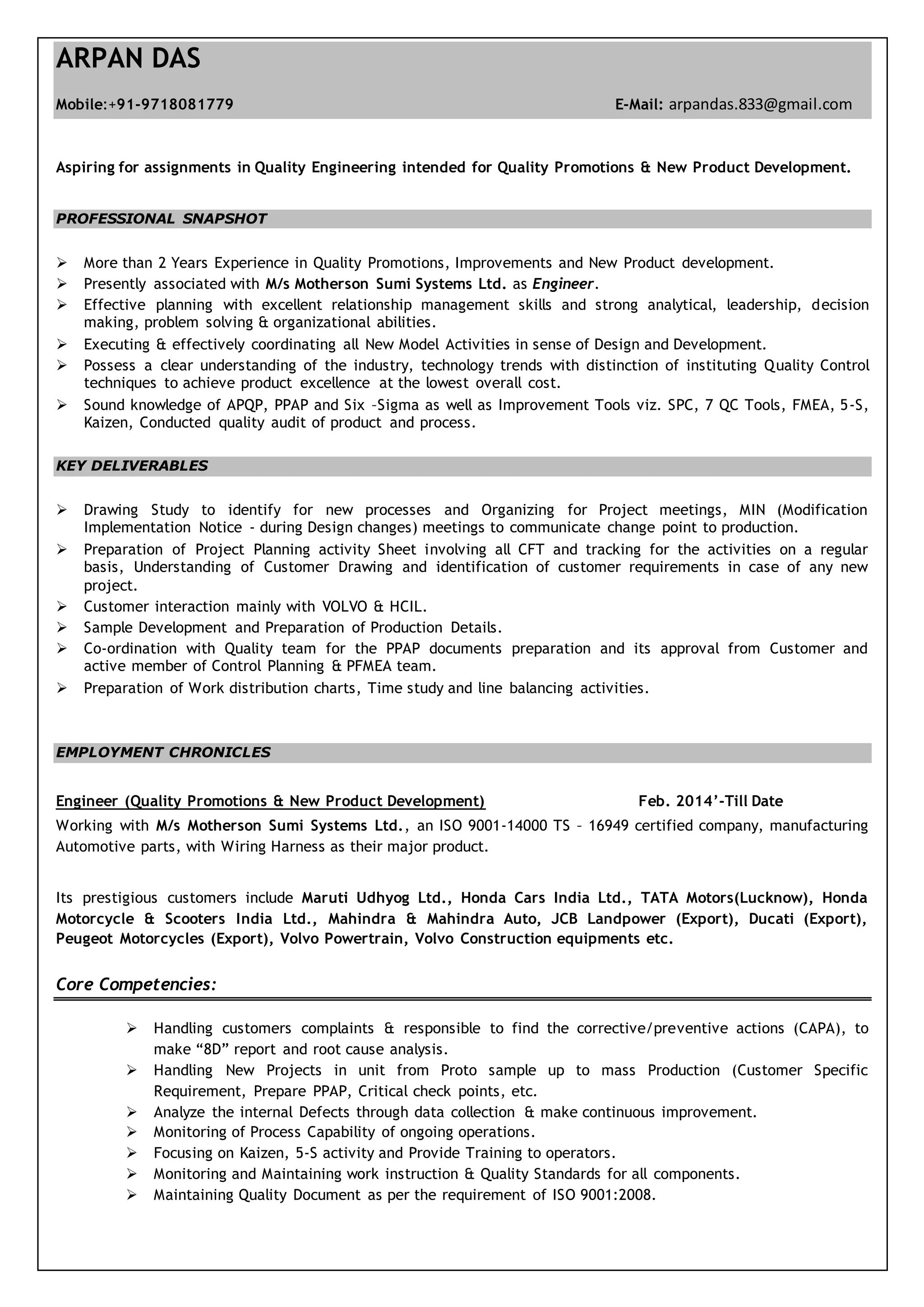

Arpan Das is seeking opportunities in quality engineering for quality promotion and new product development. He has over 2 years of experience in quality improvement and new product development at Motherson Sumi Systems Ltd. where he executes new model activities related to design and development. His responsibilities include drawing studies, project planning, sample development, coordination of PPAP documentation, and preparation of work distribution charts. He is proficient in quality tools like APQP, PPAP, Six Sigma, SPC, FMEA and has a technical education with a B.Tech in Mechanical Engineering.