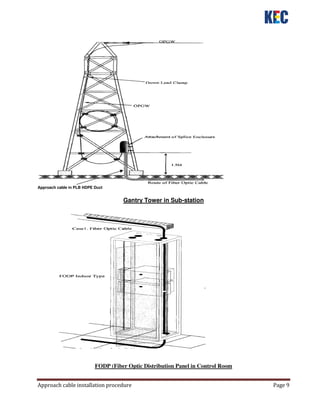

The document provides guidelines for installing approach cables that connect overhead fiber optic cables on transmission towers to indoor fiber optic distribution panels. It describes the structure of approach cables and outlines procedures for installing them in HDPE ducts, including pulling cables through ducts carefully to avoid twisting or exceeding minimum bend radii. Connectors should be cleaned and protected before testing to ensure reliable operation and prevent contamination.