More Related Content

PPTX

About the TRANSFORMERS and its working principle PPTX

Auto Transformers in Electrical Machines PPTX

1909023_EEE291_Three Phase Transformer.pptx PPTX

Transformer presentaton the the working principal.pptx PPT

B tech ee ii_ eee_ u-4_ transformer & electrical wiring_dipen patel PPTX

PPTX

Transformer its types ,working,basic principle.pptx PPT

OPERATION AND MAINTAINANCE OF DISTRIBUTION TRANSFORMER AND PREVENTIOMOF FAILURE Similar to Abb power transformer detail presentation.ppt

PDF

Module3- Transformer (1).pdf PPTX

ch4-transformer-and-dc-motor for ug .pptx PPTX

PPTX

PPT

PPTX

Transformers and its Types PDF

Transformers devices and its efficiency of it PPT

(2)OPERATING PRINCIPLES.ppt FOR STUDY PU PPTX

Transformers and common types of transformer PPTX

Transformer types presentation.................................................. PPTX

UNIT - II Transformers.pptx PPTX

UNIT - II Transformers.pptx PDF

PPTX

PPT

OPERATING PRINCIPLES OF TRANSFORMER AND CONSTRUCTION.ppt PPTX

PDF

Internship report report on harmonic analysis of transformer, internship repo... PPTX

Machines 1 2024-25, single transformers.pptx PDF

General concepts, construction and design of transformer PPTX

Recently uploaded

PDF

NS unit wise unit wise 1 -5 so prepare,. PDF

Plasticity and Structure of Soil/Atterberg Limits.pdf PPTX

Presentation-WPS Office.pptx afgouvhyhgfccf PDF

Microeconomics Theory and Market Structure.pdf PPTX

Optimizing the ELBO Objective: A Comparative Study of RNN, LSTM, and GRU Arch... PPTX

Optimum mesh size for various fishing gears by B2B.pptx PPTX

Batch-1(End Semester) Student Of Shree Durga Tech. PPT.pptx PDF

Rajesh Prasad- Brief Profile with educational, professional highlights PDF

engineering management chapter 5 ppt presentation PDF

PROBLEM SLOVING AND PYTHON PROGRAMMING UNIT 3.pdf PPTX

Why Most SAP PM Implementations Fail — And How High-Reliability Plants Fix It PPTX

Every Plant Has a Weak Link: How AI CMMS Exposes Hidden Reliability Risks PPTX

unit v awp IN ANTENNA AND WAVE PROP IN JNTUH PDF

Industrial Tools Manufacturers In India : Torso Tools PDF

MoD_2.pptx solid rockets of the rocket.pdf PPTX

A professional presentation on Cosmos Bank Heist PPTX

ME3592 - Metrology and Measurements - Unit - 1 - Lecture Notes PDF

DAA Lab Manual ssit -kavya r.pdf or Digital Design and Analysis of Algorithm ... PDF

(en/zhTW) Heterogeneous System Architecture: Design & Performance PDF

Computer Network Lab Manual ssit -kavya r.pdf or Computer Network Lab Manual ... Abb power transformer detail presentation.ppt

- 1.

- 2.

- 3.

- 4.

©

ABB

Power

Technology

1_114Q07-

4

-

Fundamental considerations

Staticdevice whose function is to transfer

electrical energy from one circuit to another

whose common link is a magnetic flux.

The current and voltage characteristics of the

incoming energy are modified in the output

Construction: Magnetic core made of stacked

sheets of ferromagnetic material and two coils

(B1, B2) wounded over the former.

G Z

B1 B2

- 5.

©

ABB

Power

Technology

1_114Q07-

5

-

Fundamental considerations

G Z

B1B2

Operation: We connect an a.c. generator at B1 and close B2

through an impedance Z.

B1 generates a flux owing to the current. This is a variable one hence

it induces a voltage in B2 which in time generates a current in the

secondary circuit.

It is only possible with alternating current (a flux variation is needed)

The circuit connected to B1 is named primary and the one

connected to B2 is named secondary

The related V and I characteristics are named as well primary and

secondary characteristics.

- 6.

©

ABB

Power

Technology

1_114Q07-

6

-

Fundamental relationships

Primaryenergy Secondary energy

Hence Primary Power Secondary Power

If the transformer is single phase U1 I1 U2 I2

And with three phase √3 U1 I1 √3 U2 I2

At both cases hence U1/ U2 I2 / I1

On the other hand it is known that Voltage in a coil is proportional to

the generated flux and number of turns

U1= k1 n1 and U2= k1 n2

From where it is inferred:

U1 / U2 = n1 / n2 and I2 / I1 = n1 / n2

The ratio n1 / n2 is called Transformation Ratio

- 7.

©

ABB

Power

Technology

1_114Q07-

7

-

We havethen:

U1 / U2 = r1

I1 / I2 = 1 / r1

The former statements are true in an ideal transformer which complies

with the following

No reluctance at the magnetic circuit

No resistance at the windings

No histeresys, eddy-current or I2R losses

No leakage flux

Although this is not accomplished in a real case, all formerly said is

useful to understand the performance of a transformer and to obtain

some approximate values for an elementary calculation

Fundamental relationships

- 8.

©

ABB

Power

Technology

1_114Q07-

8

-

From:

U1 I1= U2 I2

It is deduced that:

The winding with higher voltage must stand lesser current and

conversely the lesser the voltage the higher the current

On the other hand from:

I1 n1 = I2 n2

it is deduced that:

The winding with higher current will be the one with bigger cross

section but lesser number of turns

Fundamental relationships

- 9.

©

ABB

Power

Technology

1_114Q07-

9

-

Power transformer function

Transmission of electrical energy is cheaper as far as the transmission

voltage is raised

let´s have a power P to transmit with a voltage U and a current I.

Losses will be:

Pr = R I²

If voltage is raised to nU, current, for the same power, will be

reduced to I/n, hence losses in that case will be:

Pr = R I² / n²

They are hence reduced by the square of the ratio of voltage

raising.

Or for the same losses the cross section of the wire can be reduced,

so is the cost of the line.

On the other hand electrical energy is easier and safer to use when

handled at the lowest voltage.

- 10.

©

ABB

Power

Technology

1_114Q07-

10

-

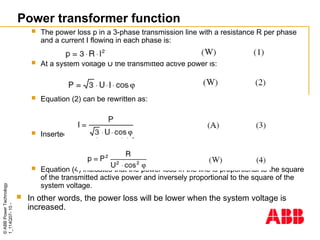

The powerloss p in a 3-phase transmission line with a resistance R per phase

and a current I flowing in each phase is:

At a system voltage U the transmitted active power is:

Equation (2) can be rewritten as:

Inserted in the equation (1) gives:

Equation (4) indicates that the power loss in the line is proportional to the square

of the transmitted active power and inversely proportional to the square of the

system voltage.

In other words, the power loss will be lower when the system voltage is

increased.

Power transformer function

- 11.

©

ABB

Power

Technology

1_114Q07-

11

-

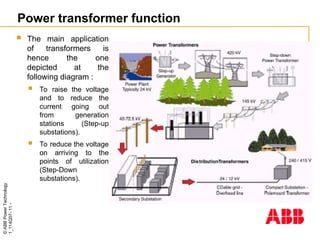

The mainapplication

of transformers is

hence the one

depicted at the

following diagram :

To raise the voltage

and to reduce the

current going out

from generation

stations (Step-up

substations).

To reduce the voltage

on arriving to the

points of utilization

(Step-Down

substations).

Power transformer function

- 12.

- 13.

©

ABB

Power

Technology

1_114Q07-

13

-

Main characteristics ofa Power Transformer

When choosing a transformer it is necessary to define:

Type of transformer

Transformation ratio

Insulation Class

Rated output

Connection

Also it is necessary to establish:

Voltage regulation

Type of cooling

Accessories

- 14.

- 15.

- 16.

©

ABB

Power

Technology

1_114Q07-

16

-

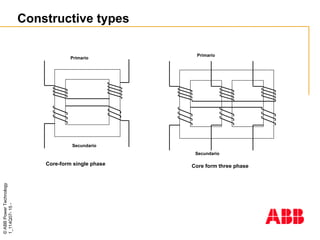

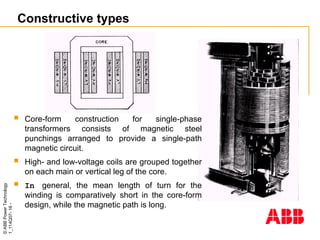

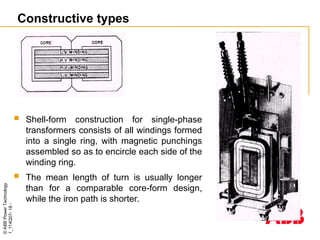

Constructive types

Core-formconstruction for single-phase

transformers consists of magnetic steel

punchings arranged to provide a single-path

magnetic circuit.

High- and low-voltage coils are grouped together

on each main or vertical leg of the core.

In general, the mean length of turn for the

winding is comparatively short in the core-form

design, while the magnetic path is long.

- 17.

- 18.

©

ABB

Power

Technology

1_114Q07-

18

-

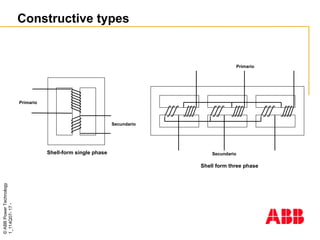

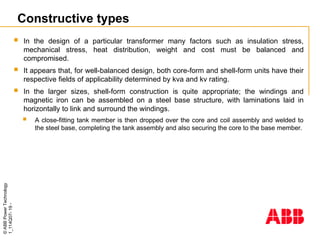

Constructive types

Shell-formconstruction for single-phase

transformers consists of all windings formed

into a single ring, with magnetic punchings

assembled so as to encircle each side of the

winding ring.

The mean length of turn is usually longer

than for a comparable core-form design,

while the iron path is shorter.

- 19.

©

ABB

Power

Technology

1_114Q07-

19

-

Constructive types

Inthe design of a particular transformer many factors such as insulation stress,

mechanical stress, heat distribution, weight and cost must be balanced and

compromised.

It appears that, for well-balanced design, both core-form and shell-form units have their

respective fields of applicability determined by kva and kv rating.

In the larger sizes, shell-form construction is quite appropriate; the windings and

magnetic iron can be assembled on a steel base structure, with laminations laid in

horizontally to link and surround the windings.

A close-fitting tank member is then dropped over the core and coil assembly and welded to

the steel base, completing the tank assembly and also securing the core to the base member.

- 20.

- 21.

- 22.

©

ABB

Power

Technology

1_114Q07-

22

-

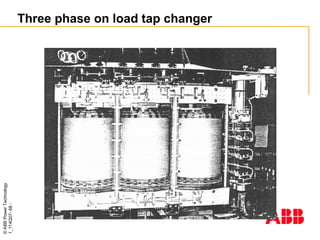

Single phase vs.Three phase banks

A three-phase power transformation can be accomplished either by using a three-phase

transformer unit, or by inter-connecting three single-phase units to form a three-phase bank.

The three-phase unit has advantages of greater efficiency, smaller size, and less cost when

compared with a bank having equal kva capacity made up of three single-phase units.

When three single-phase units are used in a bank, it is possible to purchase and install a

fourth unit at the same location as an emergency spare.

This requires only 33 percent additional investment to provide replacement capacity, whereas 100

percent additional cost would be required to provide complete spare capacity for a three-phase unit.

However, transformers have a proven reliability higher than most other elements of a power system,

and for this reason the provision of immediately available spare capacity is now considered less

important than it once was.

- 23.

©

ABB

Power

Technology

1_114Q07-

23

-

Single phase vs.Three phase banks

Three-phase units are quite generally used in the highest of circuit

ratings, with no on-the-spot spare transformer capacity provided.

In these cases parallel or interconnected circuits of the system may

provide emergency capacity, or, for small and medium size

transformers, portable substations can provide spare capacity on short

notice.

If transportation or rigging facilities should not be adequate to handle

the required transformer capacity as a single unit, a definite reason of

course develops for using three single-phase units.

- 24.

- 25.

- 26.

©

ABB

Power

Technology

1_114Q07-

26

-

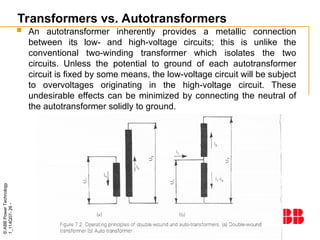

Transformers vs. Autotransformers

An autotransformer inherently provides a metallic connection

between its low- and high-voltage circuits; this is unlike the

conventional two-winding transformer which isolates the two

circuits. Unless the potential to ground of each autotransformer

circuit is fixed by some means, the low-voltage circuit will be subject

to overvoltages originating in the high-voltage circuit. These

undesirable effects can be minimized by connecting the neutral of

the autotransformer solidly to ground.

- 27.

©

ABB

Power

Technology

1_114Q07-

27

-

Transformers vs. Autotransformers

The autotransformer has advantages of:

lower cost,

higher efficiency

better regulation

It has disadvantages including:

low reactance which may make it subject to excessive short-circuit currents

the arrangement of taps is more complicated

the low- and high-voltage circuits cannot be isolated

the two circuits must operate with no angular phase displacement unless a zig-zag

connection is introduced.

The advantages of lower cost and improved efficiency become less apparent as

the transformation ratio increases, so that autotransformers for power purposes

are usually used for low transformation ratios, rarely exceeding 2 to 1.

- 28.

©

ABB

Power

Technology

1_114Q07-

28

-

Transformers vs. Autotransformers

Three-phase autotransformers for power service are usually star-star

connected with the neutral grounded, and in most of these cases it is

desirable to have a third winding on the core delta-connected so as to

carry the third harmonic component of exciting current.

This winding could be very small in capacity if it were required to carry

only harmonic currents, but its size is increased by the requirement that it

carry high currents during system ground faults.

A widely used rule sets the delta-winding rating at 35 percent of the

autotransformer equivalent two-winding kva rating (not circuit kva rating).

Since it is necessary in most cases to have a delta-connected tertiary

winding, it is often advantageous to design this winding so that load

can be taken from it. This results in a three-winding autotransformer

with terminals to accommodate three external circuits.

- 29.

- 30.

©

ABB

Power

Technology

1_114Q07-

30

-

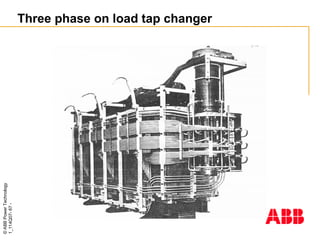

Transformation ratio

Primaryvoltage : The most usual value of the voltage at the point of

the network where the transformer is going to be connected

When this voltage is expected to vary it could be necessary that the

transformer is equipped with an on load tap changer

Secondary voltage: The desired value at the secondary network

where the transformer will be connected.

- 31.

©

ABB

Power

Technology

1_114Q07-

31

-

Transformation ratio andvoltage drop

The voltage ratio of a transformer is normally specified in no load

condition and is directly proportional to the ratio of the number of

turns in the windings.

When the transformer is loaded, the voltage on the secondary

terminals changes from that in no load condition, depending on

the angle φ between the voltage on the secondary terminals of the

transformer U2 and the secondary current I2

the value of the secondary current I2

the short-circuit impedance of the transformer Z and its active

and reactive components, r and ±jx respectively

- 32.

©

ABB

Power

Technology

1_114Q07-

32

-

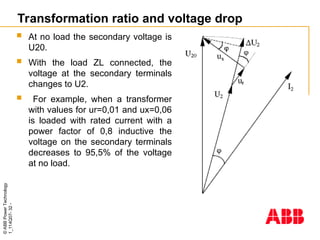

Transformation ratio andvoltage drop

At no load the secondary voltage is

U20.

With the load ZL connected, the

voltage at the secondary terminals

changes to U2.

For example, when a transformer

with values for ur=0,01 and ux=0,06

is loaded with rated current with a

power factor of 0,8 inductive the

voltage on the secondary terminals

decreases to 95,5% of the voltage

at no load.

- 33.

©

ABB

Power

Technology

1_114Q07-

33

-

Transformation ratio andvoltage drop

Users and installation planners are recommended to take the

variation of the secondary voltage during loading into account when

specifying the transformer data.

This may be especially important for example in a case where a

large motor represents the main load of the transformer.

The highly inductive starting current of the motor may then be

considerably higher than the rated current of the transformer.

Consequently there may be a considerable voltage drop through the

transformer.

If the feeding power source is weak, this will contribute to an even

lower voltage on the secondary side of the transformer.

- 34.

©

ABB

Power

Technology

1_114Q07-

34

-

Short circuit impedance

Users have sometimes particular requirements regarding the short-circuit

impedance. Such requirements may be determined by:

parallel operation with existing units,

limitation of voltage drop,

limitation of short-circuit currents.

The transformer designer can meet the requirements in different ways:

The size of the core cross-section. A large cross-section gives a low

impedance and vice versa,

A tall transformer gives a low impedance and vice versa.

For each transformer there is, however, a smaller range which gives the

optimum transformer from an economic point of view, that is the lowest

sum of the manufacturing costs and the capitalised value of the losses.

- 35.

©

ABB

Power

Technology

1_114Q07-

35

-

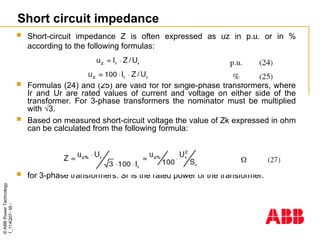

Short circuit impedance

Short-circuit impedance Z is often expressed as uz in p.u. or in %

according to the following formulas:

Formulas (24) and (25) are valid for for single-phase transformers, where

Ir and Ur are rated values of current and voltage on either side of the

transformer. For 3-phase transformers the nominator must be multiplied

with √3.

Based on measured short-circuit voltage the value of Zk expressed in ohm

can be calculated from the following formula:

for 3-phase transformers. Sr is the rated power of the transformer.

- 36.

- 37.

- 38.

©

ABB

Power

Technology

1_114Q07-

38

-

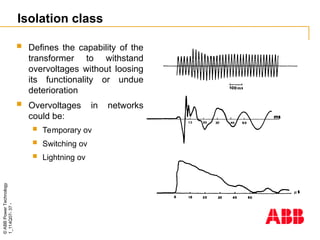

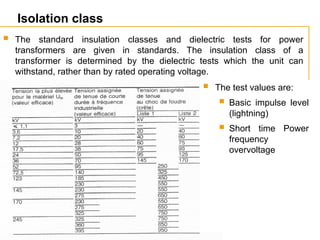

Isolation class

Thestandard insulation classes and dielectric tests for power

transformers are given in standards. The insulation class of a

transformer is determined by the dielectric tests which the unit can

withstand, rather than by rated operating voltage.

The test values are:

Basic impulse level

(lightning)

Short time Power

frequency

overvoltage

- 39.

- 40.

©

ABB

Power

Technology

1_114Q07-

40

-

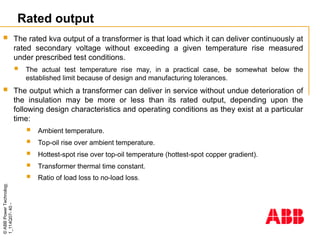

Rated output

Therated kva output of a transformer is that load which it can deliver continuously at

rated secondary voltage without exceeding a given temperature rise measured

under prescribed test conditions.

The actual test temperature rise may, in a practical case, be somewhat below the

established limit because of design and manufacturing tolerances.

The output which a transformer can deliver in service without undue deterioration of

the insulation may be more or less than its rated output, depending upon the

following design characteristics and operating conditions as they exist at a particular

time:

Ambient temperature.

Top-oil rise over ambient temperature.

Hottest-spot rise over top-oil temperature (hottest-spot copper gradient).

Transformer thermal time constant.

Ratio of load loss to no-load loss.

- 41.

©

ABB

Power

Technology

1_114Q07-

41

-

Loading Based onAmbient Temperature

Air-cooled oil-immersed transformers

built to meet established standards will

operate continuously with normal life

expectancy at rated kva and secondary

voltage, providing the ambient air

temperature averages no more than 30º

C throughout a 24-hour period with maximum air temperature never

exceeding 40 C. Water-cooled transformers are built to operate

continuously at rated output with ambient water temperatures averaging

25 C and never exceeding 30 C.

When the average temperature of the cooling medium is different from the

values above, a modification of the transformer loading may be made

according to Table 7.

In cases where the difference between maximum air temperature and

average air temperature exceeds 10 C, a new temperature that is 10 C below

the maximum should be used in place of the true average. The allowable

difference between maximum and average temperature for water-cooled

transformers is 5 C.

- 42.

©

ABB

Power

Technology

1_114Q07-

42

-

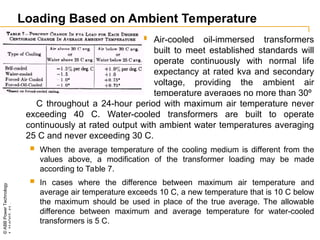

Loading Based onCapacity Factor

Transformer capacity factor (operating kva divided by rated kva)

averaged throughout a 24-hour period may be well below 100 percent,

and when this is true some compensating increase in maximum

transformer loading may be made. The percentage increase in maximum

loading as a function of capacity factor, based on a normal transformer

life expectancy, is given in Table 8.

- 43.

©

ABB

Power

Technology

1_114Q07-

43

-

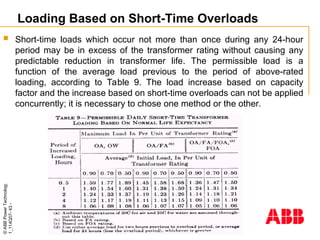

Loading Based onShort-Time Overloads

Short-time loads which occur not more than once during any 24-hour

period may be in excess of the transformer rating without causing any

predictable reduction in transformer life. The permissible load is a

function of the average load previous to the period of above-rated

loading, according to Table 9. The load increase based on capacity

factor and the increase based on short-time overloads can not be applied

concurrently; it is necessary to chose one method or the other.

- 44.

©

ABB

Power

Technology

1_114Q07-

44

-

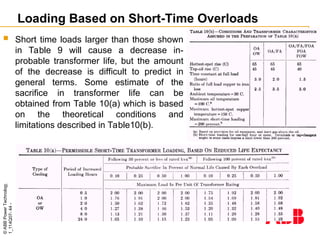

Loading Based onShort-Time Overloads

Short time loads larger than those shown

in Table 9 will cause a decrease in-

probable transformer life, but the amount

of the decrease is difficult to predict in

general terms. Some estimate of the

sacrifice in transformer life can be

obtained from Table 10(a) which is based

on the theoretical conditions and

limitations described in Table10(b).

- 45.

©

ABB

Power

Technology

1_114Q07-

45

-

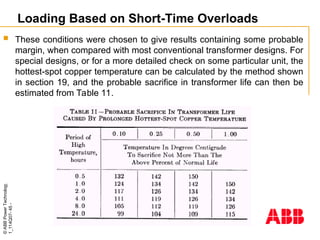

Loading Based onShort-Time Overloads

These conditions were chosen to give results containing some probable

margin, when compared with most conventional transformer designs. For

special designs, or for a more detailed check on some particular unit, the

hottest-spot copper temperature can be calculated by the method shown

in section 19, and the probable sacrifice in transformer life can then be

estimated from Table 11.

- 46.

©

ABB

Power

Technology

1_114Q07-

46

-

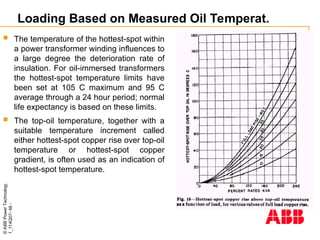

Loading Based onMeasured Oil Temperat.

The temperature of the hottest-spot within

a power transformer winding influences to

a large degree the deterioration rate of

insulation. For oil-immersed transformers

the hottest-spot temperature limits have

been set at 105 C maximum and 95 C

average through a 24 hour period; normal

life expectancy is based on these limits.

The top-oil temperature, together with a

suitable temperature increment called

either hottest-spot copper rise over top-oil

temperature or hottest-spot copper

gradient, is often used as an indication of

hottest-spot temperature.

- 47.

©

ABB

Power

Technology

1_114Q07-

47

-

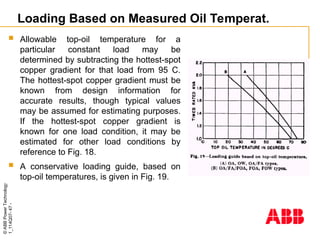

Loading Based onMeasured Oil Temperat.

Allowable top-oil temperature for a

particular constant load may be

determined by subtracting the hottest-spot

copper gradient for that load from 95 C.

The hottest-spot copper gradient must be

known from design information for

accurate results, though typical values

may be assumed for estimating purposes.

If the hottest-spot copper gradient is

known for one load condition, it may be

estimated for other load conditions by

reference to Fig. 18.

A conservative loading guide, based on

top-oil temperatures, is given in Fig. 19.

- 48.

©

ABB

Power

Technology

1_114Q07-

48

-

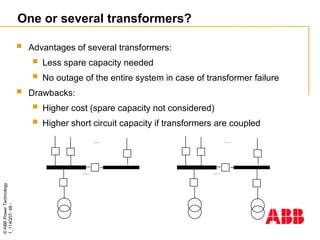

One or severaltransformers?

Advantages of several transformers:

Less spare capacity needed

No outage of the entire system in case of transformer failure

Drawbacks:

Higher cost (spare capacity not considered)

Higher short circuit capacity if transformers are coupled

......

......

......

......

- 49.

©

ABB

Power

Technology

1_114Q07-

49

-

Parallel operation oftransformers

When there are several transformers at the substation it is possible to couple

them or not.

On the other hand in transmission networks the transformers are always coupled.

Advantages: No outage when one of the transformers is disconnected

(providing there is capacity enough at the network)

Drawbacks: Higher short circuit capacity

Provisions to be taken before coupling:

Same transformer ratio

Matching connection group

Matching phase rotation direction

Short circuit voltage inversely proportional to rated output

Tap changing coordination

- 50.

- 51.

©

ABB

Power

Technology

1_114Q07-

51

-

Transformer connections

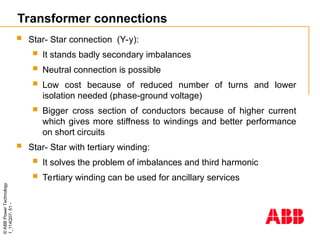

Star-Star connection (Y-y):

It stands badly secondary imbalances

Neutral connection is possible

Low cost because of reduced number of turns and lower

isolation needed (phase-ground voltage)

Bigger cross section of conductors because of higher current

which gives more stiffness to windings and better performance

on short circuits

Star- Star with tertiary winding:

It solves the problem of imbalances and third harmonic

Tertiary winding can be used for ancillary services

- 52.

©

ABB

Power

Technology

1_114Q07-

52

-

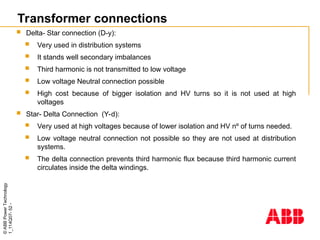

Delta- Starconnection (D-y):

Very used in distribution systems

It stands well secondary imbalances

Third harmonic is not transmitted to low voltage

Low voltage Neutral connection possible

High cost because of bigger isolation and HV turns so it is not used at high

voltages

Star- Delta Connection (Y-d):

Very used at high voltages because of lower isolation and HV nº of turns needed.

Low voltage neutral connection not possible so they are not used at distribution

systems.

The delta connection prevents third harmonic flux because third harmonic current

circulates inside the delta windings.

Transformer connections

- 53.

- 54.

- 55.

- 56.

©

ABB

Power

Technology

1_114Q07-

56

-

Voltage control

Themodern load tap changer had its beginning in 1925.

Since that time the development of more complicated transmission networks has

made tap changing under load more and more essential to control the in-phase

voltage of power transformers.

Tap-changing-under-load equipment is applied to power transformers:

to maintain a constant secondary voltage with a variable primary voltage;

to control the secondary voltage with a fixed primary voltage;.

Various types of tap-changing equipment and circuits are used depending

upon the voltage and kva.

Under-load-tap-changers are built for 8, 16, and 32 steps, with the trend in recent

years being toward the larger number of steps so as to give a finer degree of

regulation.

The usual range of regulation is plus 10 percent and minus 10 percent of the rated

line voltage, with plus and minus 71/2 percent and plus and minus 5 percent being

second and third, respectively, in popularity.

- 57.

©

ABB

Power

Technology

1_114Q07-

57

-

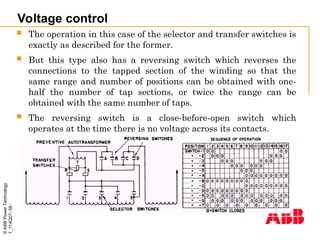

Voltage control

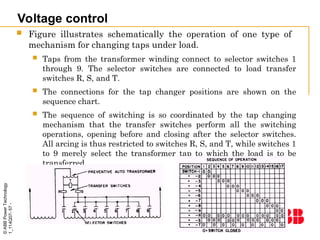

Figureillustrates schematically the operation of one type of

mechanism for changing taps under load.

Taps from the transformer winding connect to selector switches 1

through 9. The selector switches are connected to load transfer

switches R, S, and T.

The connections for the tap changer positions are shown on the

sequence chart.

The sequence of switching is so coordinated by the tap changing

mechanism that the transfer switches perform all the switching

operations, opening before and closing after the selector switches.

All arcing is thus restricted to switches R, S, and T, while switches 1

to 9 merely select the transformer tap to which the load is to be

transferred.

- 58.

©

ABB

Power

Technology

1_114Q07-

58

-

Voltage control

Whenthe tap changer is on odd-numbered positions, the

preventive auto-transformer is short-circuited.

On all even- numbered positions, the preventive auto-

transformer bridges two transformer taps.

In this position, the relatively high reactance of the preventive

auto-transformer to circulating currents between adjacent taps

prevents damage to the transformer winding, while its relatively

low impedance to the load current permits operation on this

position to obtain voltages midway between the transformer

taps.

- 59.

©

ABB

Power

Technology

1_114Q07-

59

-

Voltage control

Theoperation in this case of the selector and transfer switches is

exactly as described for the former.

But this type also has a reversing switch which reverses the

connections to the tapped section of the winding so that the

same range and number of positions can be obtained with one-

half the number of tap sections, or twice the range can be

obtained with the same number of taps.

The reversing switch is a close-before-open switch which

operates at the time there is no voltage across its contacts.

- 60.

©

ABB

Power

Technology

1_114Q07-

60

-

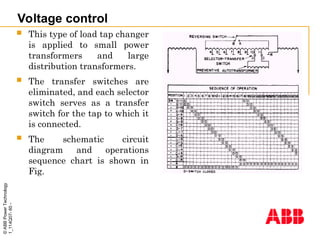

Voltage control

Thistype of load tap changer

is applied to small power

transformers and large

distribution transformers.

The transfer switches are

eliminated, and each selector

switch serves as a transfer

switch for the tap to which it

is connected.

The schematic circuit

diagram and operations

sequence chart is shown in

Fig.

- 61.

- 62.

©

ABB

Power

Technology

1_114Q07-

62

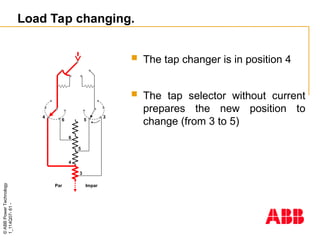

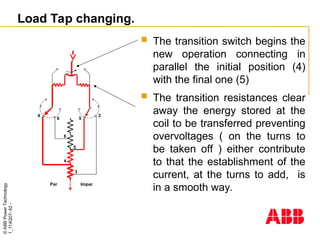

-

3

3

6

5

5

6

4

4

Impar

Par

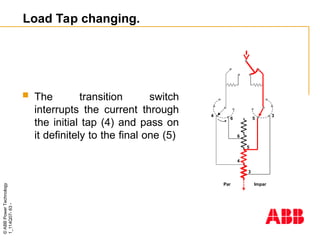

The transitionswitch begins the

new operation connecting in

parallel the initial position (4)

with the final one (5)

The transition resistances clear

away the energy stored at the

coil to be transferred preventing

overvoltages ( on the turns to

be taken off ) either contribute

to that the establishment of the

current, at the turns to add, is

in a smooth way.

Load Tap changing.

- 63.

- 64.

- 65.

- 66.

- 67.

- 68.

- 69.

- 70.

- 71.

- 72.

- 73.

©

ABB

Power

Technology

1_114Q07-

73

-

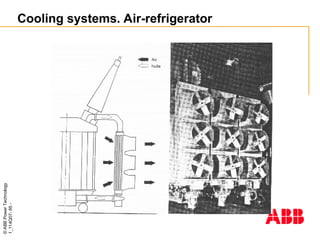

Types of cooling

Cooling is needed to transfer the heat produced by losses so as

not to damage isolation

Two main types of isolation exist:

Dry Transformers, air refrigerated

Oil immersed Transformers

In Substations the most used is the second one

Dry type are only used for low output and when fire hazard is a big

concern

- 74.

©

ABB

Power

Technology

1_114Q07-

74

-

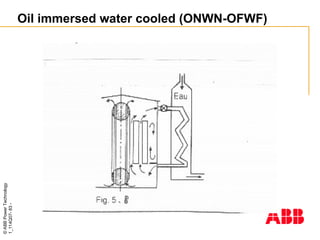

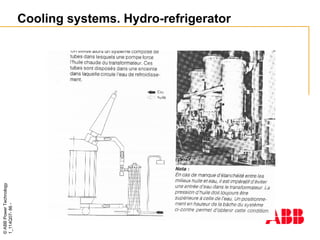

Types of cooling

Several types of cooling are possible with oil immersed

transformers:

Oil immersed Self cooled (ONAN)

Oil Immersed Self Cooled/Forced-Air Cooled (ONAF)

Oil immersed Forced cooled/Forced air cooled (OFAF)

Oil immersed Water cooled (ONWN-OFWF)

- 75.

©

ABB

Power

Technology

1_114Q07-

75

-

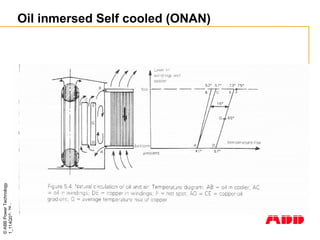

Oil inmersed Selfcooled (ONAN)

In this type of transformer the insulating oil circulates by natural convection

within a tank having either smooth sides, corrugated sides, integral tubular

sides, or detachable radiators.

Smooth tanks are used for small distribution transformers but because the losses

increase more rapidly than the tank surface area as kva capacity goes up, a smooth

tank transformer larger than 50 kva would have to be abnormally large to provide

sufficient radiating surface.

Integral tubular-type construction is used up to about 3000 kva and in some cases

to larger capacities, though shipping restrictions usually limit this type of

construction at the larger ratings.

Above 3000 kva detachable radiators are usually supplied.

Transformers rated 46 kv and below may also be filled with Inerteen fire-proof

insulating liquid, instead of with oil.

The ONAN transformer is a basic type, and serves as a standard for rating

and pricing other types.

- 76.

- 77.

©

ABB

Power

Technology

1_114Q07-

77

-

Oil-Imm Self-Cooled/Forced-Air Cooled(ONAF)

This type of transformer is basically an ONAN unit with the addition of fans to

increase the rate of heat transfer from the cooling surfaces, thereby increasing the

permissible transformer output.

The ONAF transformer is applicable in situations that require short-time peak loads to

be carried recurrently, without affecting normal expected transformer life.

This transformer may be purchased with fans already installed, or it may be purchased with

the option of adding fans later.

The higher kva capacity attained by the use of fans may be calculated as follows :

For 2500 kva (OA) and below: kva (FA)=l.l5Xkva(OA).

For 2501 to 9999 kva (OA) single-phase or 11 999 kva (OA) three-phase : kva (FA) = 1.25

X kva (OA).

For 10 000 kva (OA) single-phase and 12 000 kva (OA) three-phase, and above : kva (FA)

= 1.333Xkva (OA). (22)

These ratings are standardized, and are based on a hottest-spot copper temperature of 65

degrees C above 30 degrees C average ambient.

- 78.

- 79.

©

ABB

Power

Technology

1_114Q07-

79

-

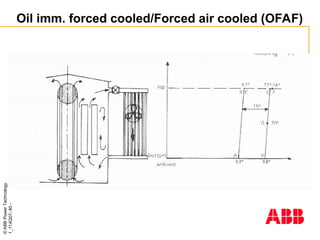

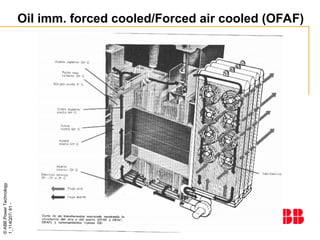

Oil imm. forcedcooled/Forced air cooled (OFAF)

The rating of an oil-immersed transformer may be increased from its OA

rating by the addition of some combination of fans and oil pumps.

Such transformers are normally built in the range 10 000 kva (OA) single-

phase or 12 000 kva (OA) three-phase, and above.

Increased ratings are defined as two steps, 1.333 and 1.667 times the OA rating

respectively.

Automatic controls responsive to oil temperature are normally used to start the

fans and pumps in a selected sequence as transformer loading increases.

A variation of this is a type of transformer which is intended for use only

when both oil pumps and fans are operating, under which condition any load

up to full rated kva may be carried.

Some designs are capable of carrying excitation current with no fans or pumps in

operation, but this is not universally true. Heat transfer from oil to air is

accomplished in external oil-to-air heat exchangers.

- 80.

- 81.

- 82.

©

ABB

Power

Technology

1_114Q07-

82

-

Oil immersed watercooled (ONWN-OFWF)

OW-Oil-Immersed Water-Cooled

In this type of water-cooled transformer, the cooling water runs

through coils of pipe which are in contact with the insulating oil of

the transformer.

The oil flows around the outside of these pipe coils by natural

convection, thereby effecting the desired heat transfer to the cooling

water. This type has no self-cooled rating.

FOW-Oil-Immersed Forced-Oil-Cooled With Forced-Water

Cooler-External oil-to-water heat exchangers are used in this type

of unit to transfer heat from oil to cooling water.

- 83.

- 84.

- 85.

- 86.

- 87.

- 88.

- 89.

- 90.

- 91.

©

ABB

Power

Technology

1_114Q07-

91

-

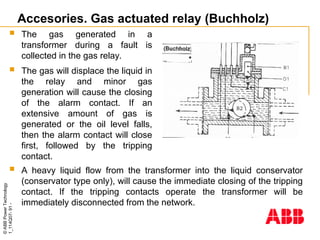

Accesories. Gas actuatedrelay (Buchholz)

A heavy liquid flow from the transformer into the liquid conservator

(conservator type only), will cause the immediate closing of the tripping

contact. If the tripping contacts operate the transformer will be

immediately disconnected from the network.

The gas generated in a

transformer during a fault is

collected in the gas relay.

The gas will displace the liquid in

the relay and minor gas

generation will cause the closing

of the alarm contact. If an

extensive amount of gas is

generated or the oil level falls,

then the alarm contact will close

first, followed by the tripping

contact.

- 92.

©

ABB

Power

Technology

1_114Q07-

92

-

Accesories. Gas actuatedrelay (Buchholz)

Operation of some protective equipment such as gas relay or

differential relay does not always mean that the transformer is

damaged.

The gas relay can operate for example when:

An air bubble has been left under the transformer cover. An air bubble is

colourless and odourless.

A short-circuit current has passed the transformer. No gas bubbles.

However if the gas has colour or smell, the transformer is damaged.

- 93.

- 94.

- 95.

- 96.

- 97.

- 98.

- 99.

©

ABB

Power

Technology

1_114Q07-

99

-

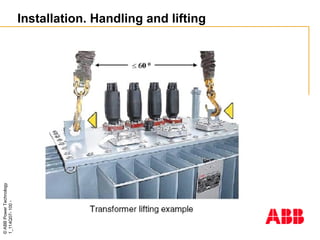

Installation. Handling andlifting

Only approved and suitable lifting equipment shall be used.

Use a forklift only on transport pallets or transformer bottom.

Do not apply load to corrugated fins or radiators and their supports.

Use the provided lifting lugs only.

When lifting a transformer with cable boxes on the cover, special

care must be taken.

When hydraulic jacks are used, only provided jacking points shall

be used, and in such a way that twisting forces on the transformer

tank are avoided.

- 100.

- 101.

- 102.

©

ABB

Power

Technology

1_114Q07-

102

-

Transport

The transformeris supplied filled with liquid and normally all

accessories fitted, except for the largest units. The radiators may be

dismantled during transport.

During transport the following should be considered:

Angle of tilting exceeding 10º must be specified in the contract,

Prevention of damage to bushings, corrugated panels or

radiators and accessories,

Larger transformers should preferably be positioned with the

longitudinal axis in the direction of movement,

Secure against movement by means of e.g. wooden blocks and

lashes,

Adapt vehicle speed to the road conditions,

Vehicle capacity shall be adequate for the transport weight of

the transformer,

- 103.

- 104.

- 105.

- 106.

- 107.

©

ABB

Power

Technology

1_114Q07-

107

-

Maintenance

Inspection andmaintenance during operation

Inspection during operation shall only be performed after taking

safety measures into consideration:

If there is a maximum indicator on the thermometer the

maximum temperature should be recorded,

Inspection for contamination, especially on bushings,

Inspection of surface condition,

Dehydrating breather. The silicagel shall be changed when

approx. 2/3 of the silica gel has changed from blue to red colour

(old type), or from pink to white, respectively. (Conservator type

only),

Inspection for liquid leakages.

For personal safety reasons, only a limited amount of maintenance

activities should be performed on the transformer when it is in

operation.

- 108.

©

ABB

Power

Technology

1_114Q07-

108

-

Maintenance

Inspection andmaintenance during downtime

Before starting maintenance work, the transformer has to be

disconnected from the network and earthed. When the

disconnectors have been opened, they shall be locked in open

position to prevent them inadvertently closing during maintenance

work.

Items to be considered are:

Bushing gaskets; if leaks occur, tightening usually will help, if the

gasket has lost its elasticity, it must be replaced. The reason for

loss of elasticity can be excessive heating or aging,

Cover gaskets, valves and gaskets of the tap changer. If there

are leaks, tightening will usually help,

Welded joints. Leaking joints can be repaired only by welding. A

skilled welder and a welding instruction are required.,

- 109.

©

ABB

Power

Technology

1_114Q07-

109

-

Maintenance

Cleaning contaminatedbushings (cleaning agent e.g.

methylated spirit),

Cleaning glasses on gas relay, thermometer and liquid level

indicator,

Functional inspection of applicable accessories,

Move tap changer through all positions a few times, all types of

tap changers,

Liquid sampling from bottom drain valve for larger units as

required,

Check drying material in the dehydrating breather. (Conservator

type only),

Amend surface treatment defects.

In heavily contaminated installations more frequent inspections may

be needed.

- 110.

©

ABB

Power

Technology

1_114Q07-

110

-

Maintenance. Transformer liquidand insulation

The task of liquid in a transformer is to act as an electrical insulation

and to transfer heat from the transformer’s active parts into coolers.

Liquid acts as a good electrical insulation only as long as it is

satisfactorily dry and clean.

Humidity balance between the oil and the insulation implies that

most of the humidity will gather in the paper insulation.

Testing of liquid in transformers should normally be performed 12

months after filling or refilling, subsequently every six years.

Testing of oil in on load tap changers must be performed according

to the tap changer supplier’s recommendations.

To take liquid samples from hermetically sealed transformers is

normally not necessary. The liquid in this type of transformers is not

in contact with the atmosphere, and less exposed to moisture.

Especially for large transformers, liquid regeneration may be

economically motivated. Liquid regeneration implies drying, filtering,

de-gassing and possibly addition of inhibitor.

- 111.

©

ABB

Power

Technology

1_114Q07-

111

-

Maintenance. Bushings andjoints

The porcelain insulators of transformer bushings ought to be

cleaned during service interruptions as often as necessary. This is

particularly important for places exposed to contamination and

moisture.

Methylated spirit or easily evaporating cleaning agents can be used

for cleaning.

The condition of external conductor and bus bar joints of

transformer bushings shall be checked at regular intervals because

reduced contact pressure in the joints leads to overheated bushings

etc. and may cause the adjacent gasket to be destroyed by the

heat.