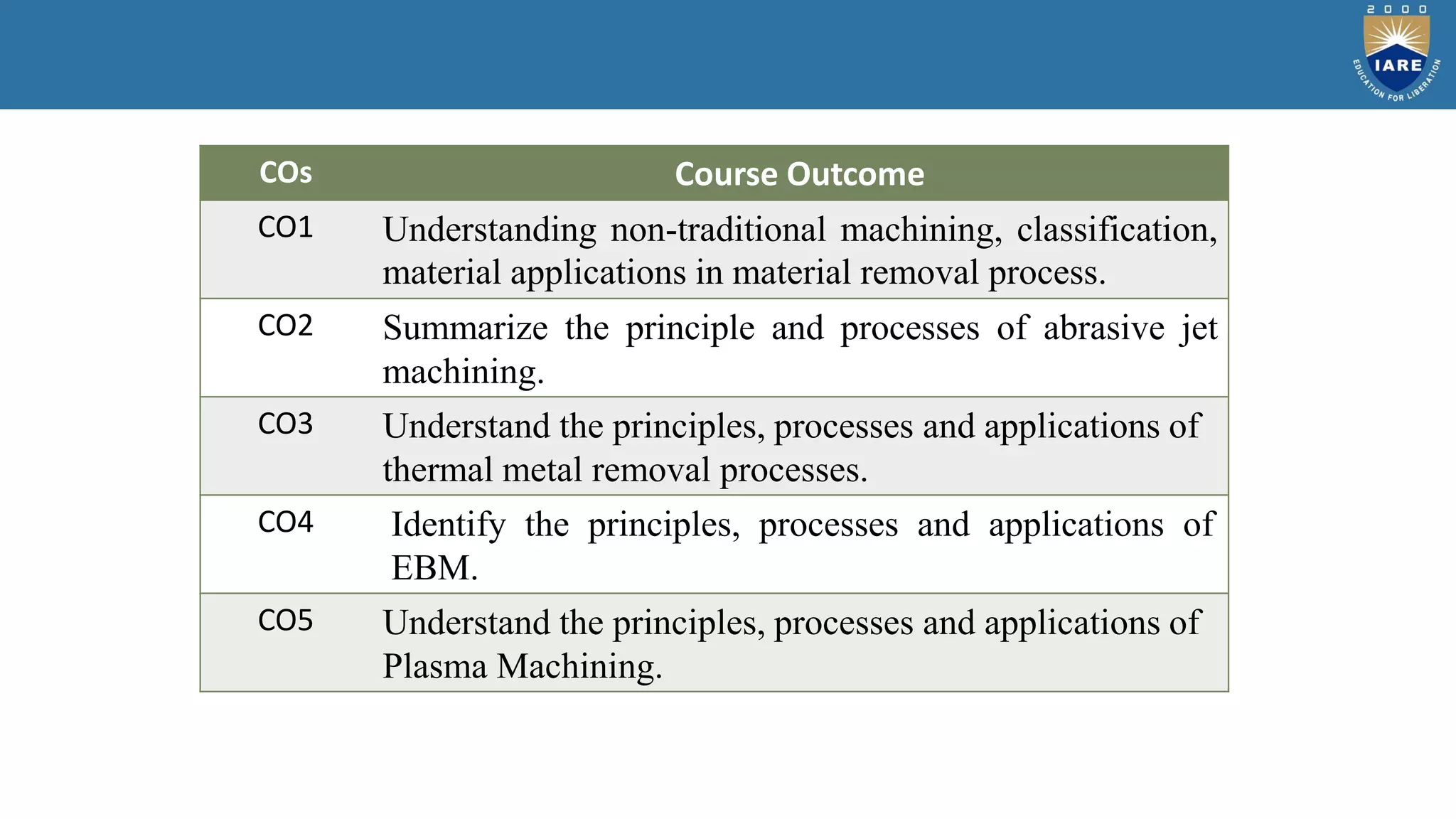

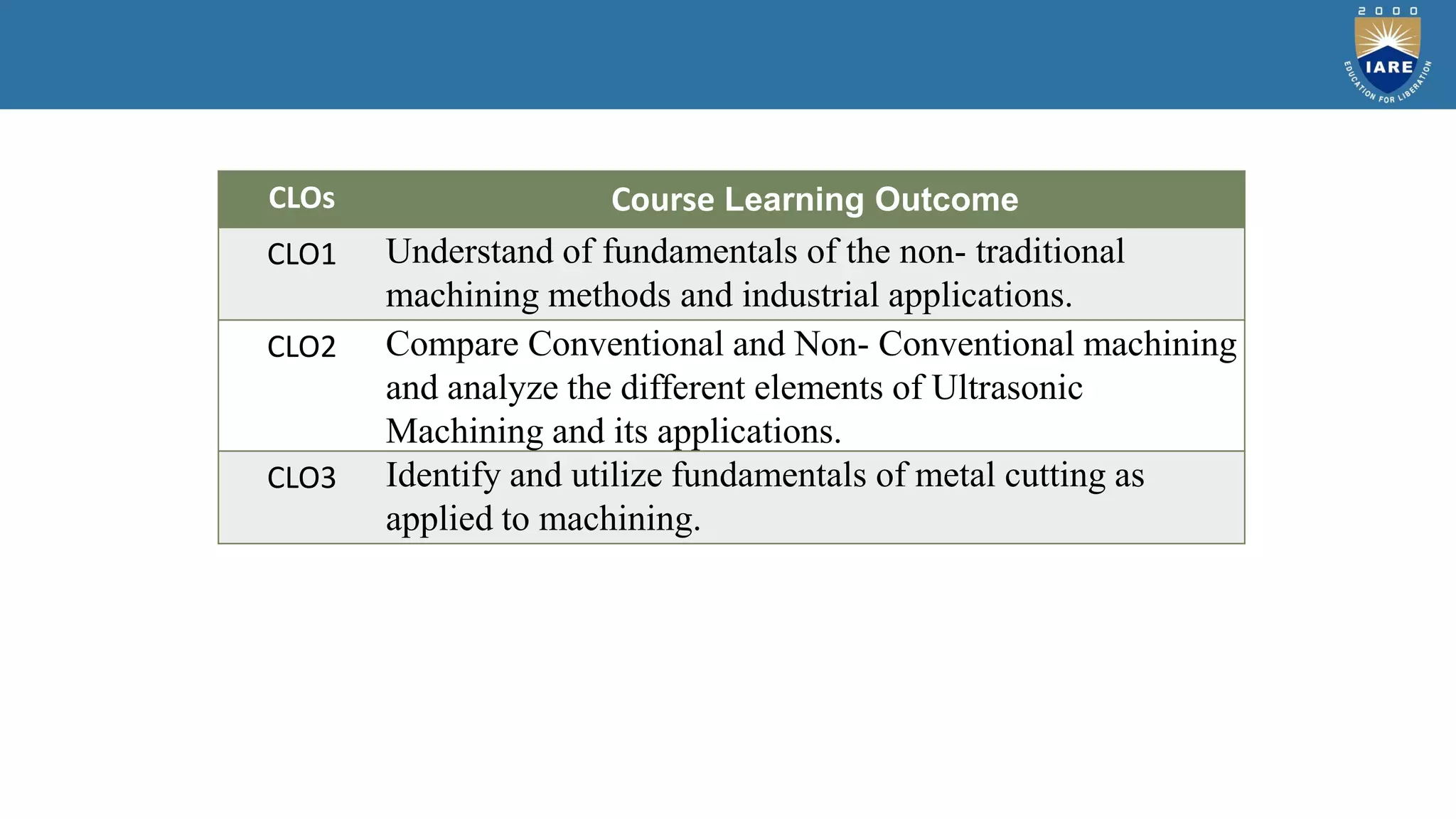

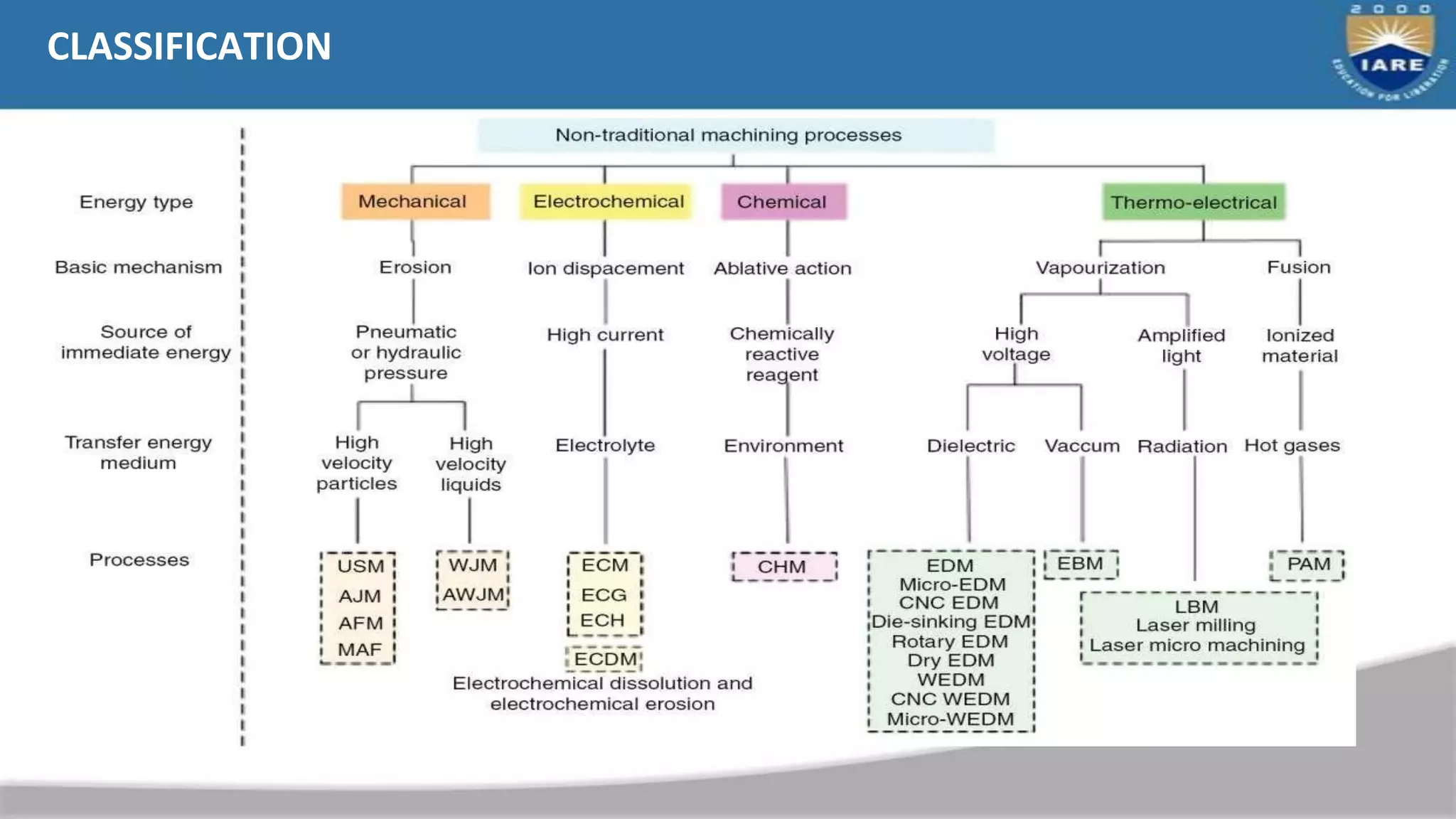

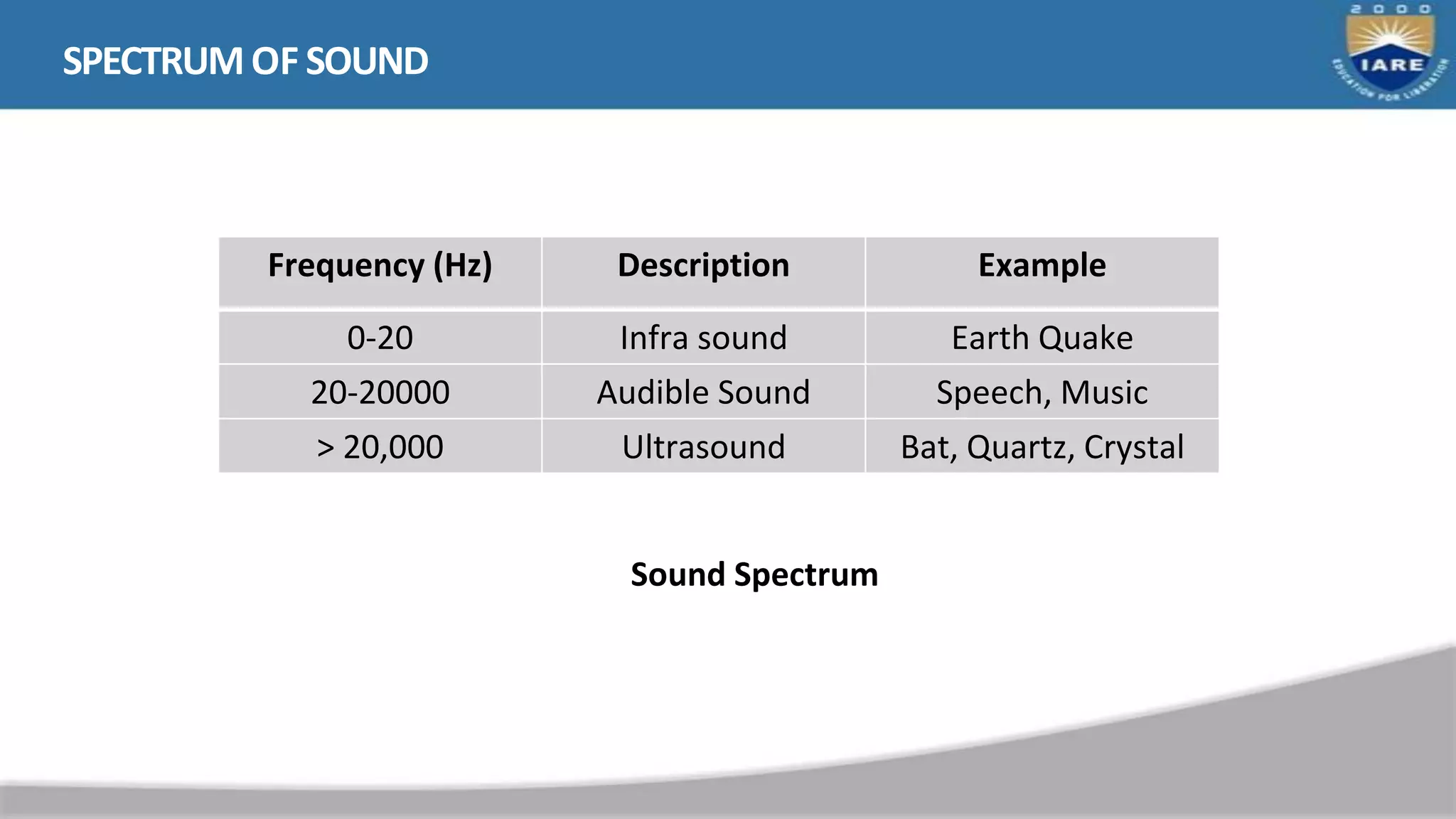

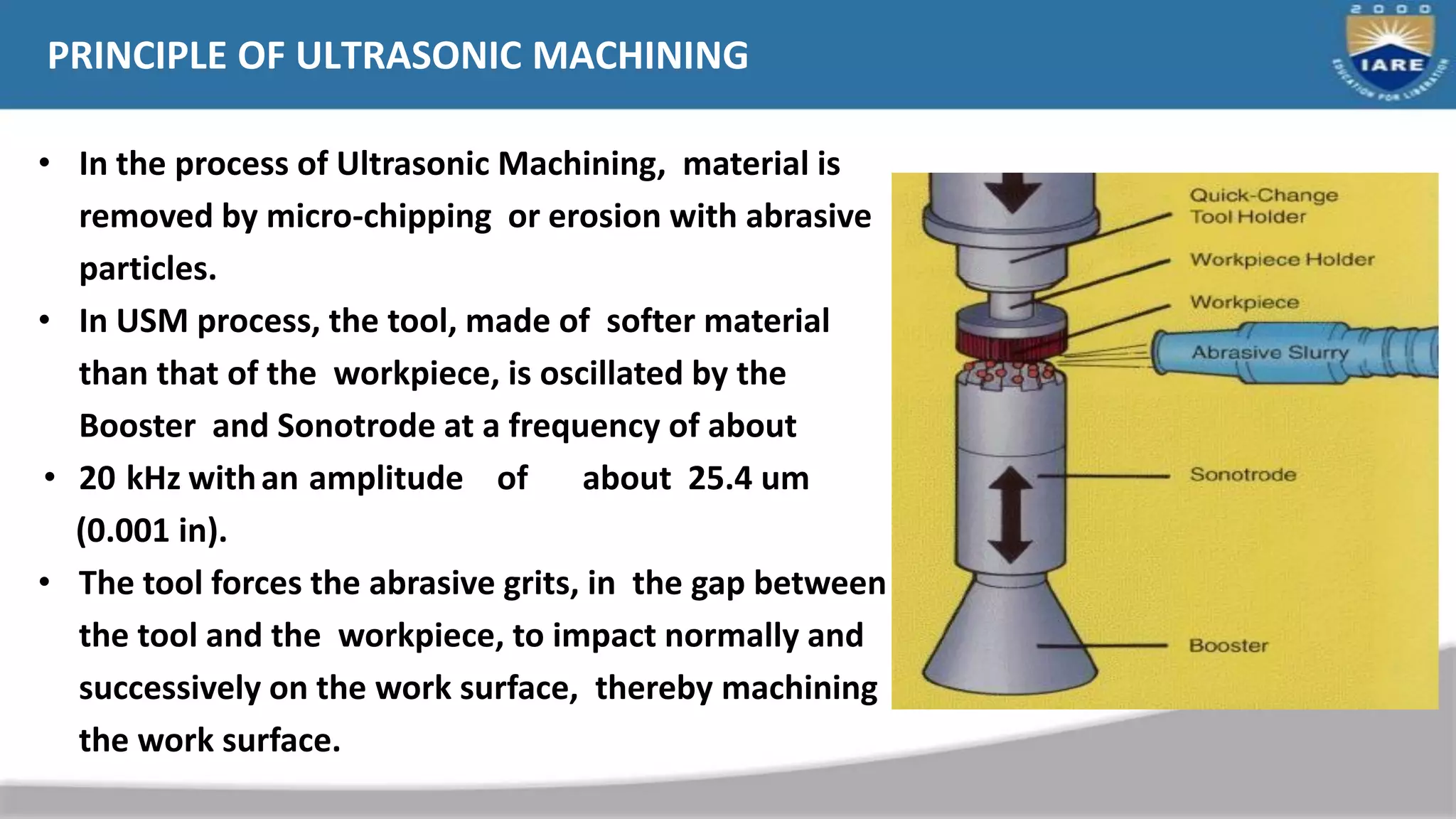

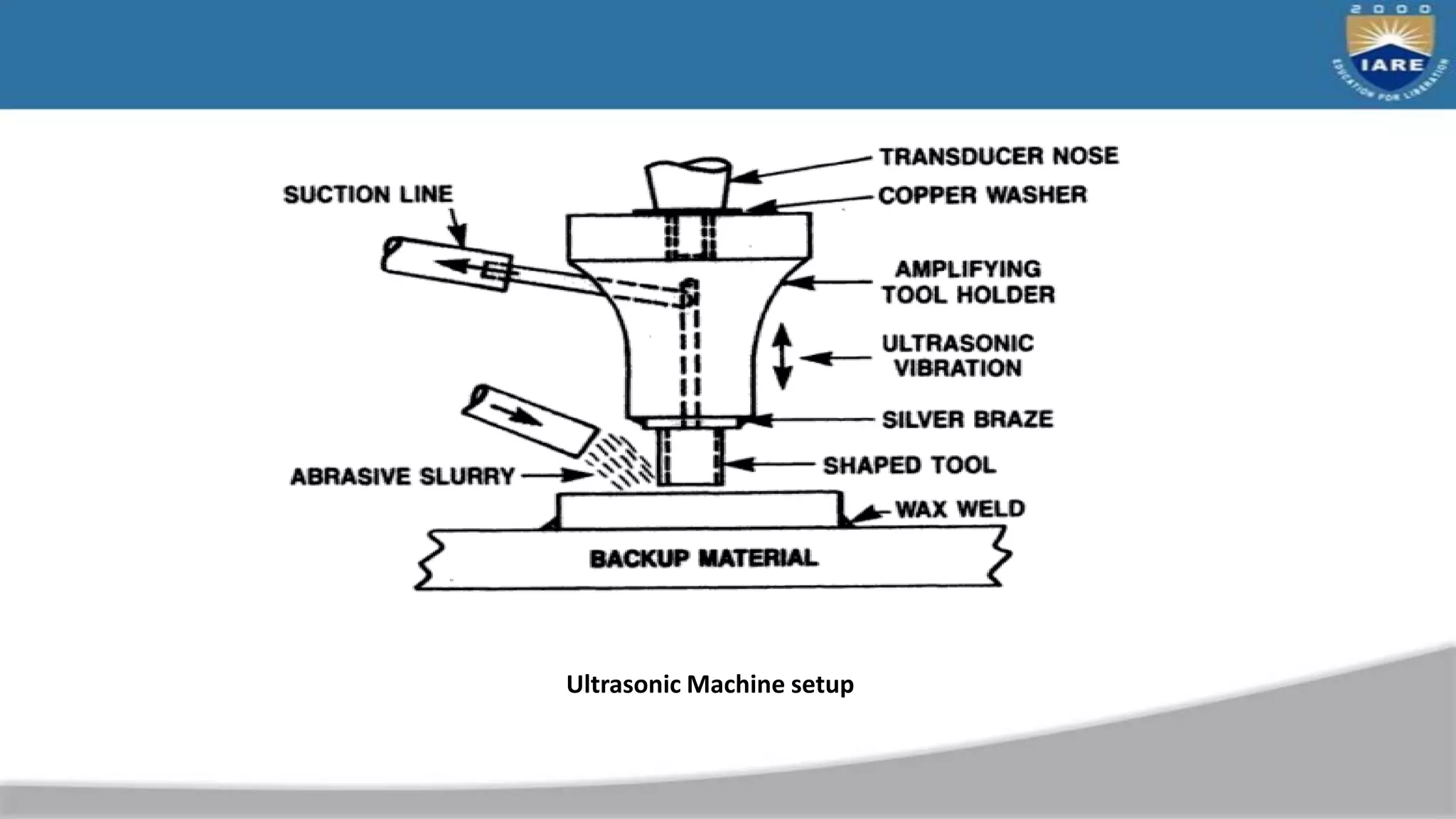

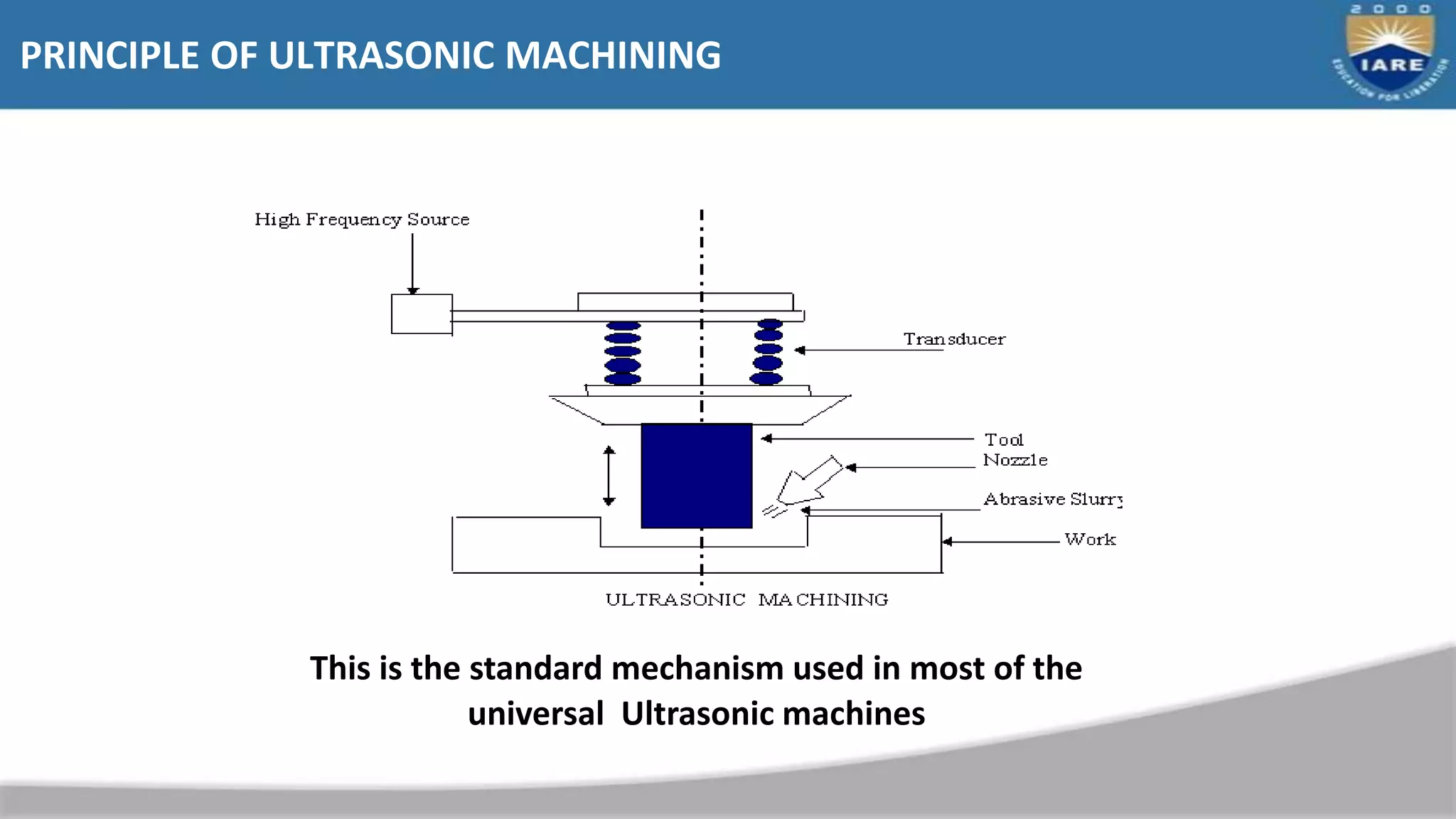

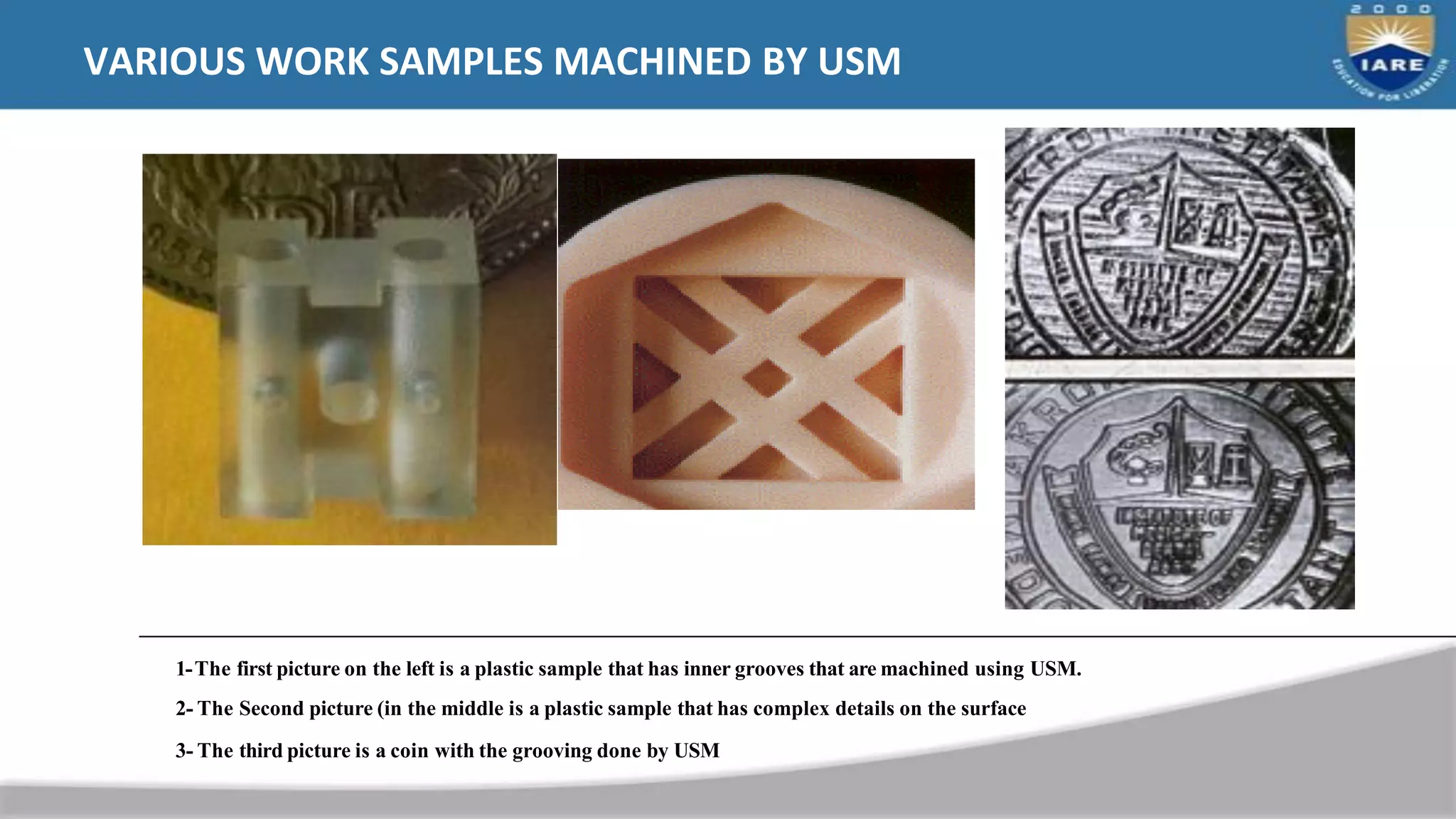

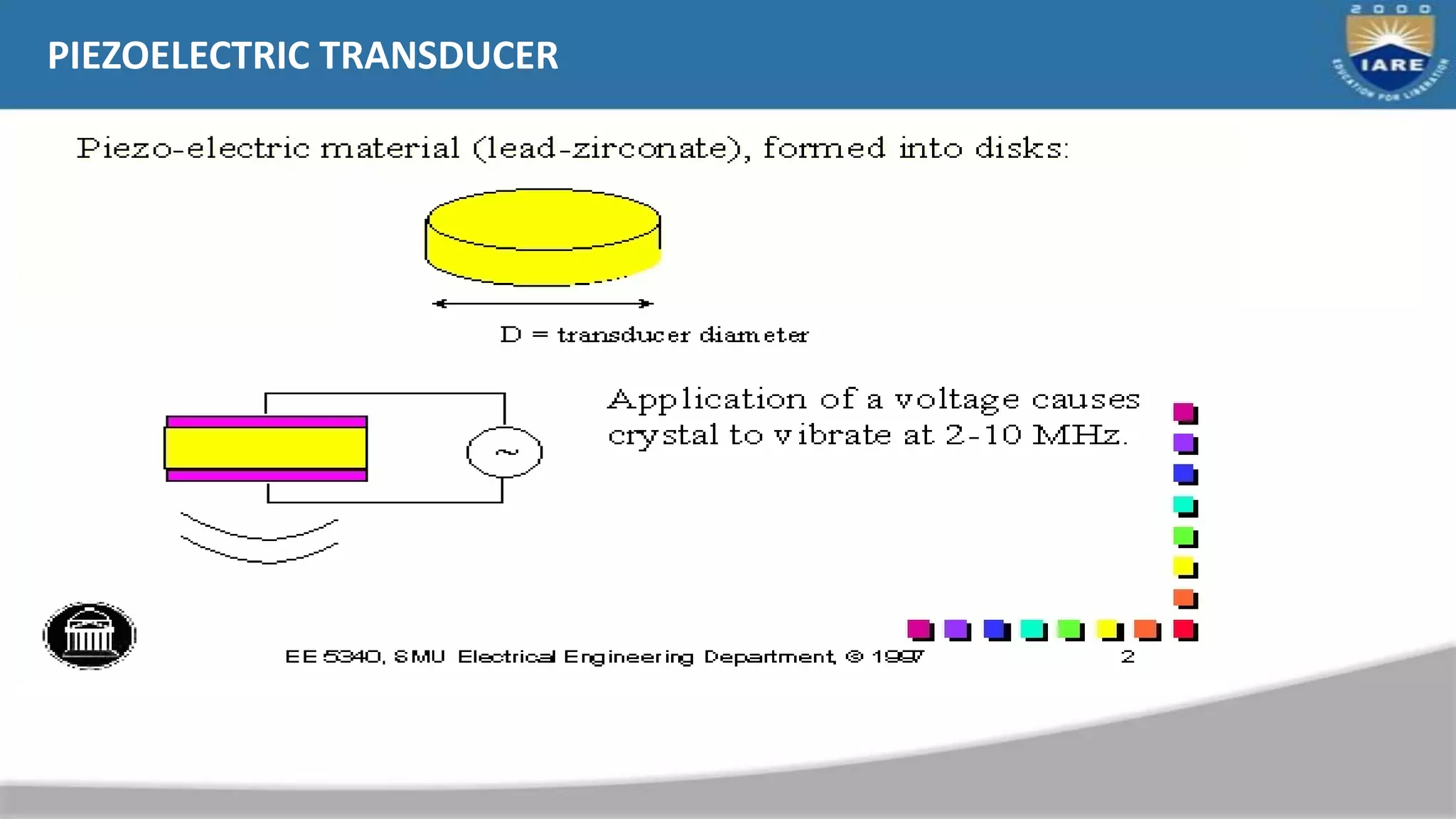

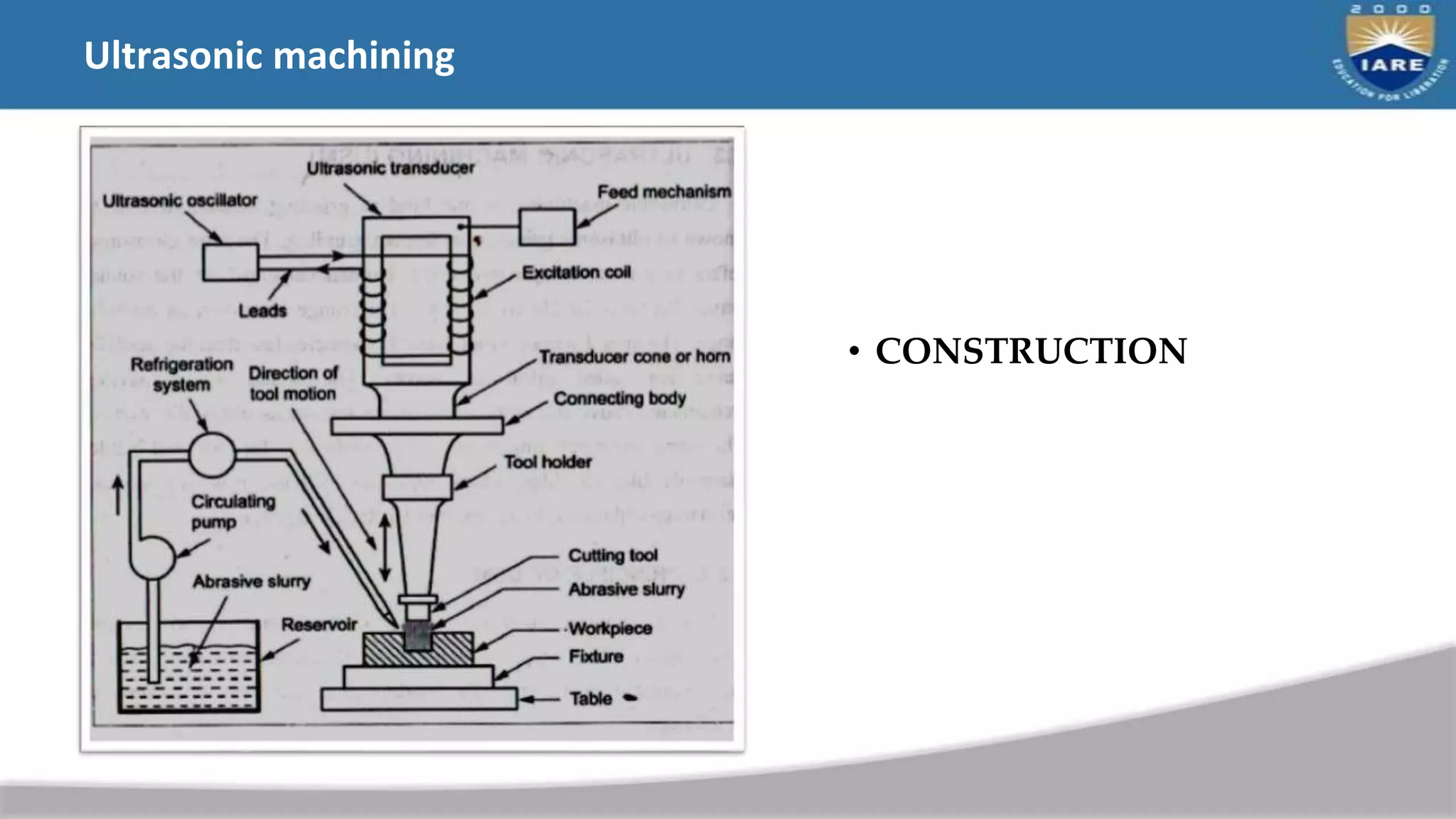

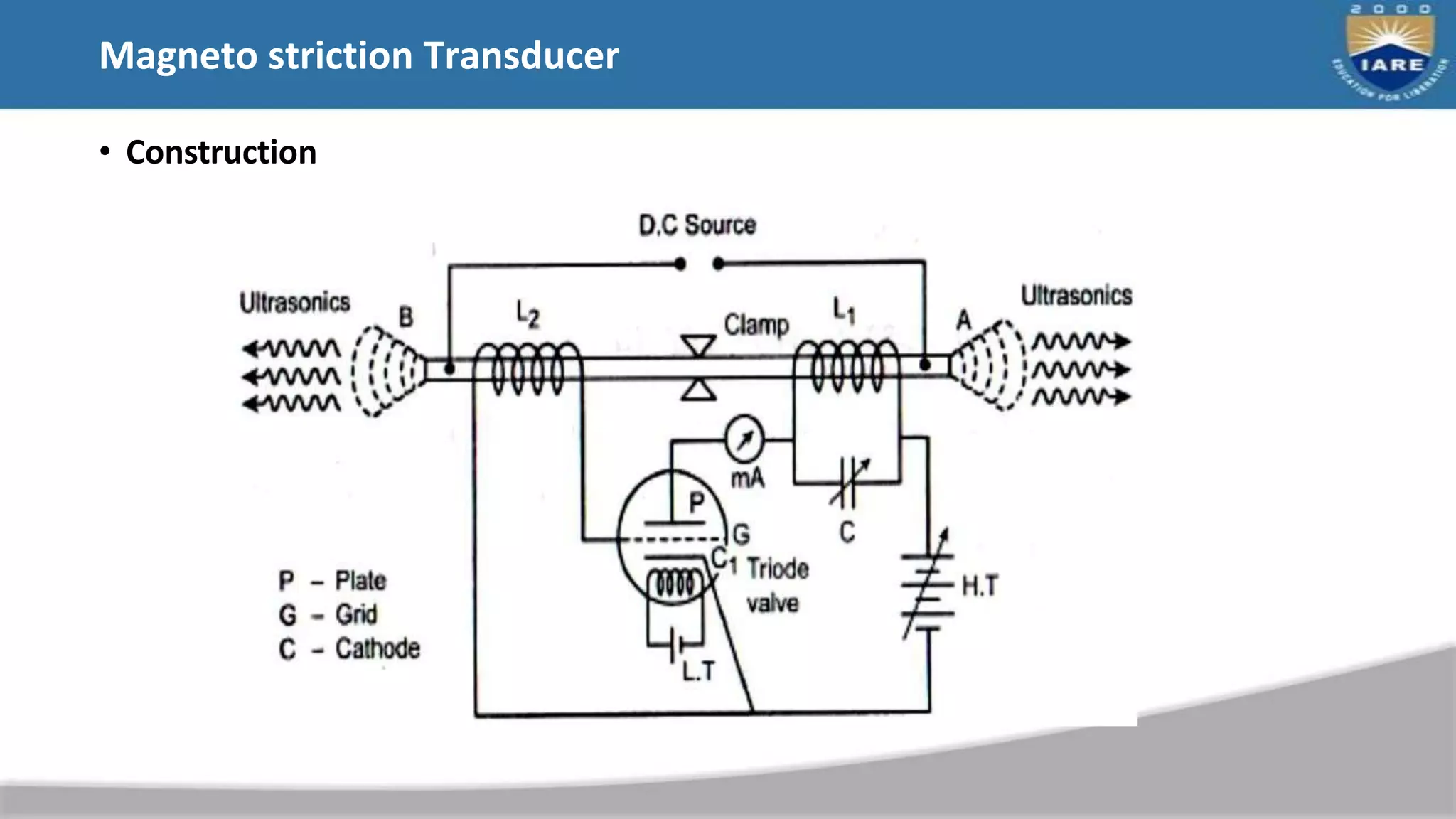

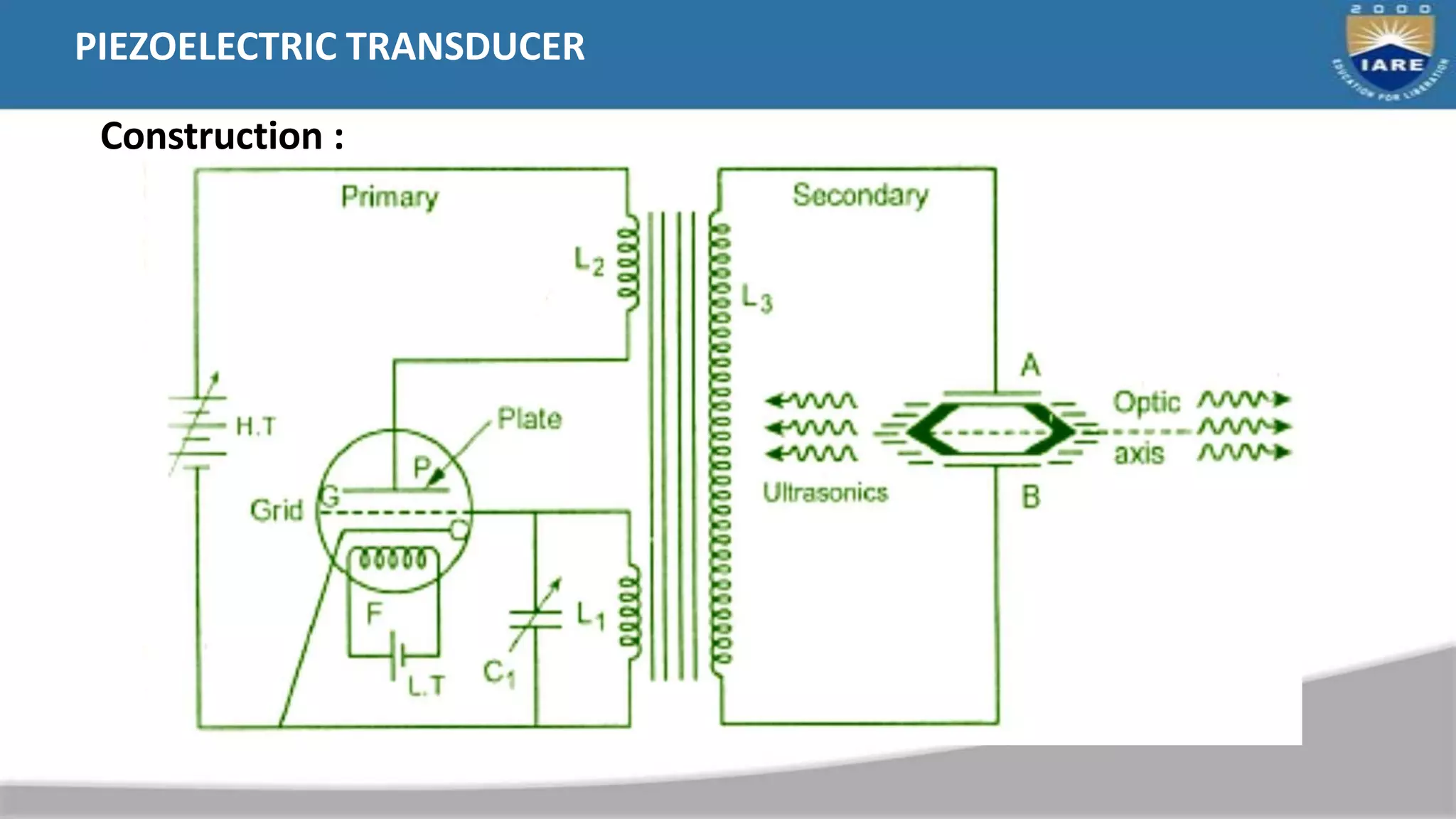

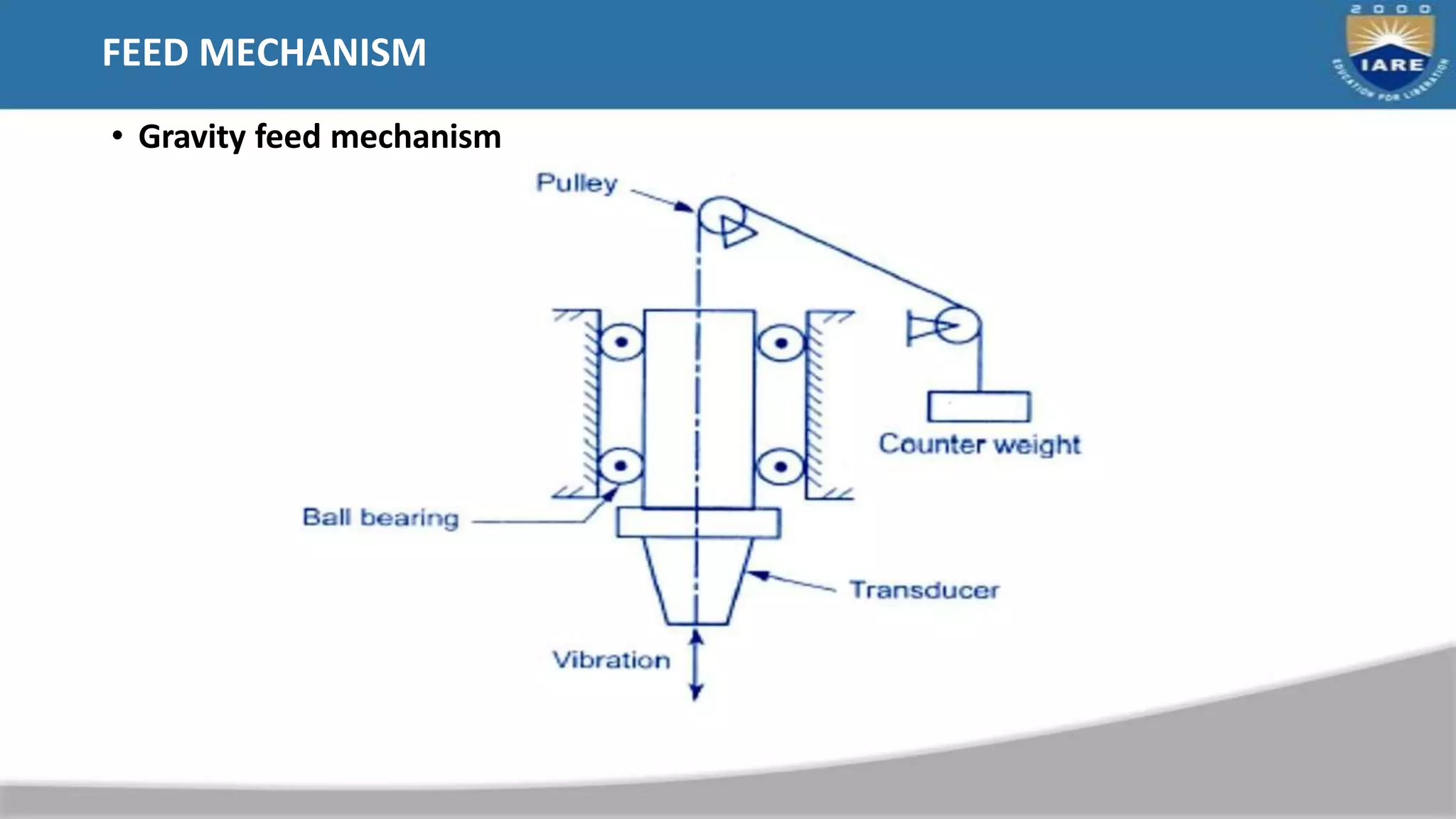

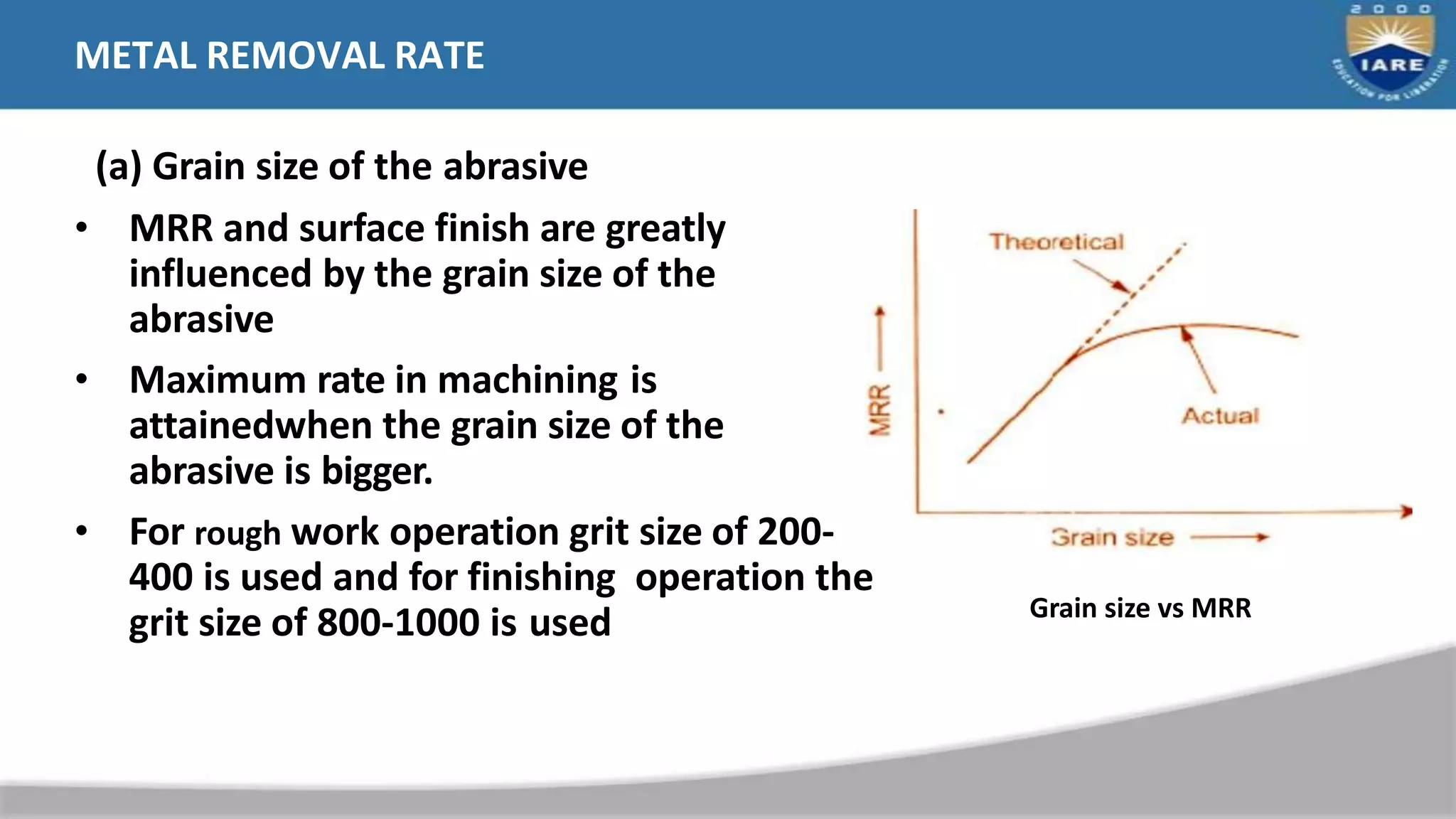

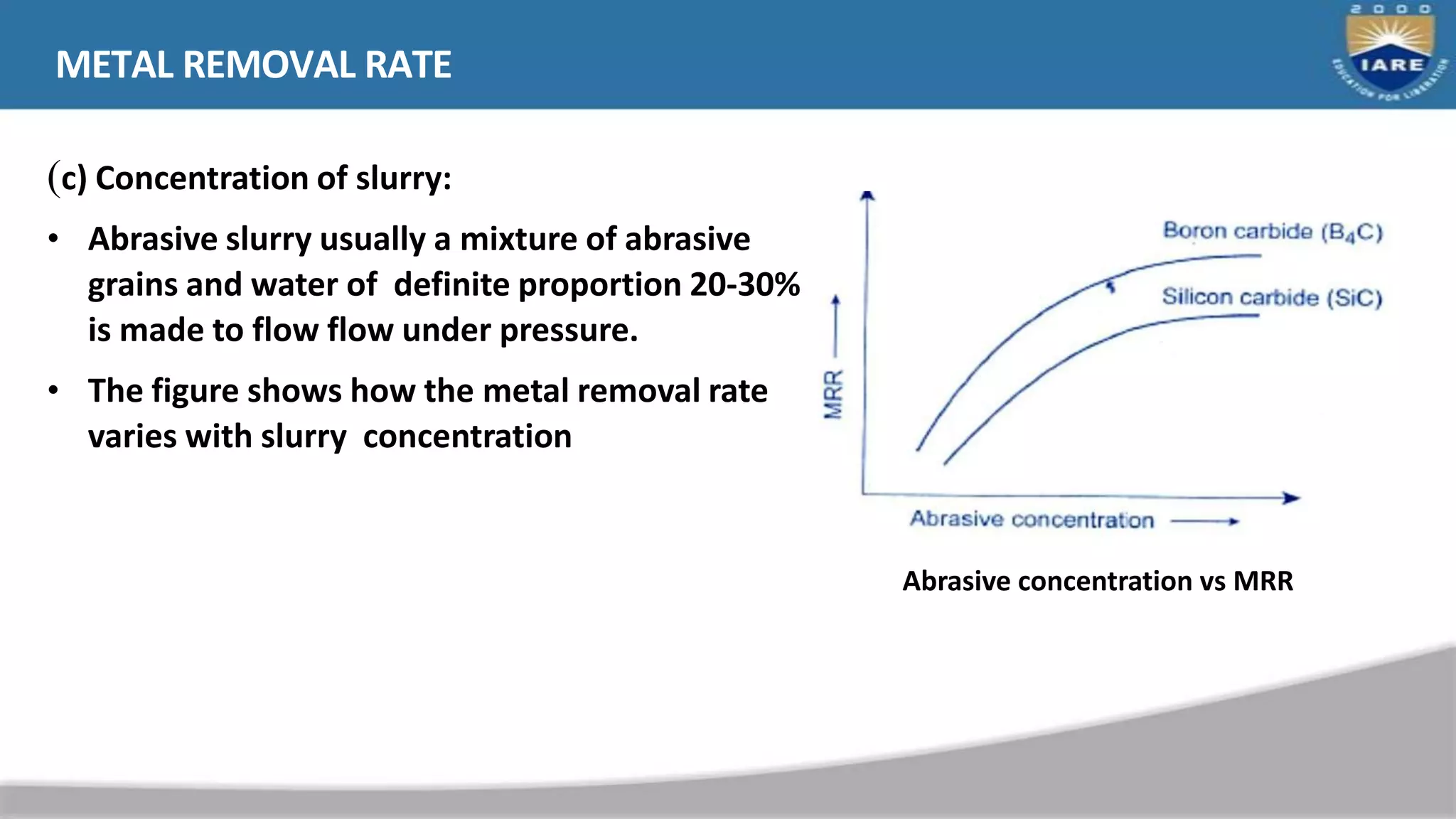

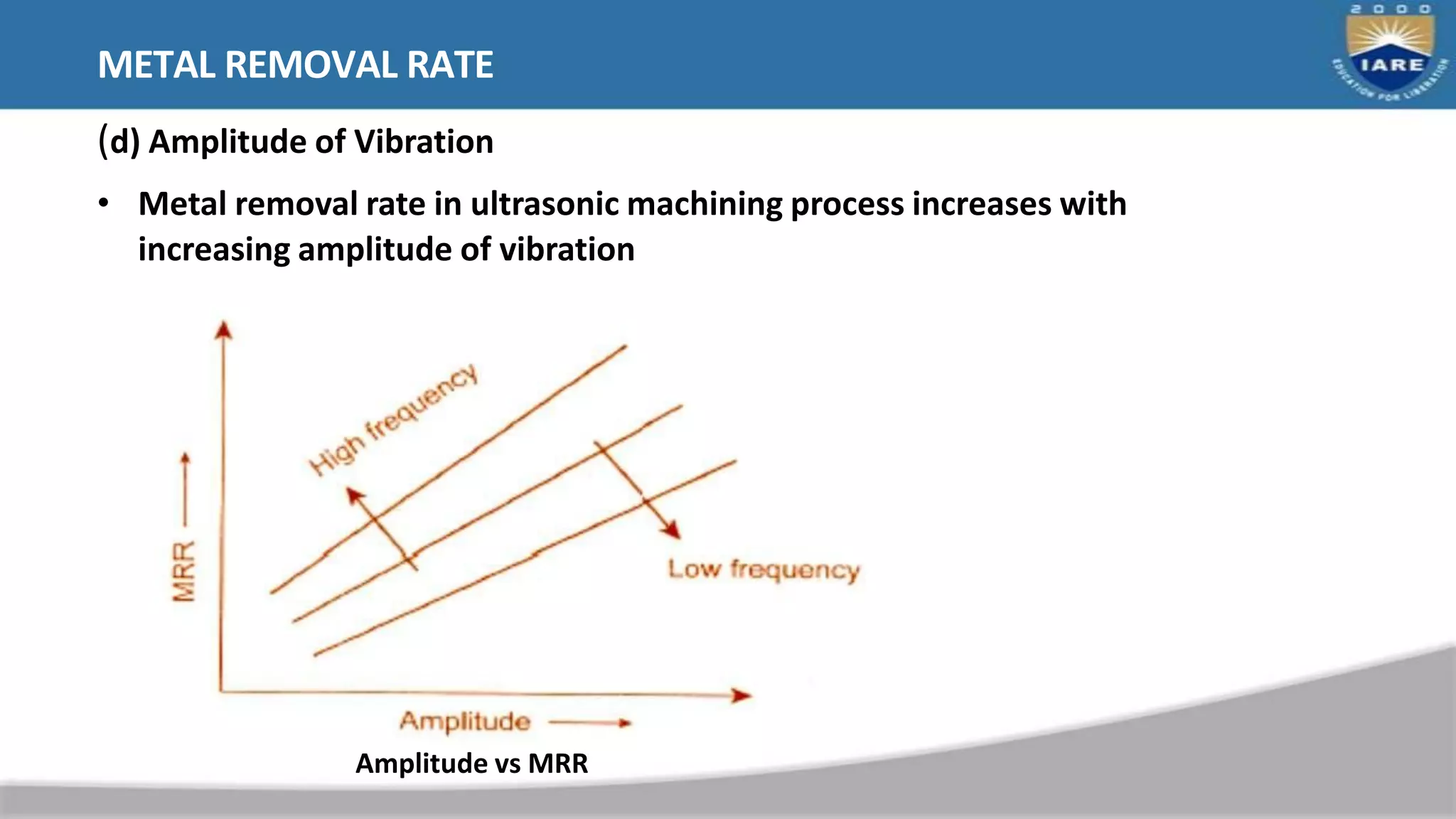

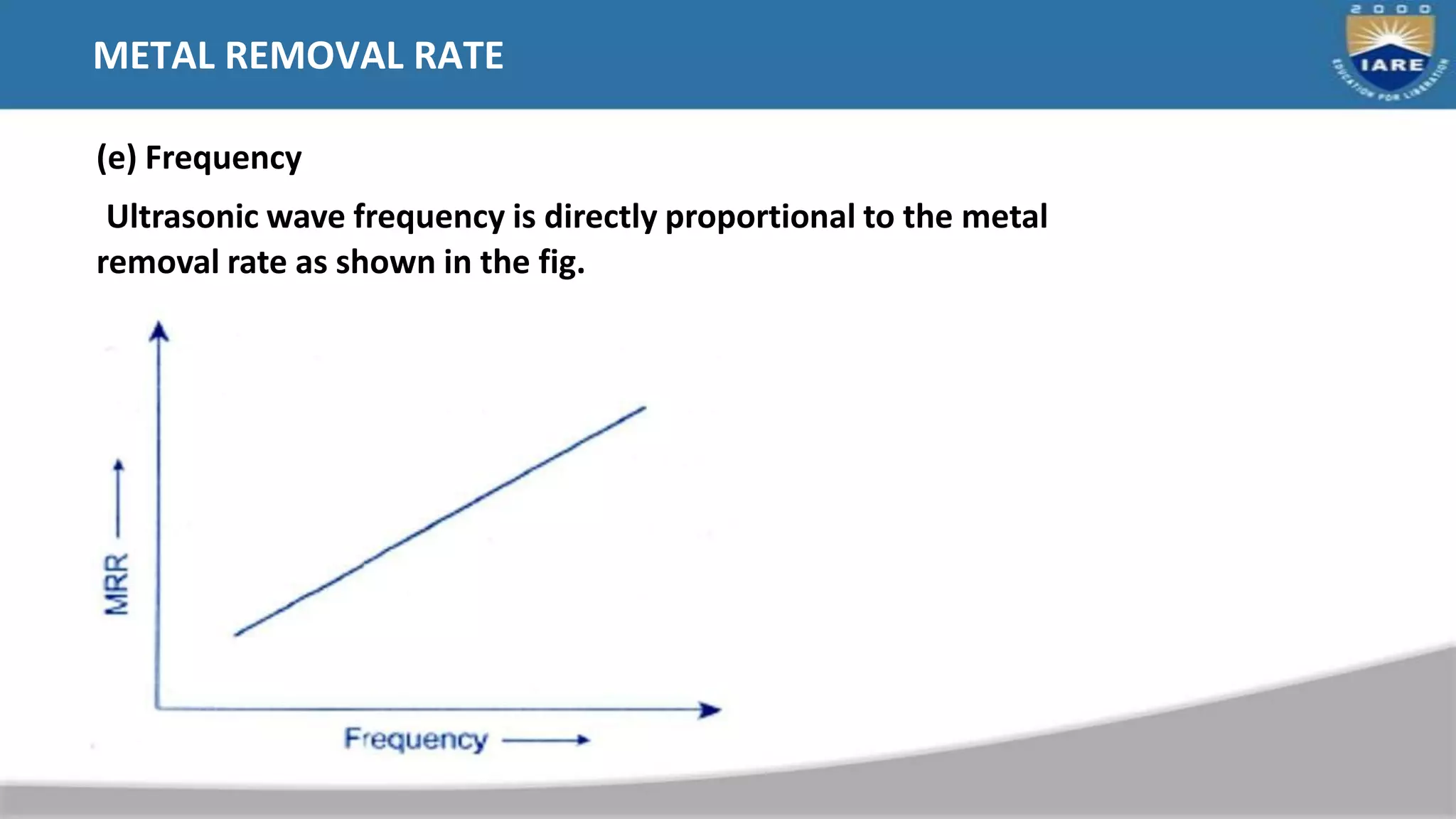

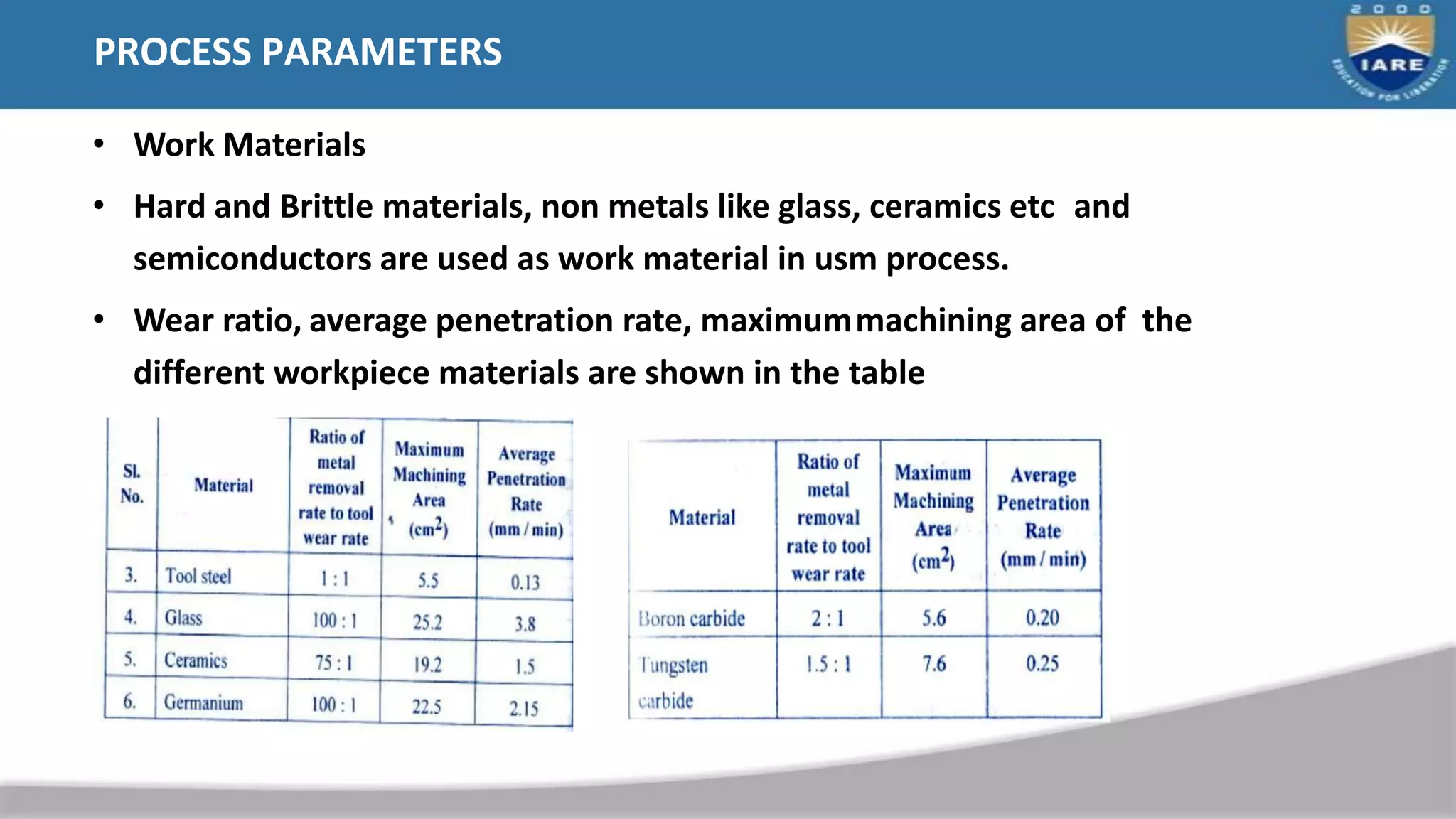

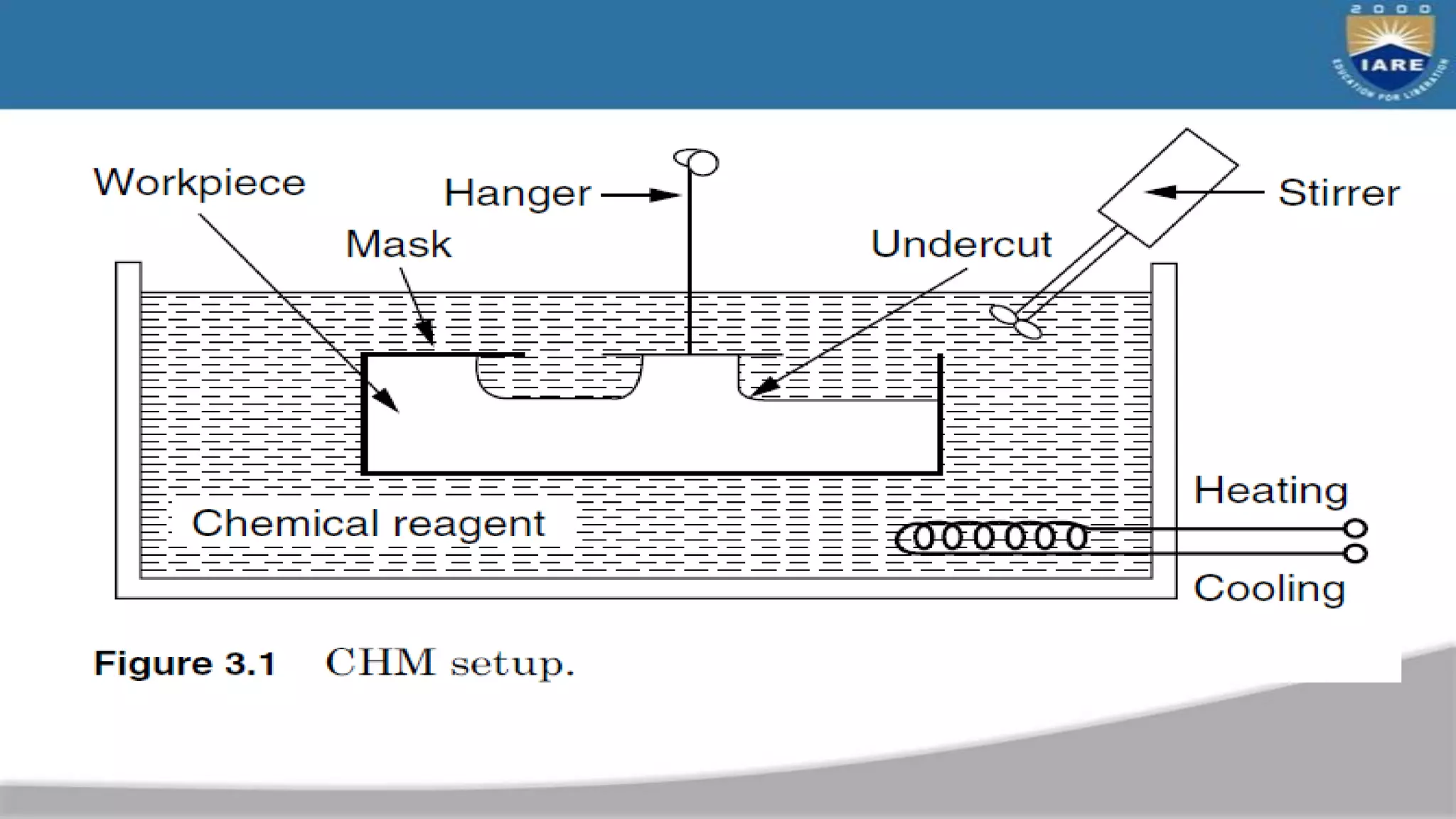

This document provides information about an Unconventional Machining Processes course. It includes the course code, regulation, instructor details, course outcomes, modules, and learning outcomes. Specifically, it outlines Module I which provides an introduction to unconventional machining processes, including ultrasonic machining. It discusses the history, principles, setup, mechanisms, materials used, applications, and limitations of ultrasonic machining.