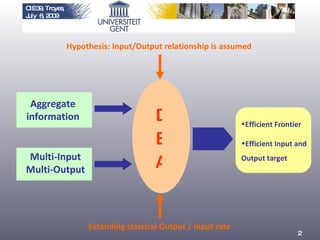

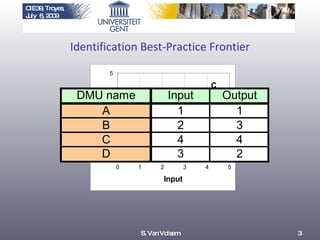

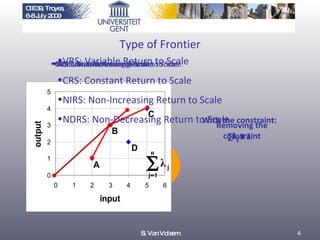

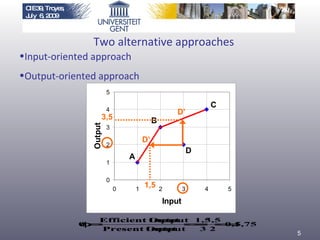

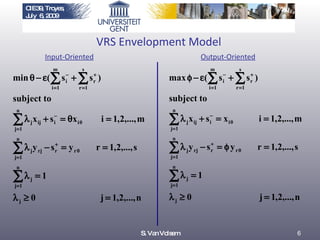

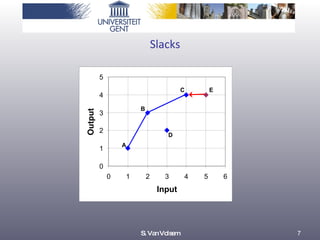

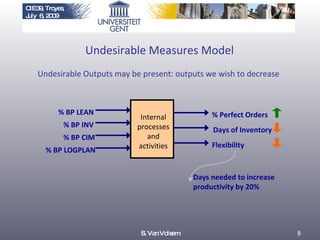

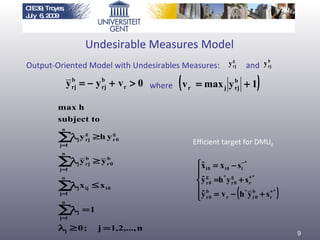

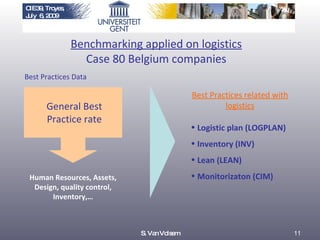

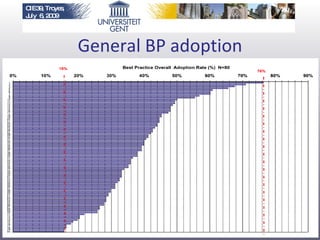

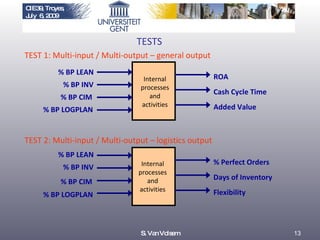

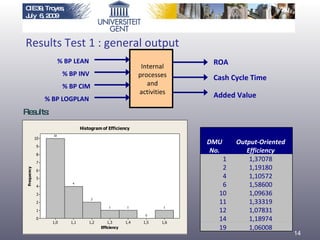

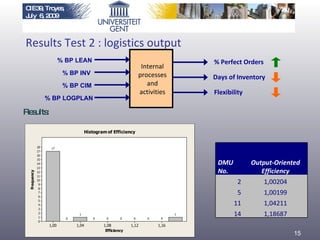

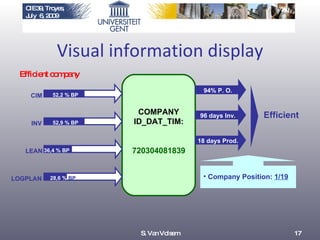

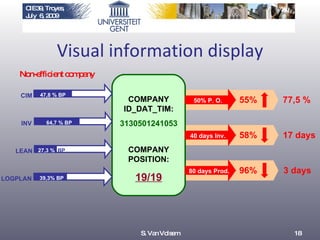

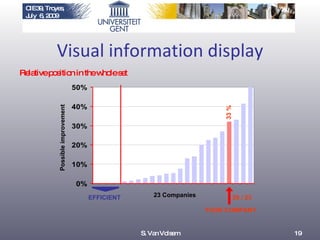

The document discusses using data envelopment analysis (DEA) to benchmark logistics performance in Belgian manufacturing companies. DEA is used to identify efficient companies and output targets by establishing an efficient frontier. Two tests were conducted using different input and output variables to benchmark companies' general performance and logistics performance. The results identified the relative efficiency of companies and potential areas for improvement. Visual information can also be provided to companies to benchmark their performance against peers.