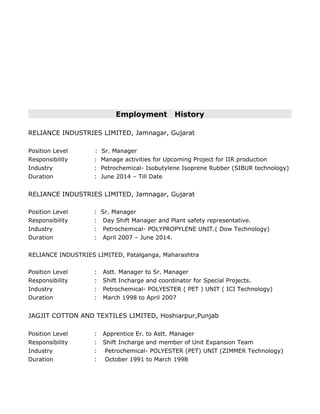

Ajay Kumar Sharma is a 45-year-old Indian national currently working as a Senior Manager at Reliance Industries Limited in Jamnagar, Gujarat. He has over 25 years of experience in the petrochemical industry. His current role involves managing activities for an upcoming Isobutylene Isoprene Rubber production project. He holds a B.Tech in Chemical Engineering and has extensive experience in plant operations and project management.