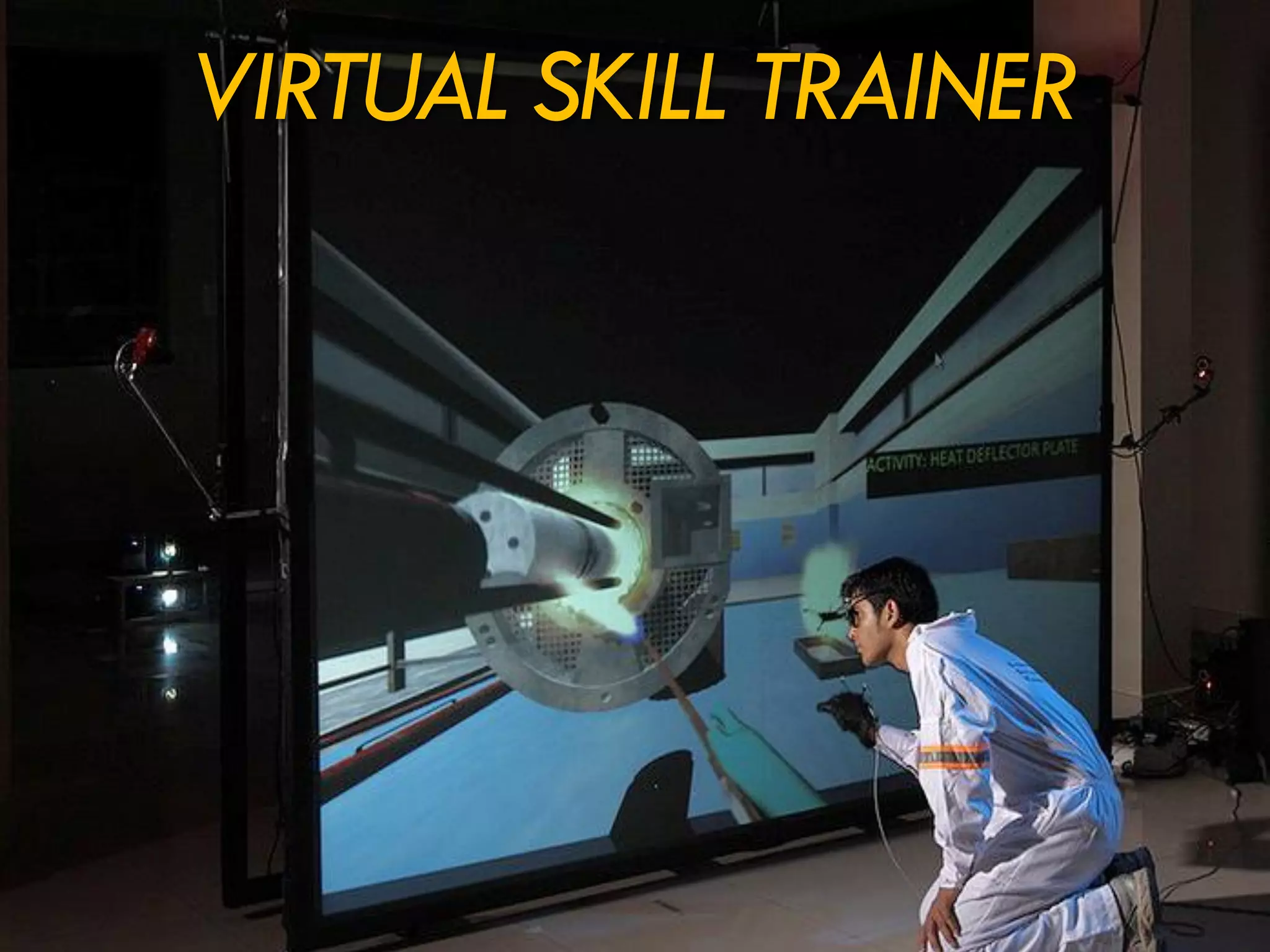

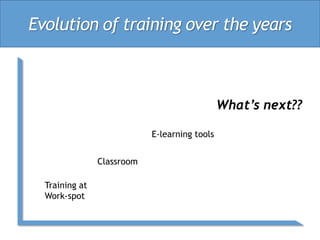

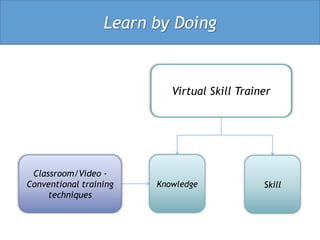

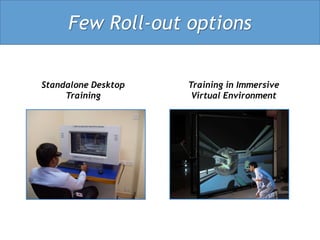

Virtual skill trainers provide experiential learning through simulation without expensive real-world training. Trainees can practice skills repeatedly using virtual simulations until perfecting them. This allows training offline and preparing for work tasks. Trainees learn at their own pace compared to standardized curriculums. Virtual trainers are used for operations training, service tasks like diagnostics and maintenance, and standardizing procedures across different workplace areas. They offer standalone desktop use or immersive virtual environments for training.