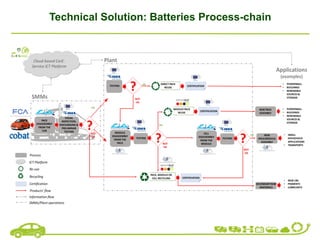

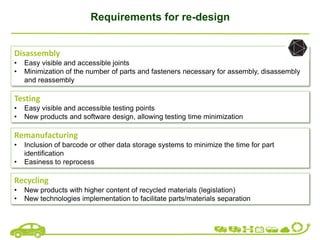

The project, funded by the EU's Horizon 2020 program, focuses on enhancing the recycling processes for automotive components, particularly in the context of electric vehicles (EVs). Key objectives include analyzing current practices, identifying regulatory hurdles, and developing innovative solutions for end-of-life components to make them more reusable and recyclable. Recommendations include improving disassembly techniques, addressing legislation gaps, and encouraging the use of recycled materials in new products.