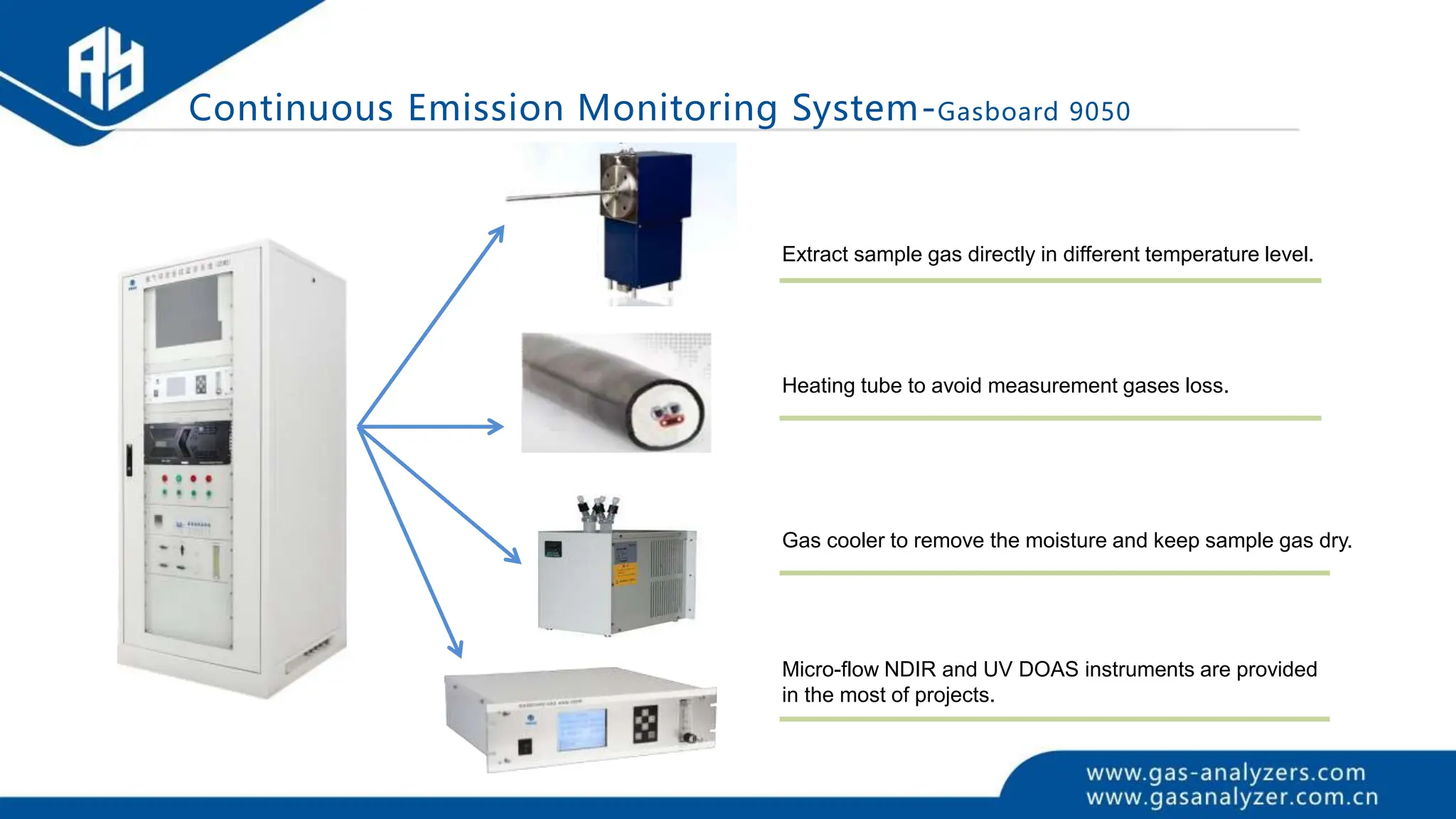

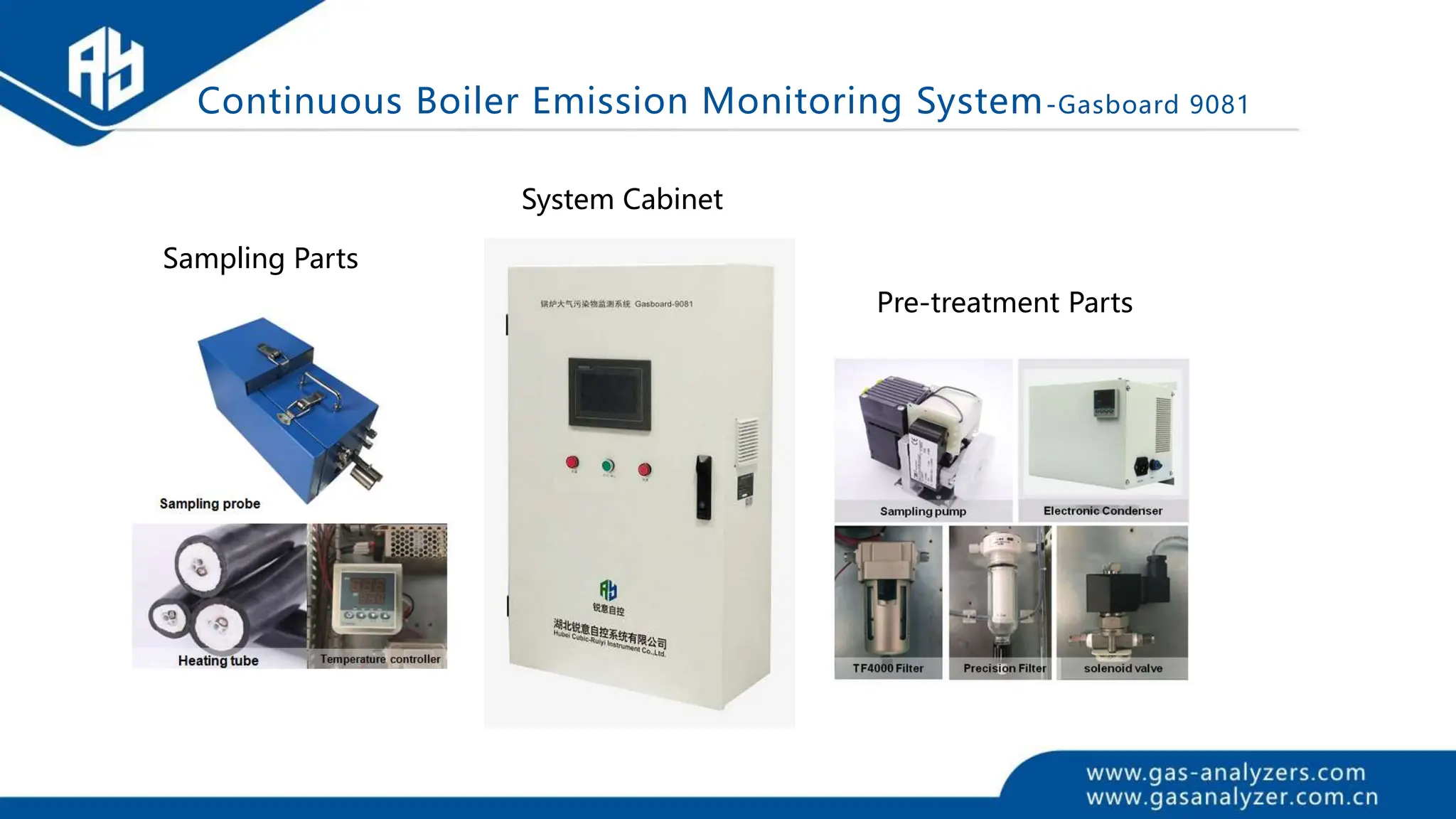

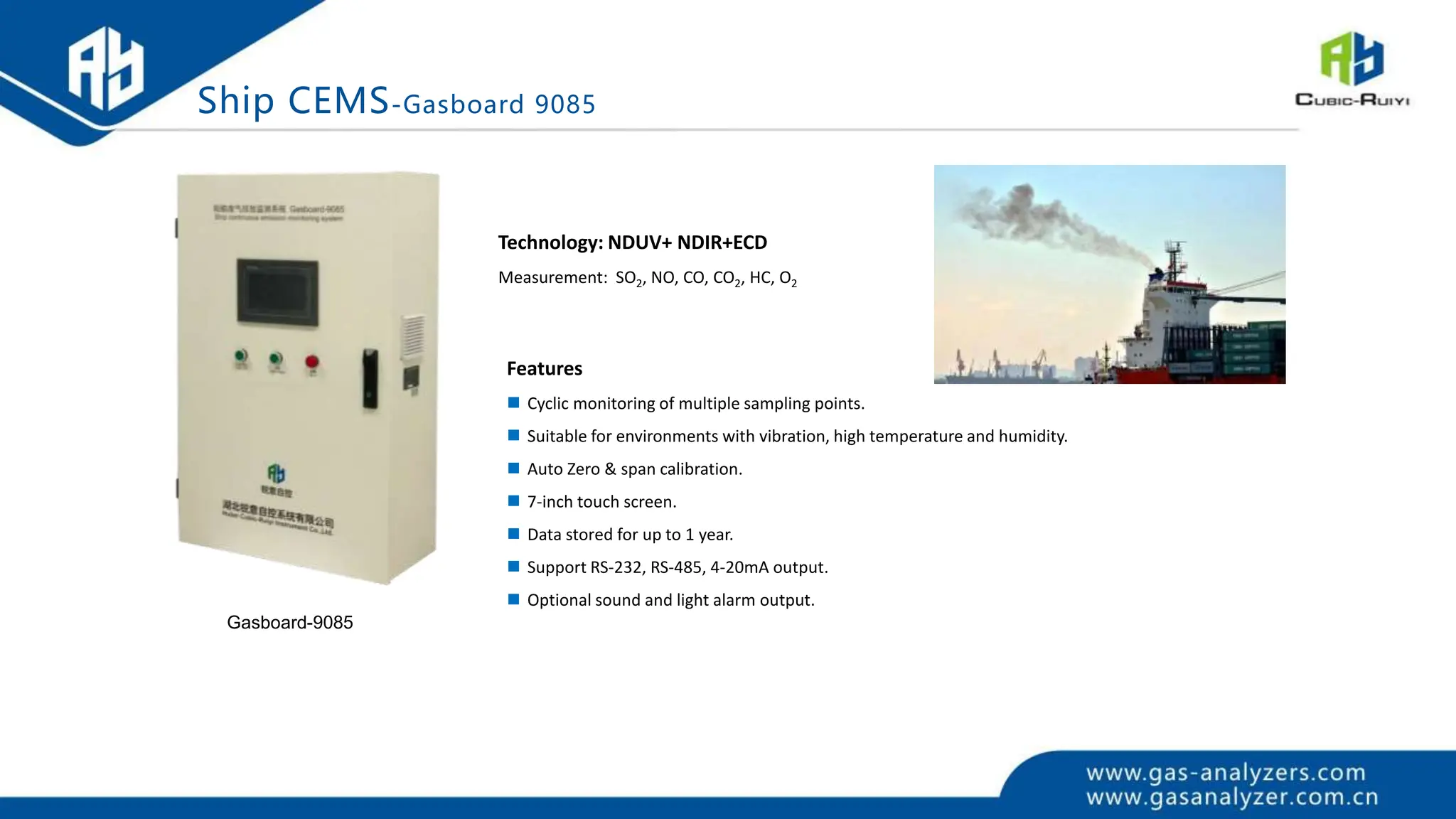

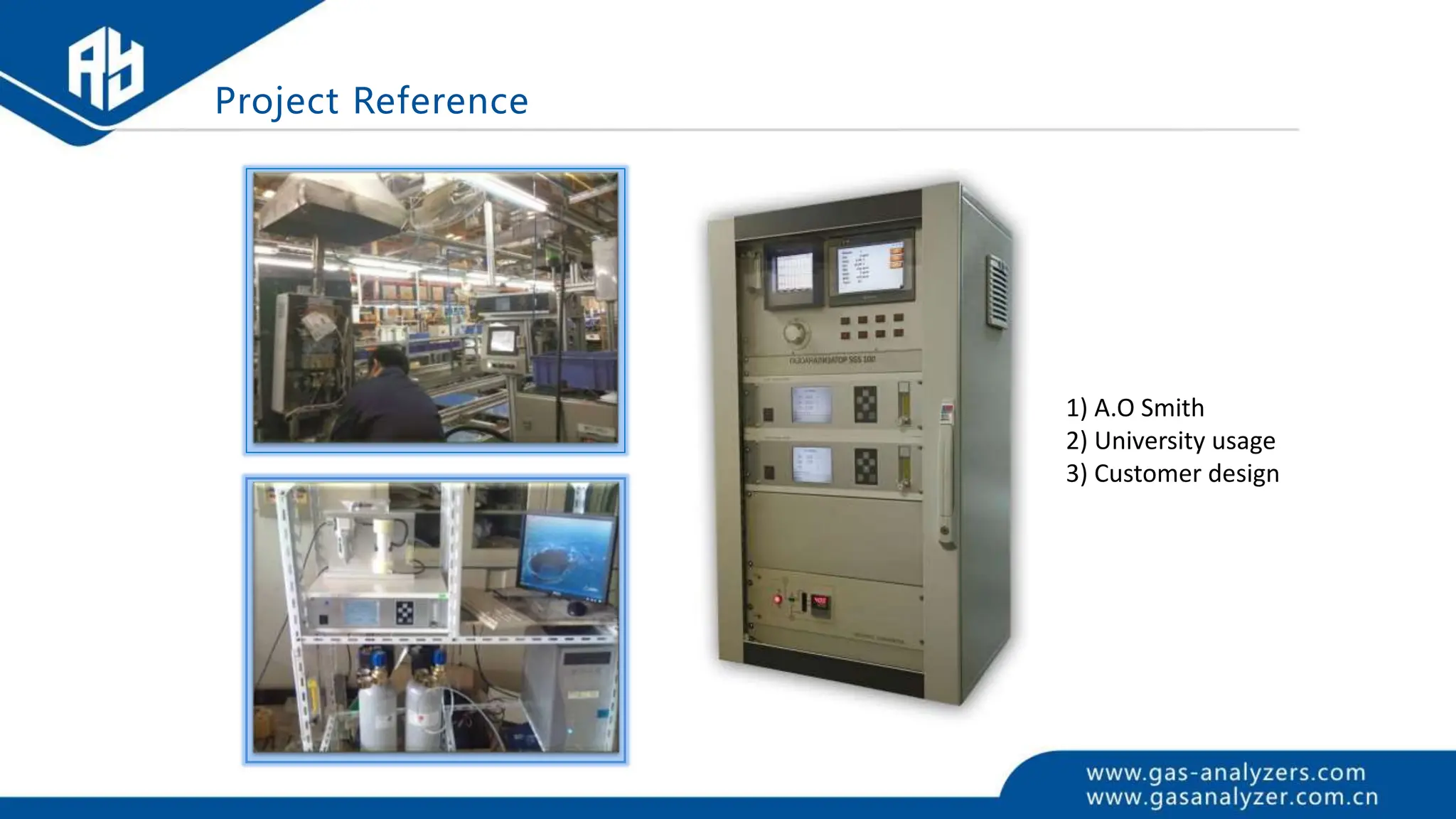

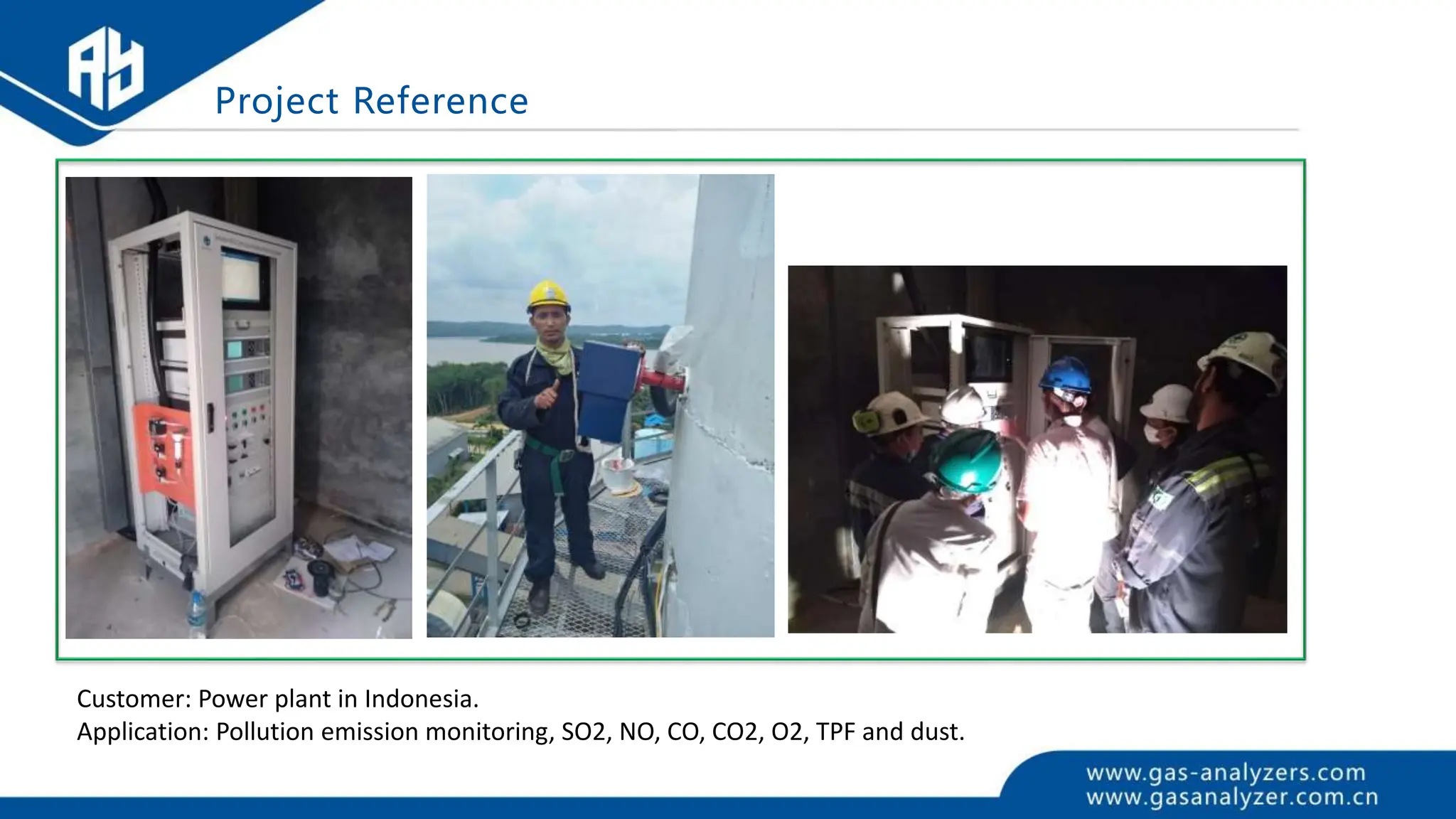

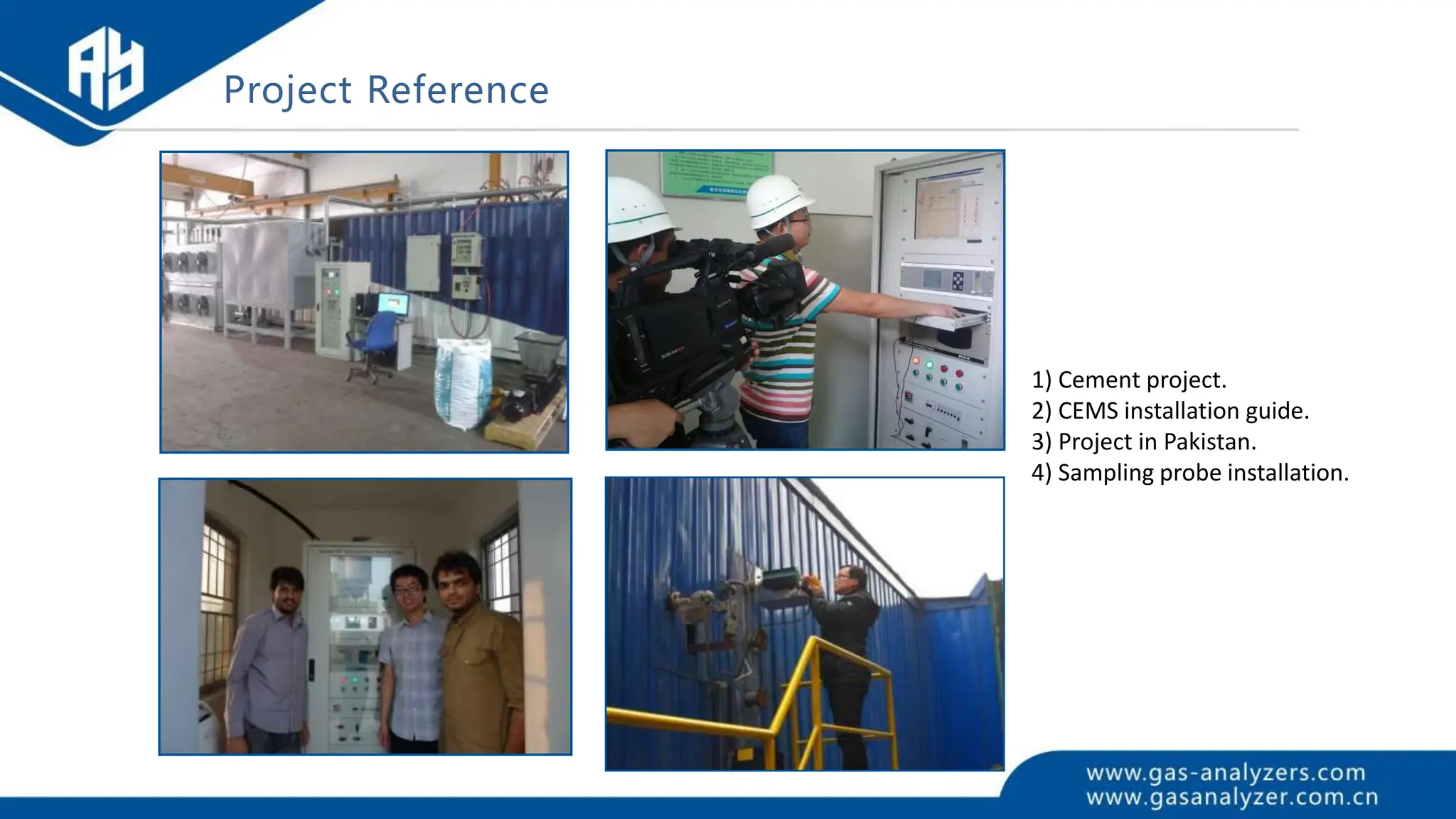

The document describes advanced flue gas analyzer technologies, including NDIR dual beam and UV-DOAS technologies, highlighting their precise measurement capabilities for various gases such as SO2, NO, and CO. It details multiple models of gas analyzers, their performance specifications, and testing results that demonstrate stability, accuracy, and minimal drift in readings. Additionally, the document provides information about applications in pollution monitoring within different industrial contexts.