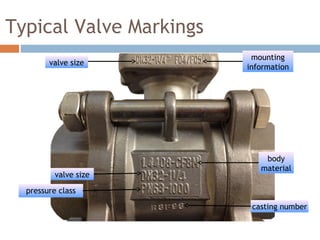

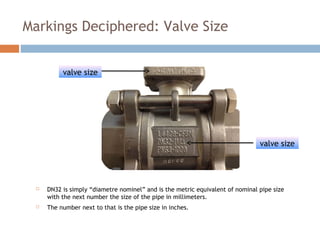

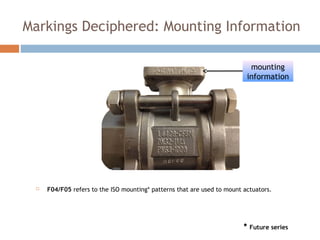

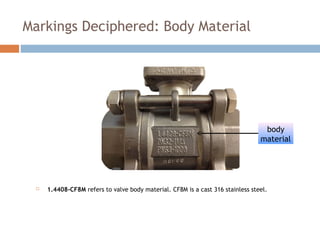

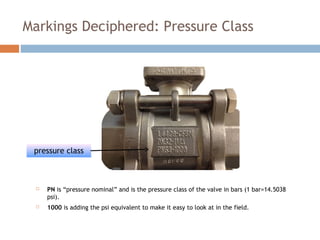

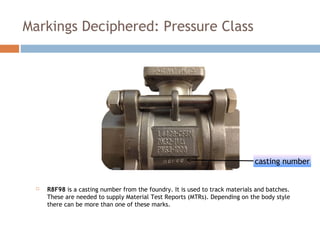

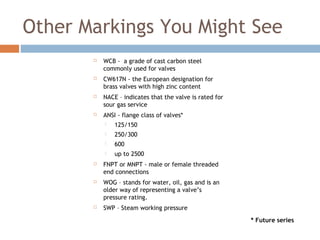

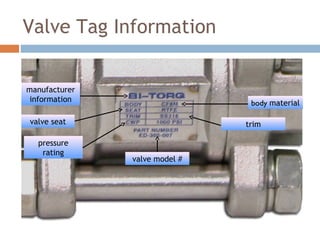

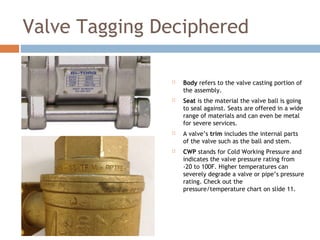

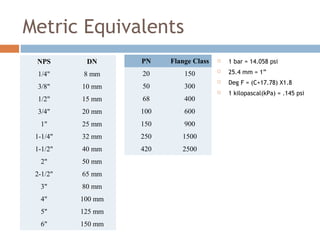

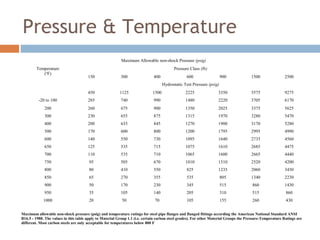

This document provides information to help identify valves, including typical markings found on ball valves. It discusses markings that indicate valve size, body material, pressure class, and casting number. It also explains how to decipher valve tag information regarding the body material, seat material, pressure rating, and trim. Additionally, it provides metric equivalents for size references and a chart showing maximum allowable pressure at different temperatures. The goal is to equip readers to identify key details about valves to determine appropriate replacements or retrofits.