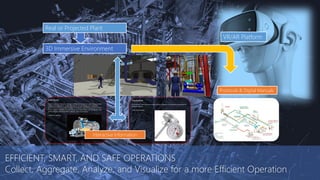

The document discusses the importance of advanced reality technologies, such as VR and AR, in training for Industry 4.0, emphasizing their role in improving workforce efficiency, safety, and decision-making. It highlights the benefits of simulation-based training, which reduces costs and errors while enhancing skill retention and quality. The author, Carlos J. Ochoa Fernández, leverages over 25 years of experience in innovation and digital technologies to advocate for the integration of cutting-edge technologies in workforce training and operational efficiency.