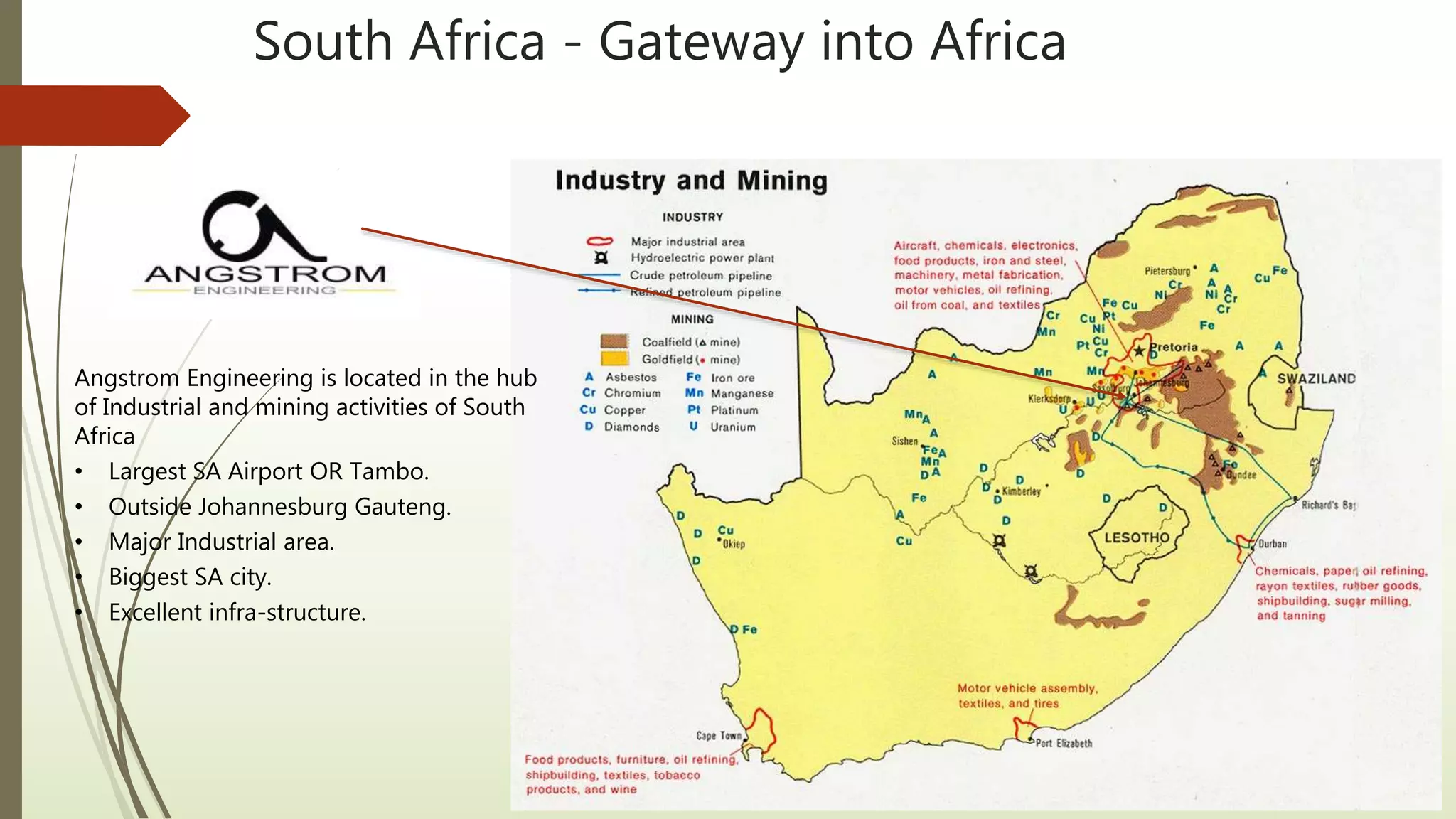

Angstrom Engineering is located in South Africa and provides manufacturing, repair, sourcing, and engineering services to clients in South Africa and internationally. It has various subsidiary companies and is part of the VaalMac Investments group. Angstrom has modern facilities and skilled personnel. It partners with international companies and has quality management systems certified to ISO standards. Angstrom aims to provide world-class industrial services and support clients' needs.