The document summarizes an artificial bee colony algorithm seminar that covered:

1) An introduction to artificial bee colony algorithms and how they are nature-inspired optimization techniques.

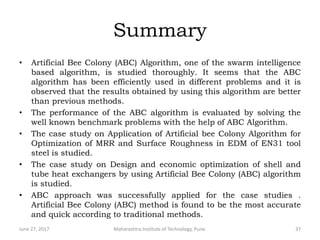

2) Applications of artificial bee colony algorithms in various engineering domains like mechanical, electrical, and civil engineering for problems like parameter optimization, structural design, and data mining.

3) Case studies demonstrating the use of artificial bee colony algorithms to optimize benchmark engineering problems like welded beam design, pressure vessel design, and spring design and obtain near-optimal solutions.

![Artificial bee colony algorithm

• The artificial bee colony (ABC) algorithm is a recent

representative of a number of swarm intelligence algorithms

that are inspired by some type of behavior observed in real

bee colonies.[1]

• It was introduced by Karaboga (2005), who applied it to

continuous optimization problems.

• In the ABC algorithm, there are three types of (artificial)

bees, namely employed bees, onlooker bees, and scout

bees.[1]

June 27, 2017 Maharashtra Institute of Technology, Pune. 4](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-4-320.jpg)

![Applications

• Training neural networks.[2]

• Electrical engineering.

– Determining the sectionalizing switch to be operated in order to solve the

distribution system loss minimization problem.

– The accident diagnosis in a power nuclear power plant.

– Capacitor placement in distribution systems with an objective of improving the

voltage profile and reduction of power loss.

• Data mining.

• Mechanical engineering.

– Modelling and optimization of process parameters of wire electrical discharge

machining.

– Parameter optimization of a multi-pass milling process.

– Parameter optimization of ultrasonic machining process.

– Optimization of mechanical draft counter flow wet-cooling tower .

• Civil engineering.

– Locate the subway routes which aims to maximize the population covered by

subway routes.

– Structural optimization of planar and space trusses under stress, displacement and

buckling constraints.

June 27, 2017 Maharashtra Institute of Technology, Pune. 5](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-5-320.jpg)

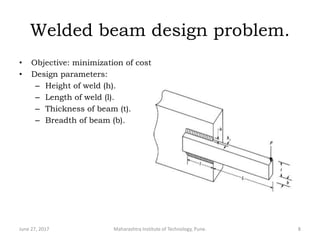

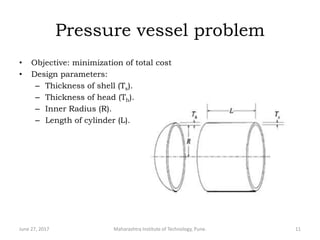

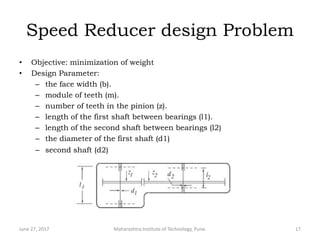

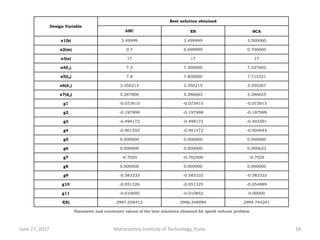

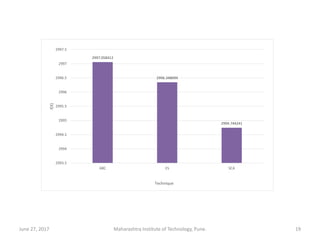

![Benchmark problems

• In order to evaluate the performance of the ABC algorithm

well-known standard engineering problems are used[3].

• These problems are

1. Welded beam design problem.

2. Pressure vessel problem.

3. Tension/compression spring problem.

4. Speed reducer design problem.

June 27, 2017 Maharashtra Institute of Technology, Pune. 7](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-7-320.jpg)

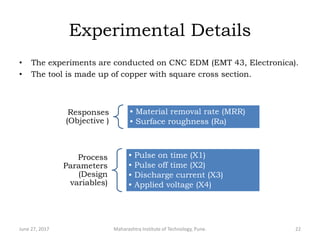

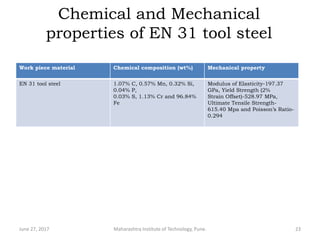

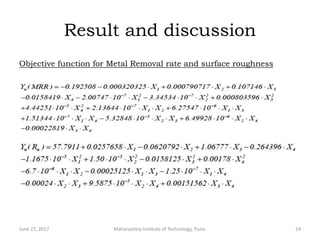

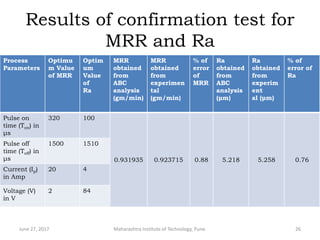

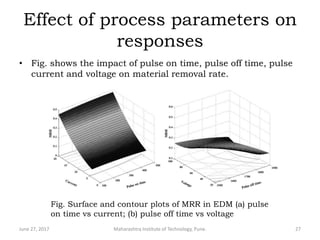

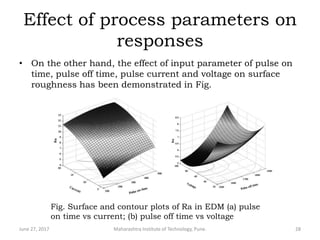

![Optimization of

MRR and Surface Roughness in EDM of EN31

tool steel

• The objective here is to find out the combination of process

parameters for optimum surface roughness and material removal

rate (MRR) in electro discharge machining (EDM) of EN31 tool steel

using artificial bee colony (ABC) algorithm.

• For experimentation, machining parameters viz., pulse on time,

pulse off time, discharge current and voltage are varied based on

central composite design (CCD).

• From ABC analysis, the optimum combinations of process

parameters are obtained and corresponding values of maximum

MRR and minimum Ra are found out.[4]

June 27, 2017 Maharashtra Institute of Technology, Pune. 21](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-21-320.jpg)

![Optimization of shell and

tube heat exchangers

• Design and economic optimization of shell and tube heat exchangers

using Artificial Bee Colony (ABC) algorithm[6].

• Artificial Bee Colony (ABC) has been applied to minimize the total cost of the

equipment.

• The traditional design method for shell and tube heat exchangers involves

rating a large number of different exchanger geometries to identify those that

satisfy a given heat duty and a set of geometric and operational

constraints[6].

June 27, 2017 Maharashtra Institute of Technology, Pune. 30](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-30-320.jpg)

![Optimization design of heat exchanger

design and objective function

• Tube Sheet Patterns and Pitch

• The Fouling Resistances

• The Thermophysical Properties Of

Fluids

fixed

parameters

• Shell inside diameter

• Tube outside diameter

• The number of tube side passages

• Baffles spacing

Optimization

variables

June 27, 2017 Maharashtra Institute of Technology, Pune.

Design variables

The objective function[5]:

Total cost Ctot

Ctot = Ci + CoD

where,

Ci= Capital Investment

CoD = operating cost

Ci is a function of exchanger

surface ‘S’

CoD is related to pumping power

to overcome frictional losses

31](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-31-320.jpg)

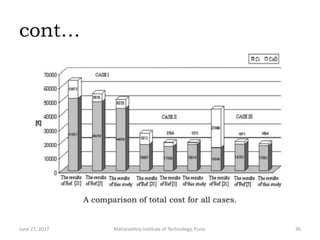

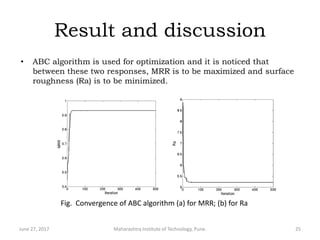

![Result and discussion

• Artificial Bee Colony (ABC) algorithm was used as a optimization algorithm

for design and economic optimization of shell and tube heat exchangers[6].

• The original design specifications for comparing with available literature

approaches and reliability of obtained results were used[6].

June 27, 2017 Maharashtra Institute of Technology, Pune.

Design specifications for different case studies

32](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-32-320.jpg)

![cont..

June 27, 2017 Maharashtra Institute of Technology, Pune. 33

Case study-1

The results of Ref.

[7]

The results of Ref.

[8]

The results of this

study

Ds (m) 0.894 0.83 1.3905

B (m) 0.356 0.5 0.4669

do (m) 0.02 0.016 0.0104

S (m2) 278.6 262.8 230.109

Nt 918 1567 1528

vt (m/s) 0.75 0.69 0.36

vs (m/s) 0.58 0.44 0.118

ht (W/m2K) 3812 3762 3818

hs (W/m2K) 1573 1740 3396

U(W/m2K) 615 660 832

L(m) 4.83 3.379 3.963

Pt (Pa) 6251 4298 3043

Ps (Pa) 35,789 13,267 8390

Ci (€) 51,507 49,259 44,559

Co(€/year) 2111 947 1014.5

CoD (€) 12,973 5818 6233.8

Ctot (€) 64,480 55,077 50,793

Comparison of other results with the results of this study for Case study-1.](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-33-320.jpg)

![cont…

June 27, 2017 Maharashtra Institute of Technology, Pune. 34

Case study-2

The results of Ref.

[7]

The results of Ref.

[8]

The results of this

study

Ds (m) 0.539 0.63 0.3293

B (m) 0.127 0.12 0.0924

do (m) 0.025 0.02 0.0105

S (m2) 61.5 52.9 61.566

Nt 158 391 511

vt (m/s) 1.44 0.87 0.43

vs (m/s) 0.47 0.43 0.37

ht (W/m2K) 619 1168 2186

hs (W/m2K) 920 1034 868

U(W/m2K) 317 376 323

L(m) 4.880 2.153 3.6468

Pt (Pa) 49,245 14,009 1696

Ps (Pa) 24,909 15,717 10,667

Ci (€) 19,007 17,599 19,014

Co(€/year) 1304 440 197.139

CoD (€) 8012 2704 1211.3

Ctot (€) 27,020 20,303 20,225

Comparison of other results with the results of this study for Case study-2.](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-34-320.jpg)

![cont…

June 27, 2017 Maharashtra Institute of Technology, Pune. 35

Case study-3

The results of Ref.

[7]

The results of Ref.

[8]

The results of this

study

Ds (m) 0.387 0.62 1.0024

B (m) 0.305 0.44 0.354

do (m) 0.019 0.016 0.0103

S (m2) 46.6 62.5 54.72

Nt 160 803 704

vt (m/s) 1.76 0.68 0.36

vs (m/s) 1.76 0.68 0.36

ht (W/m2K) 6558 6043 4438

hs (W/m2K) 5735 3476 5608

U(W/m2K) 1471 1121 1187

L(m) 4.88 1.548 2.4

Pt (Pa) 62,812 3673 2046

Ps (Pa) 67,684 4365 2716

Ci (€) 16,549 19,163 17,893

Co(€/year) 4466 272 257.82

CoD (€) 27,440 1671 1584.2

Ctot (€) 43,989 20,834 19,478

Comparison of other results with the results of this study for Case study-3.](https://image.slidesharecdn.com/applicationofabcalgorithm-170627081531/85/Application-of-abc-algorithm-35-320.jpg)