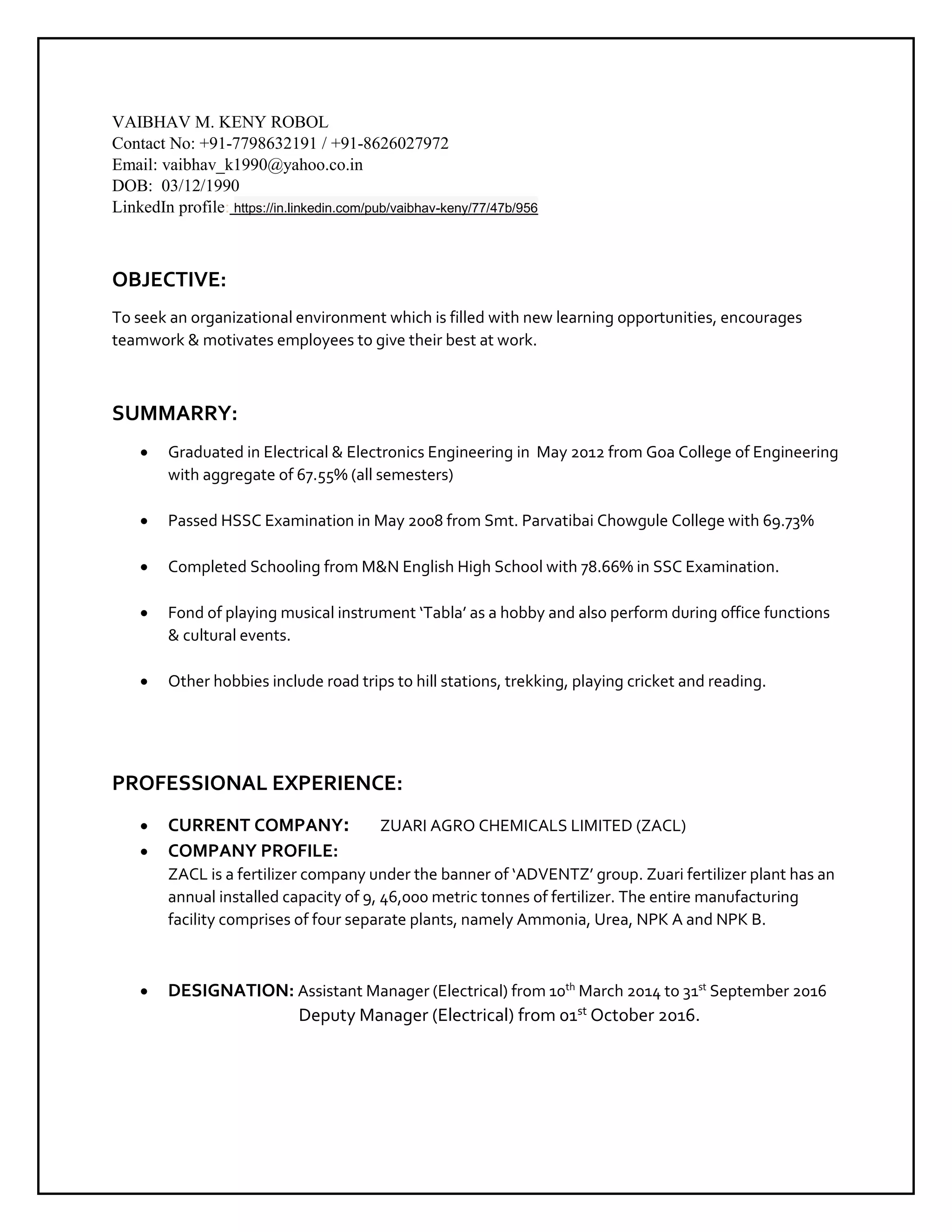

- Vaibhav Keny is seeking a new job opportunity and provides his contact information and educational background graduating with degrees in electrical engineering.

- He has over 3 years of work experience as an Assistant and Deputy Manager in electrical roles at fertilizer companies, executing projects, maintenance, and troubleshooting.

- His responsibilities included power management, equipment maintenance, and overseeing projects like installing transformers and UPS systems.