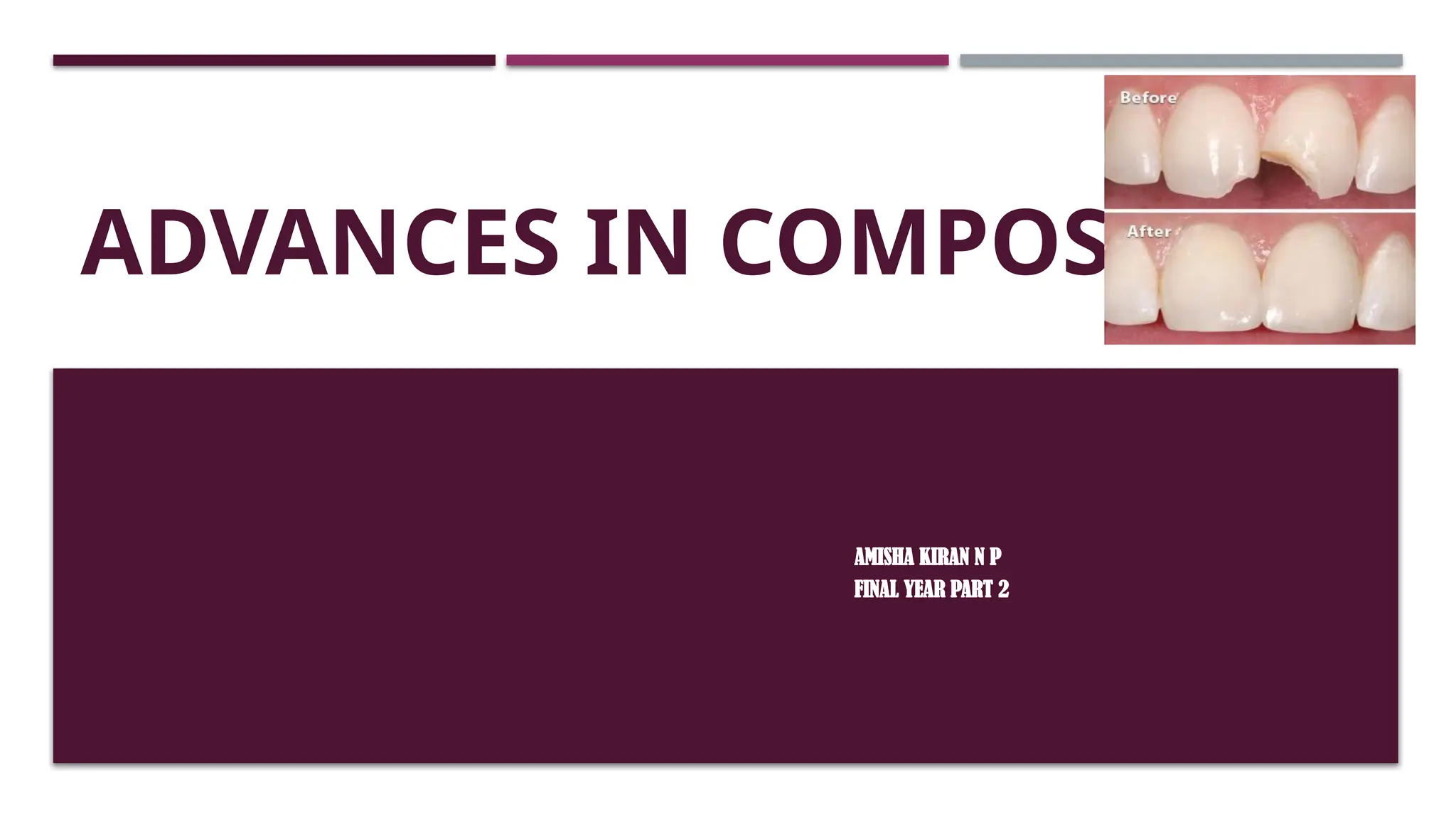

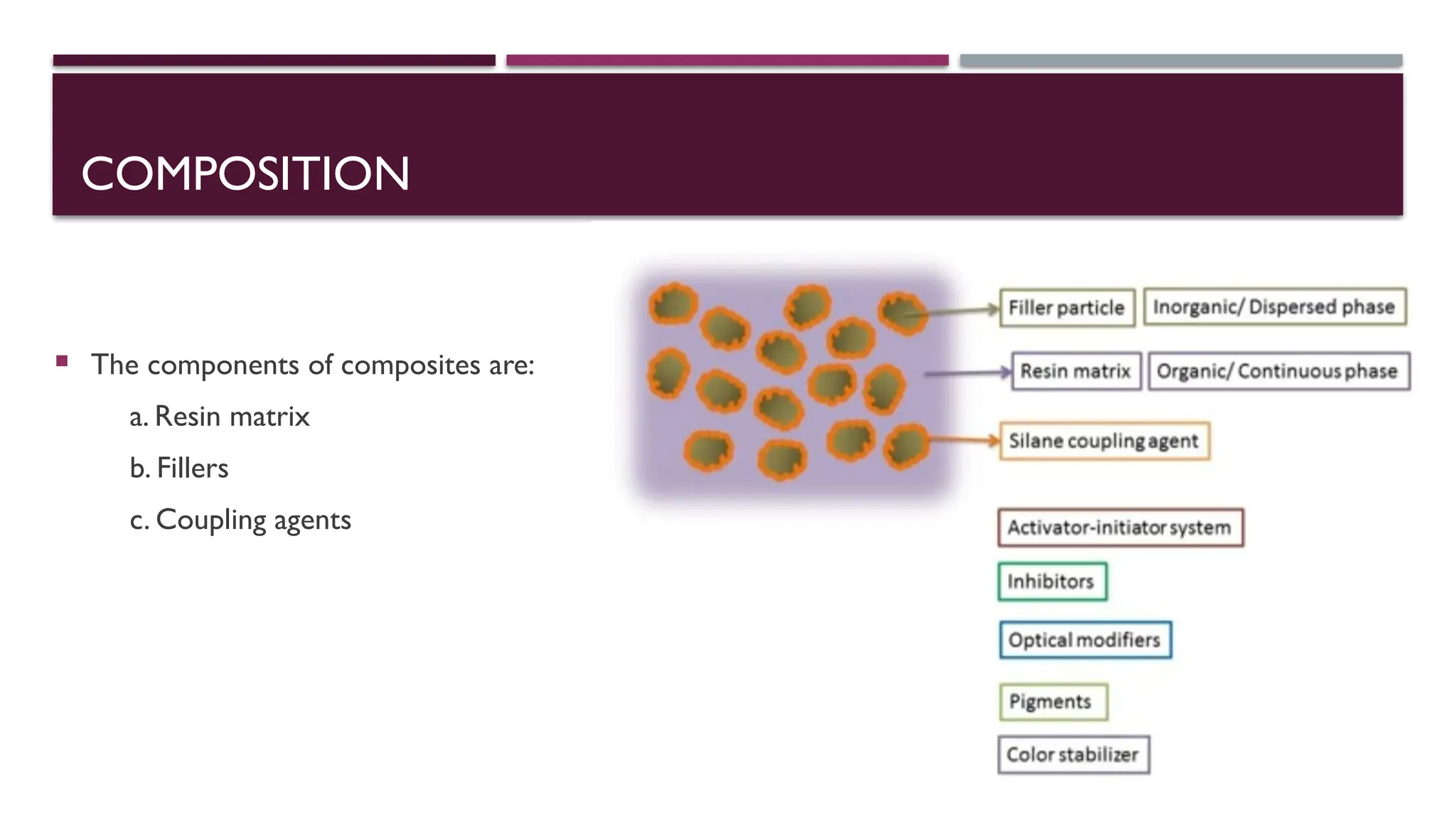

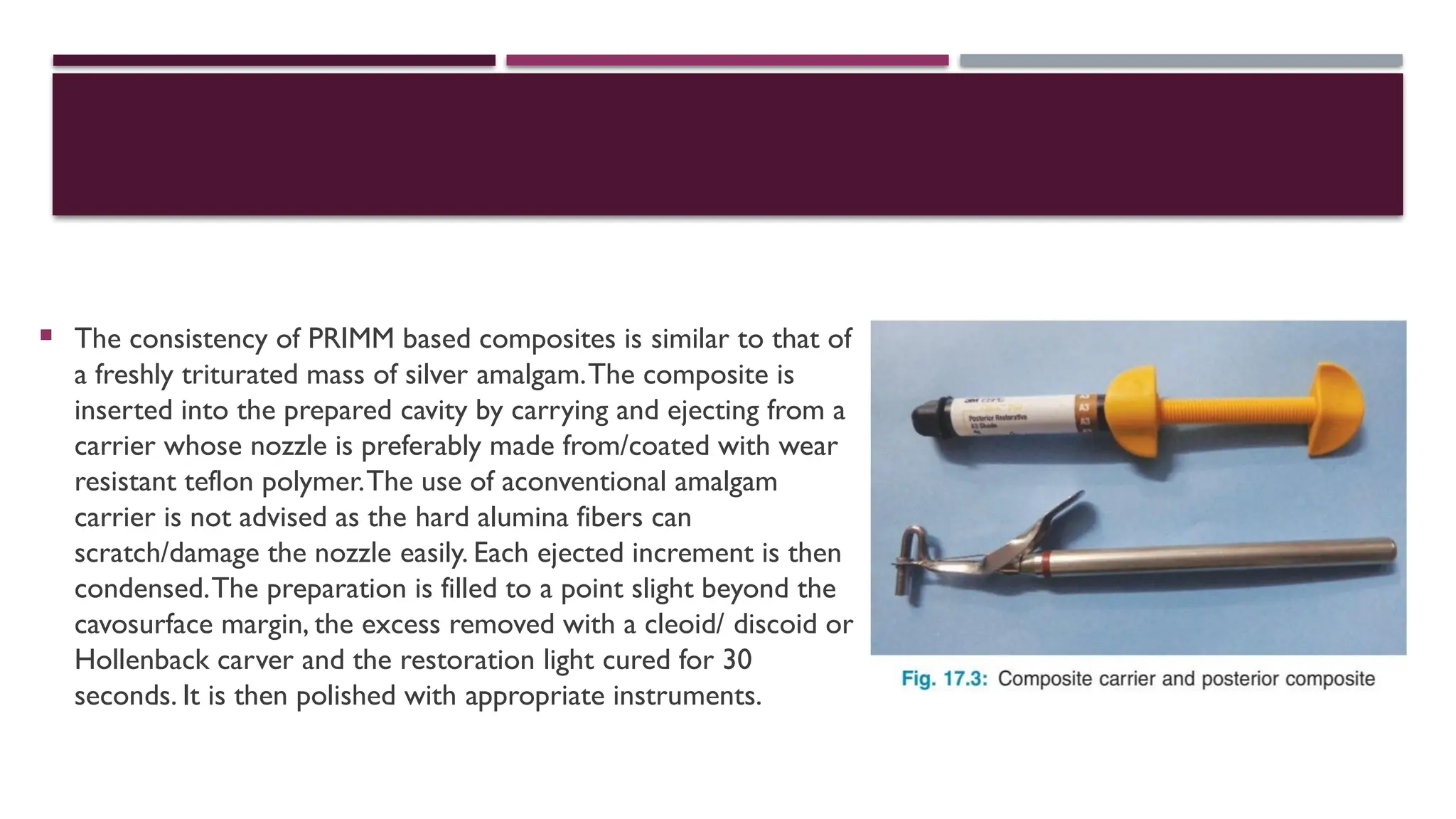

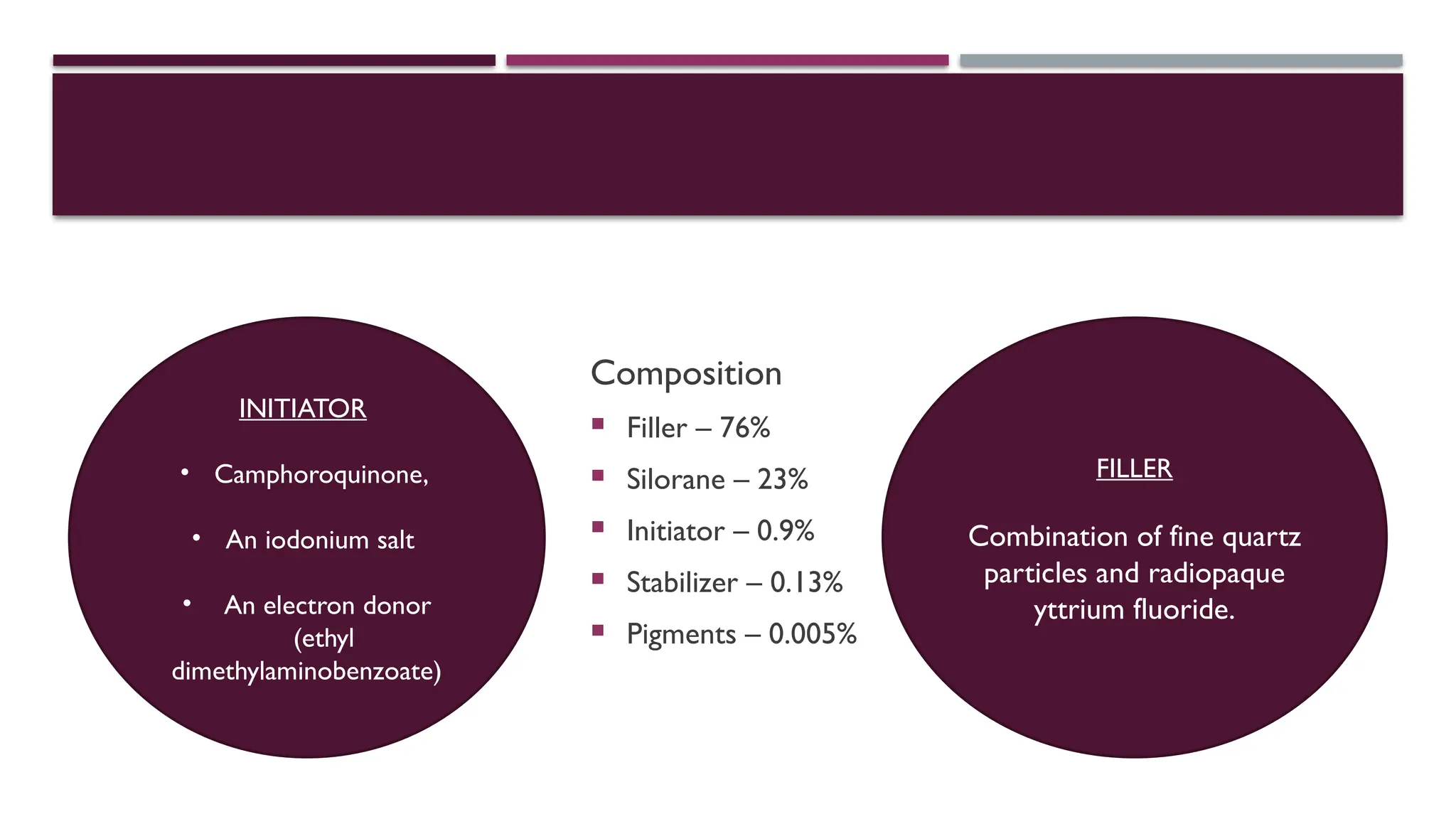

The document discusses the evolution and advancements in composite materials used for dental restorations, beginning with their introduction by R.L. Bowen in 1962. Key developments include the transition from silicate cements to various types of composite materials such as flowable, packable, and antibacterial composites, each designed to address different clinical needs and improve restorative outcomes. Notable innovations also include bioactive composites and nanocomposites, which enhance mechanical properties and reduce issues such as polymerization shrinkage.