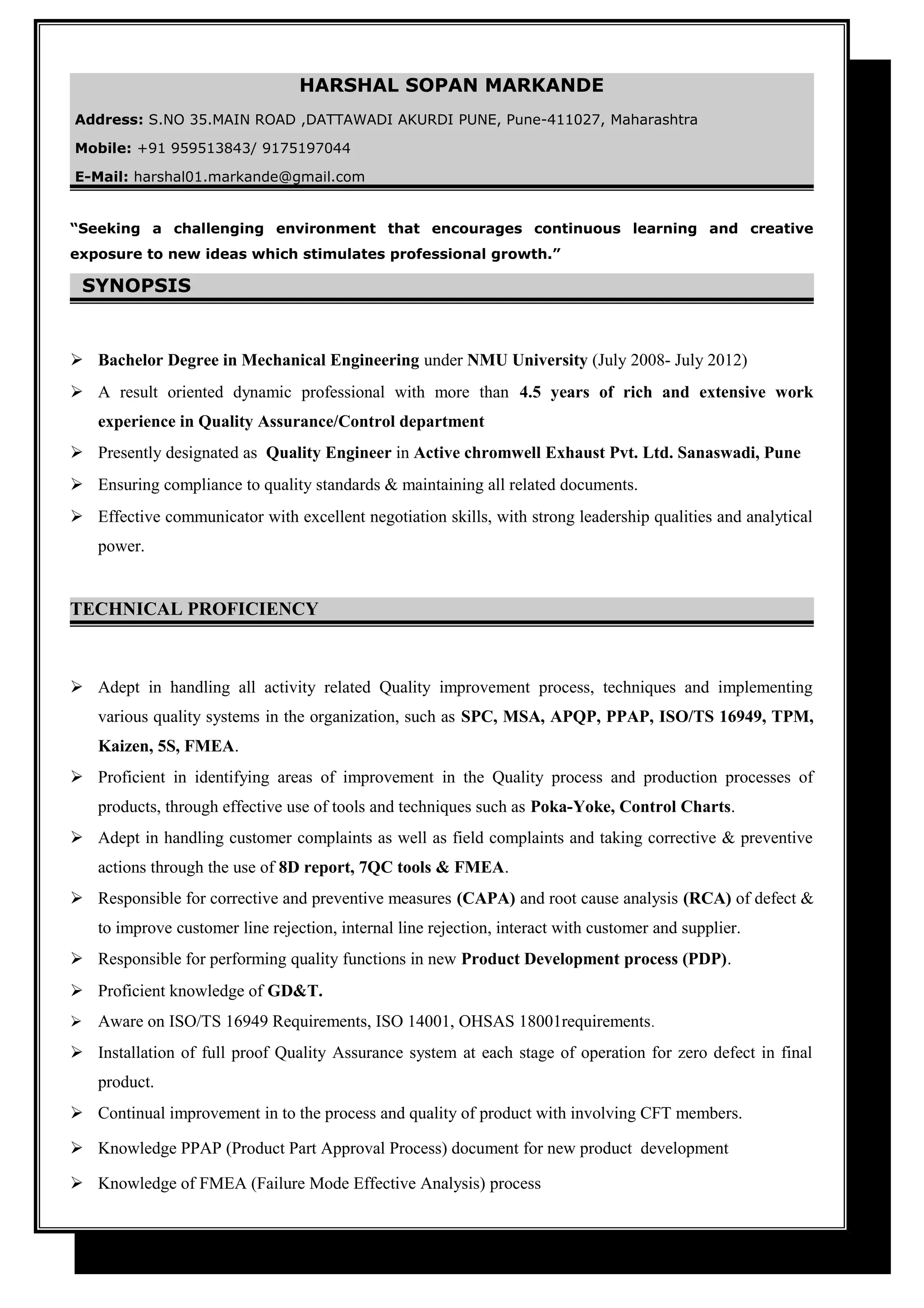

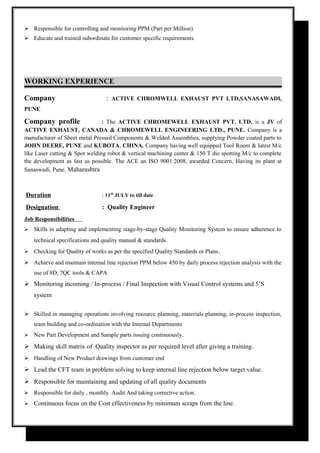

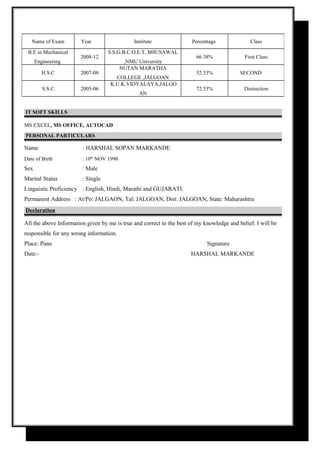

This document contains a resume for Harshal Sopan Markande. It summarizes his educational qualifications including a Bachelor's Degree in Mechanical Engineering. It also outlines his over 4 years of work experience as a Quality Engineer and Junior Engineer, with responsibilities like quality assurance, implementing quality systems, handling customer complaints and ensuring compliance. His technical skills include knowledge of quality tools, ISO standards, and systems like APQP.