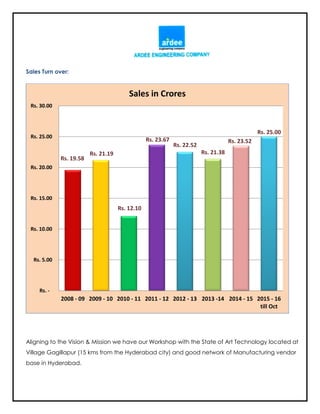

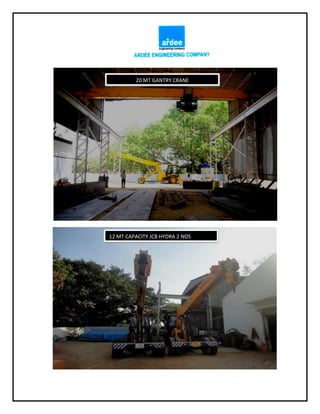

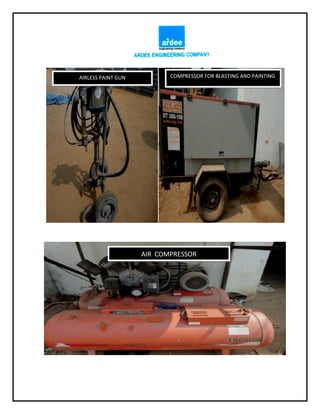

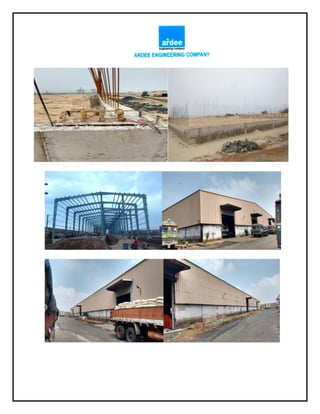

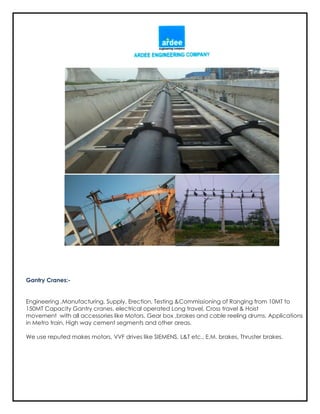

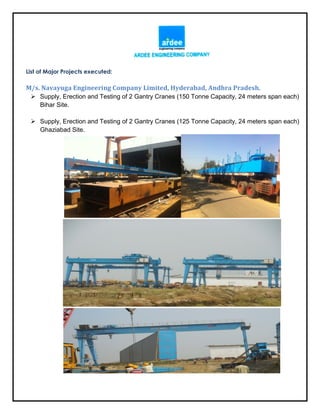

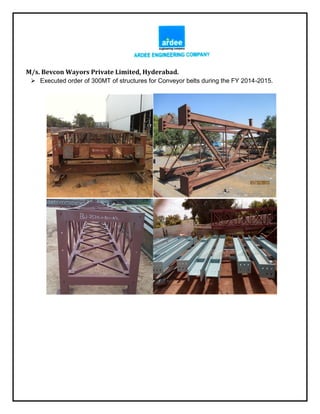

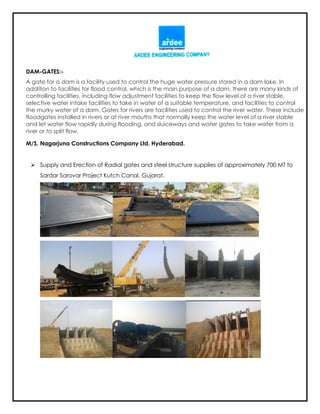

Ardee Engineering Company, established in 2008, specializes in turnkey electro-mechanical and civil solutions in sectors like ports, power, and manufacturing. The company aims for operational excellence through a dedicated professional team and has executed numerous major projects, including pre-engineered buildings and gantry cranes. With a workshop in Hyderabad and advanced machinery, they maintain high standards in quality and customer satisfaction, backed by a management team with extensive industry experience.