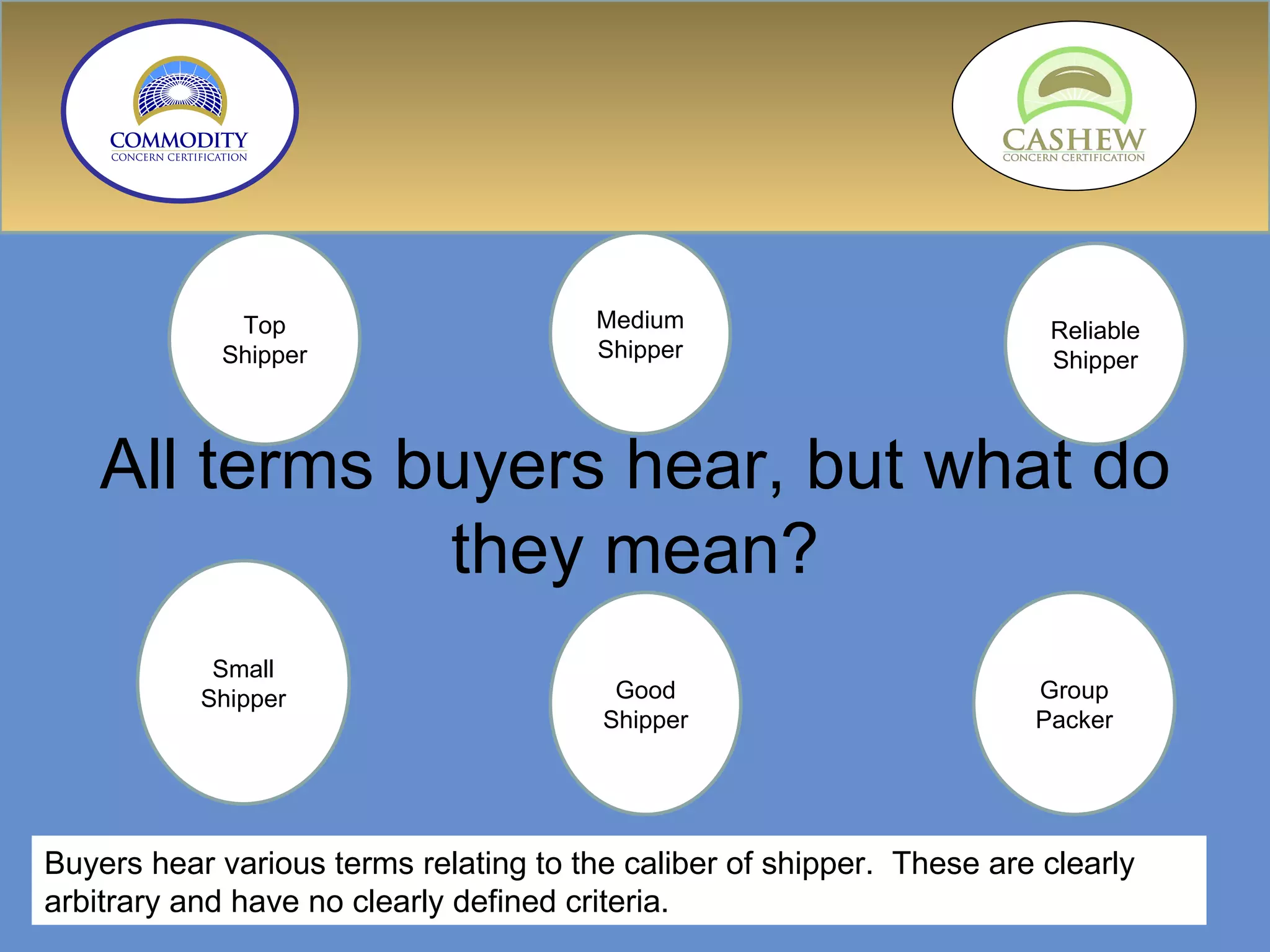

The document discusses the importance of proactive measures in food safety and sourcing to prevent costly incidents, citing examples from various industries. It emphasizes the need for traceability and the implementation of good manufacturing practices through verifiable third-party certification. The author calls for the food industry to adapt to changing conditions and suggests that responsible sourcing initiatives must be prioritized to ensure consumer safety.