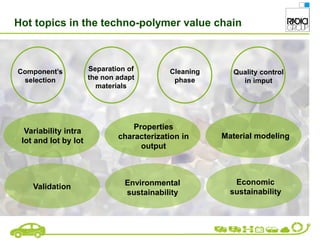

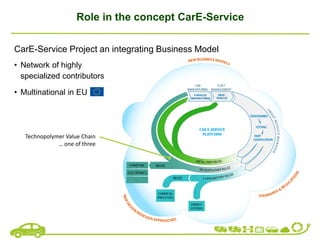

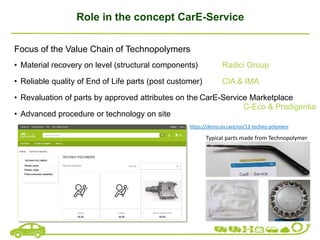

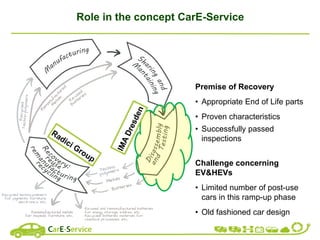

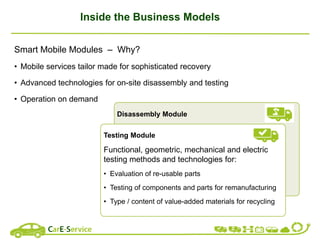

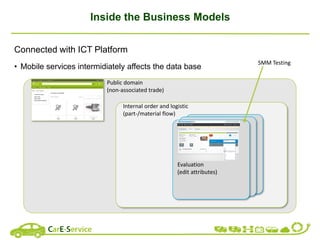

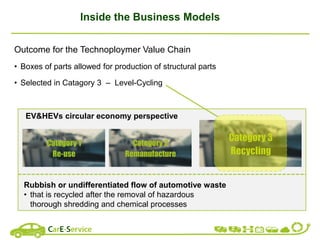

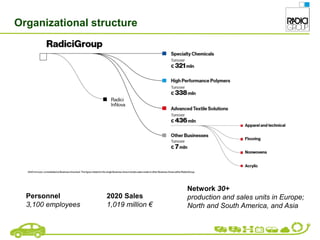

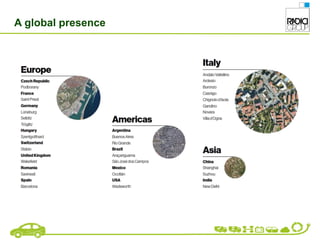

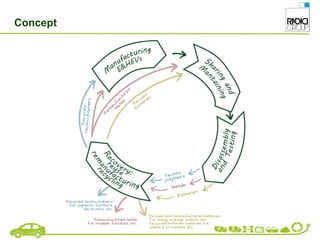

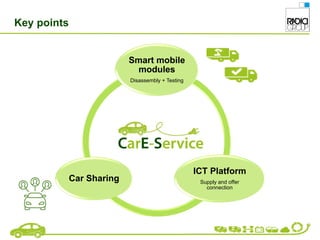

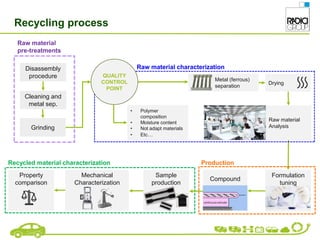

The document details the Car-E Service project, funded by the EU's Horizon 2020 program, focusing on the feasibility of automotive polyamide circularity through recycling and sustainable practices in the automotive sector. It includes information on the project's agenda, participant roles, and the environmental impact of using post-consumer recycled materials, as well as technical demonstrations and methodologies for disassembly and remanufacturing vehicles. The initiative emphasizes collaboration among various stakeholders to promote a circular economy in hybrid and electric vehicle components.

![Environmental Impact

[*] In agreement with ISO14040 Life

Cycle Assessment standard](https://image.slidesharecdn.com/29th-june-demonstration-on-techno-polymer-recycling-and-testing-211126082715/85/Automotive-polyamide-circularity-Yes-it-s-feasible-29-320.jpg)