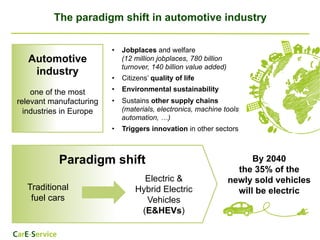

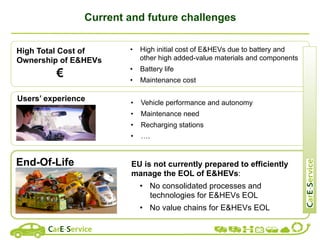

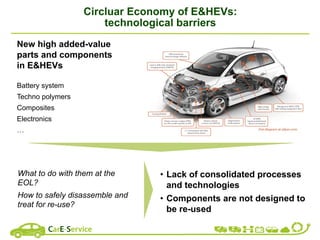

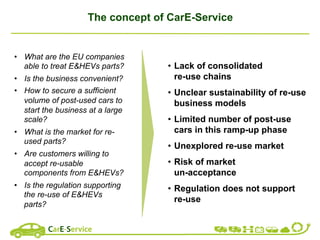

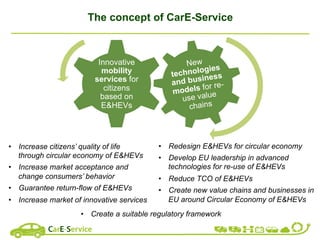

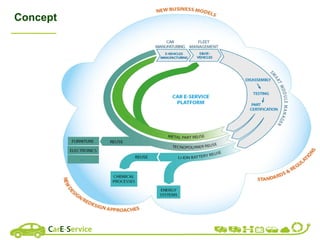

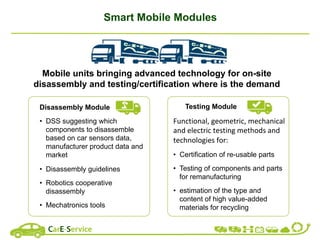

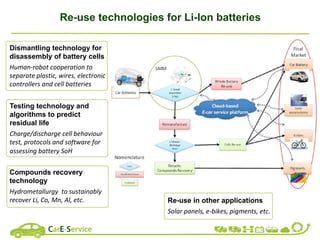

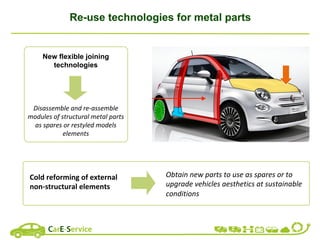

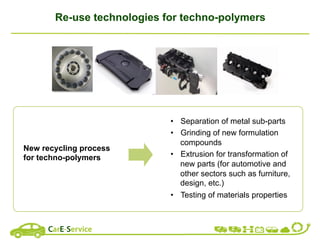

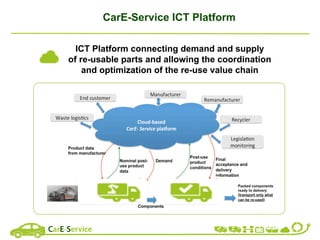

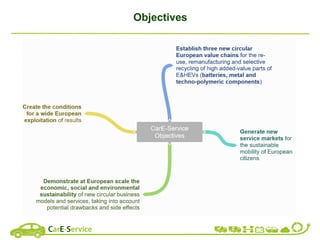

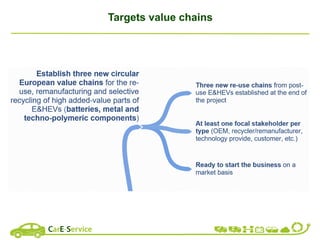

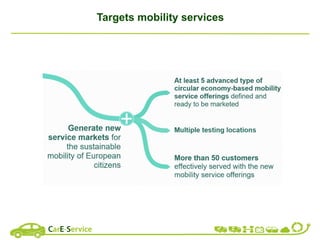

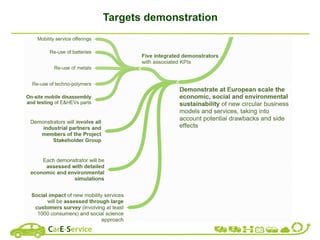

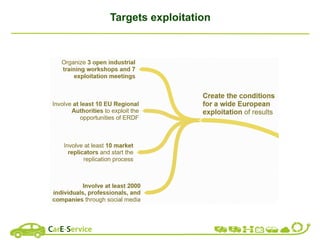

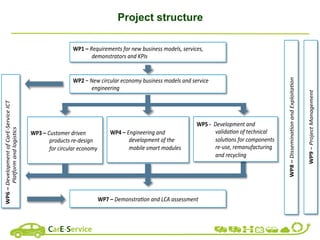

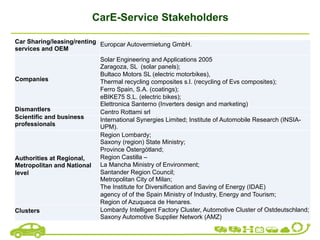

The project aims to drive innovation and sustainability in the automotive industry by promoting the transition to electric and hybrid vehicles, addressing challenges related to cost, management, and end-of-life solutions. It emphasizes establishing circular economy practices, developing new technologies for component reuse, and creating mobility services that enhance citizens' quality of life. The project's structure includes various work packages focused on business models, engineering, and the development of an ICT platform for supply and demand coordination of re-usable parts.