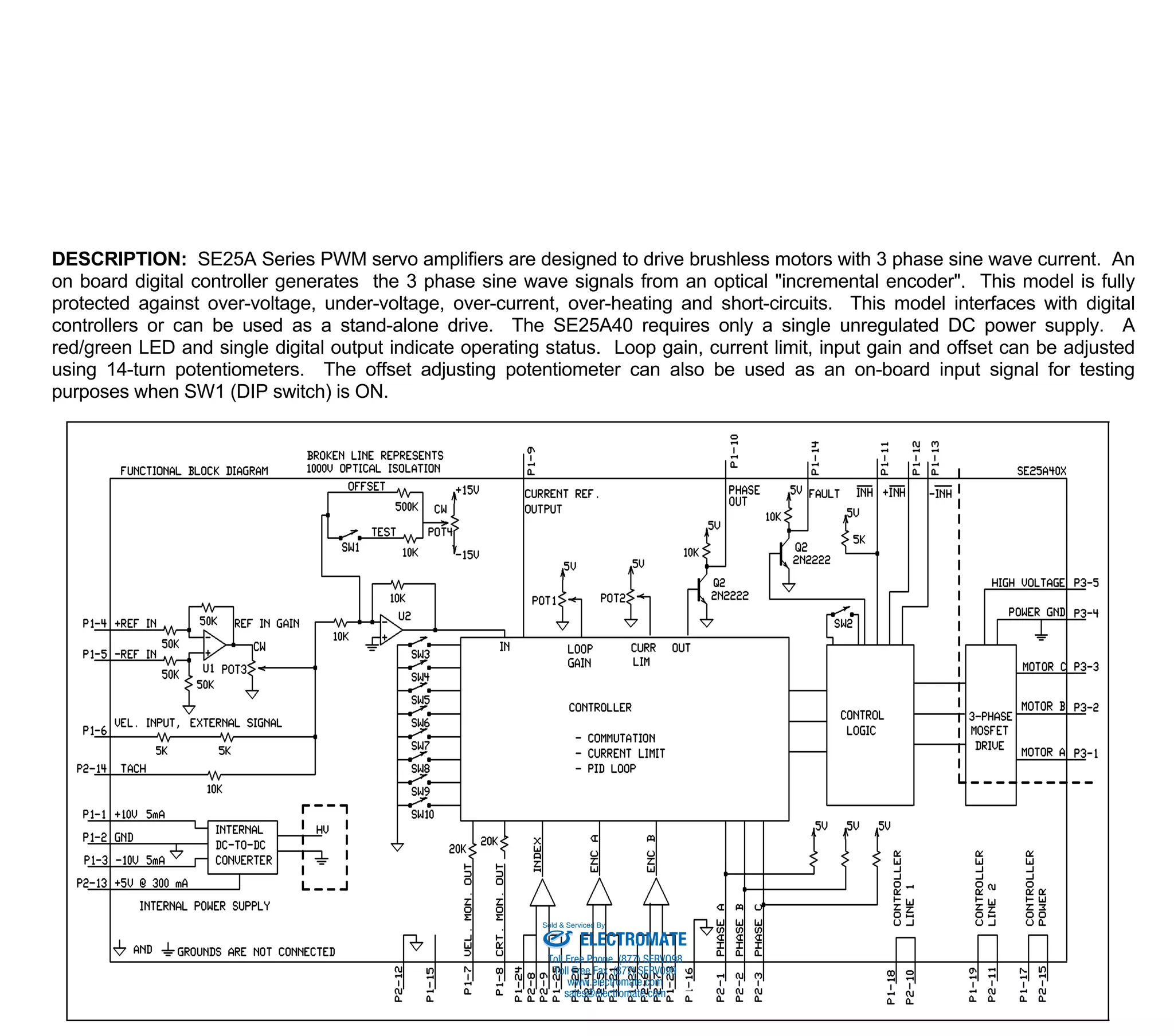

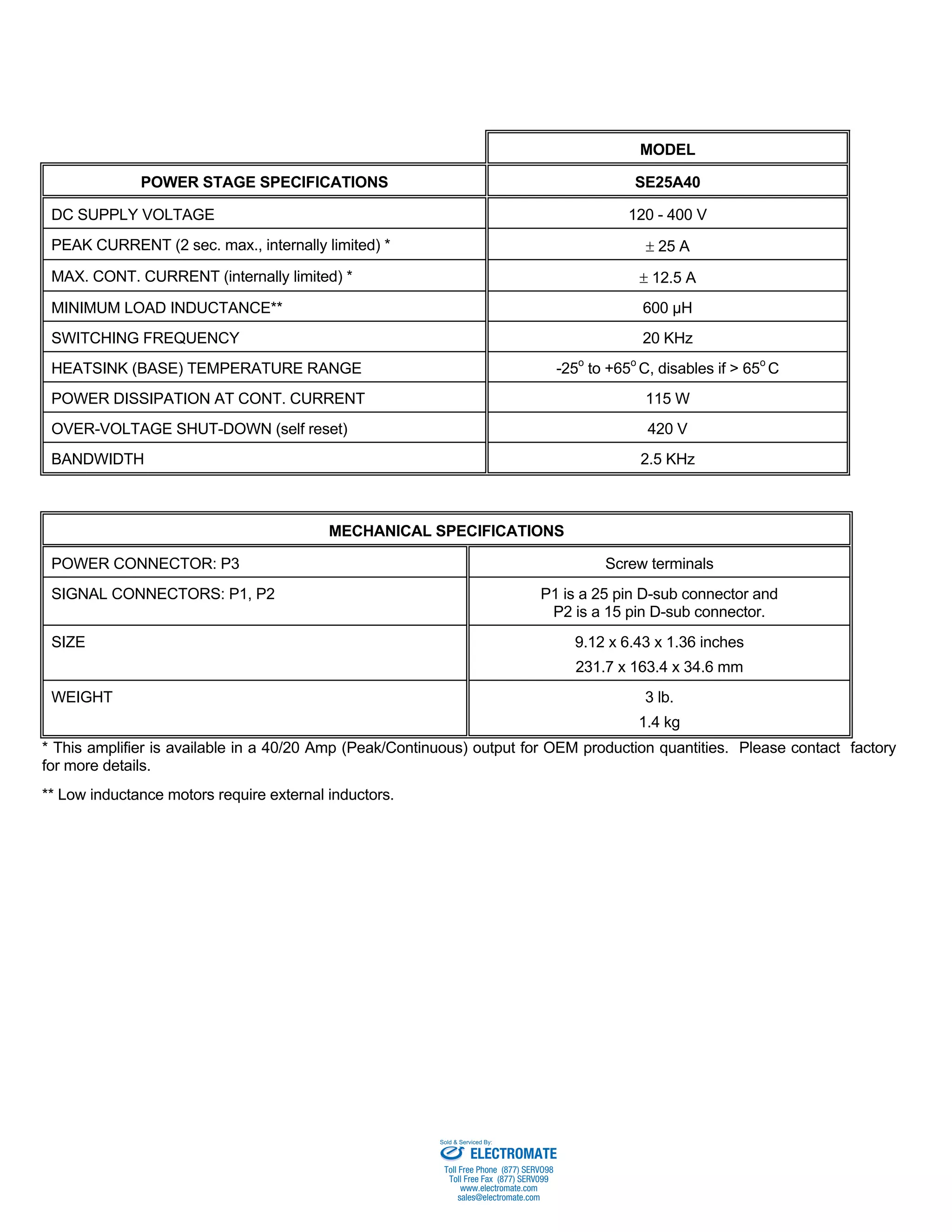

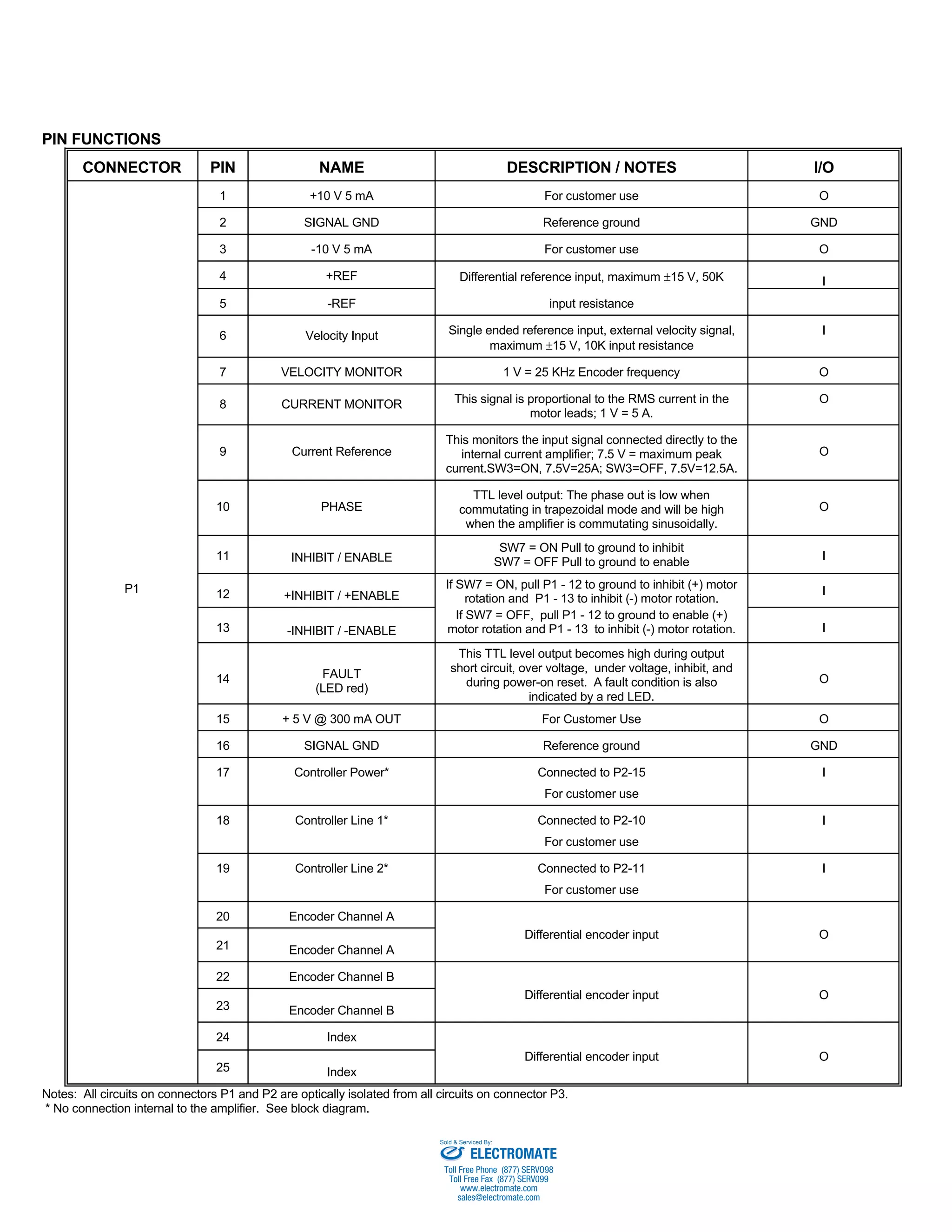

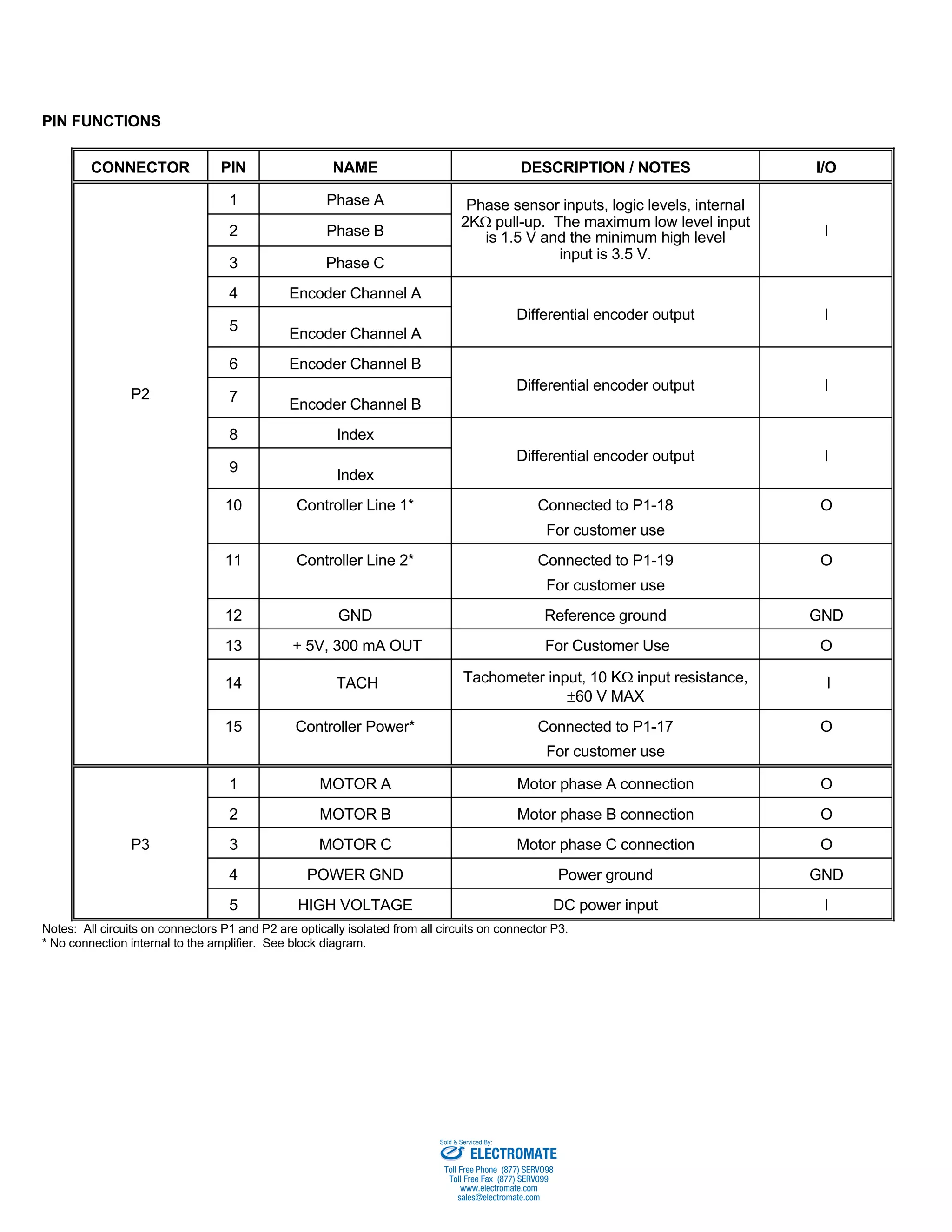

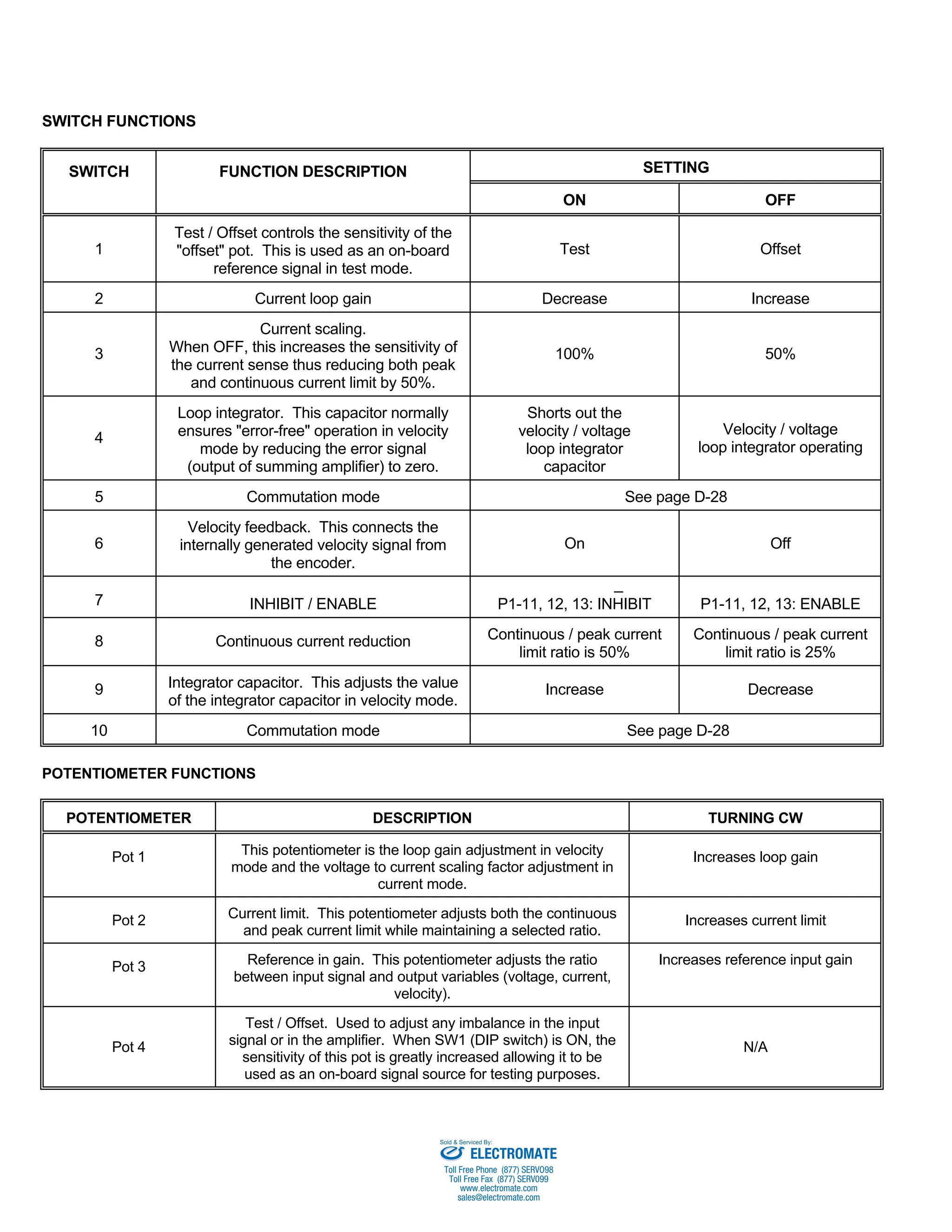

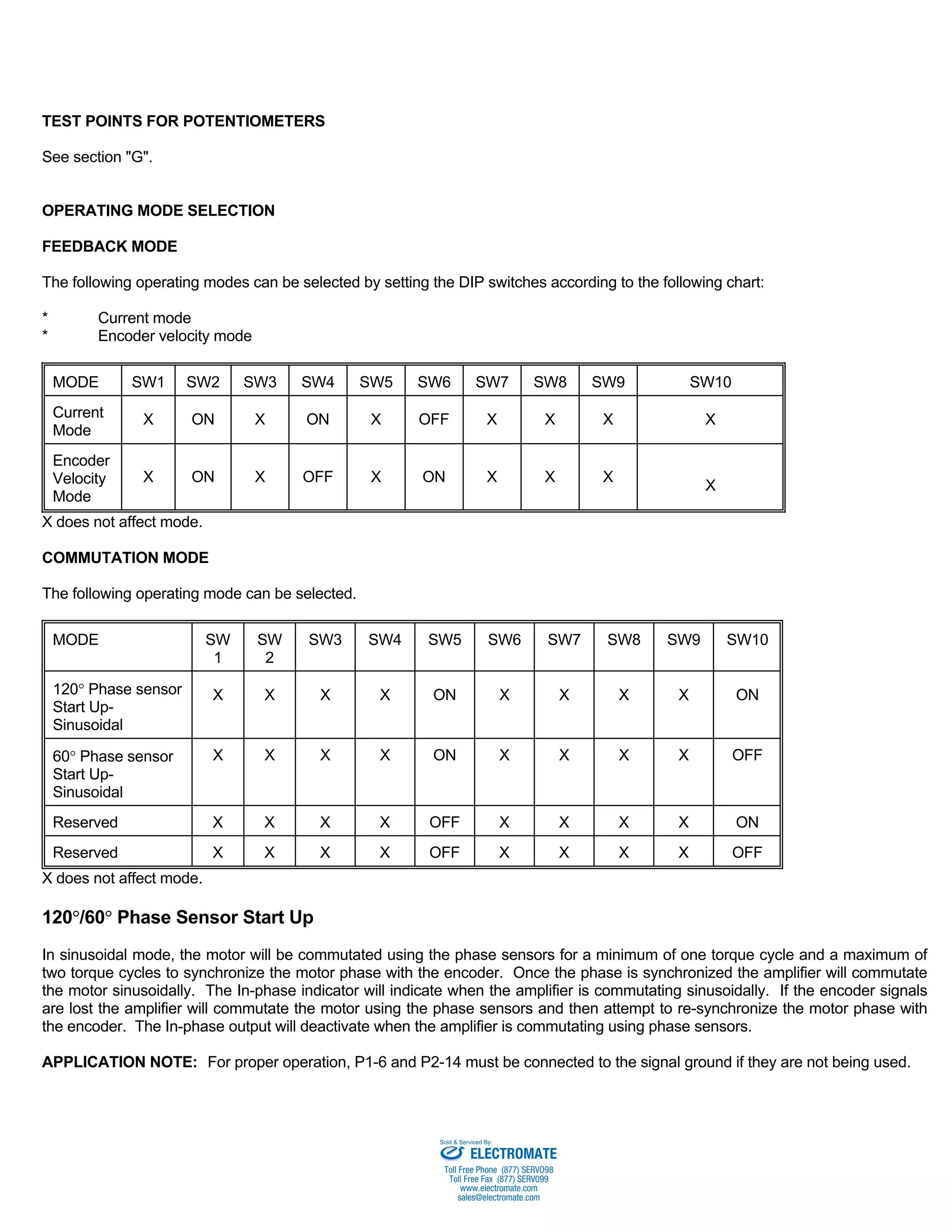

The document describes the SE25A40 brushless servo amplifier. It is a small, surface-mount amplifier that can operate in current or encoder velocity mode. It provides sinusoidal commutation for 3-phase brushless motors from 120-400V DC power. It has protection against overheating, overcurrent, and other faults.