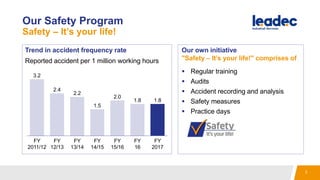

This document discusses an engineering services company's safety program and global operations. It outlines the company's initiatives to reduce accidents, including regular training, audits, and safety measures. Charts show declining accident rates over time. The company has received numerous safety awards from customers in recognition of its strong safety record. Globally, it has nearly 20,000 employees and a presence in 14 countries across North America, South America, Asia, and Europe.