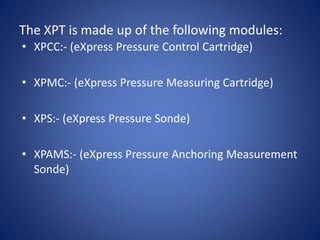

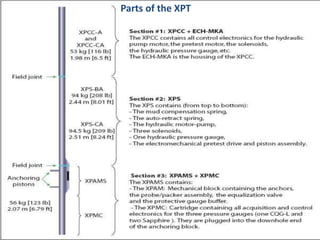

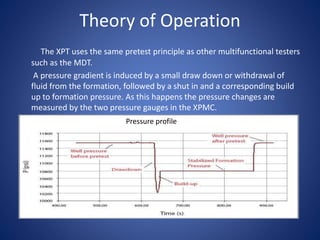

The document summarizes wireline operations using the eXpress Pressure Tool (XPT). It describes maintenance procedures like F.I.T., T.R.I.M., and Q-Check to inspect and calibrate tools. It then explains that the XPT is used to measure formation pressure at different depths and generate a pressure profile. The XPT has modules like the XPCC, XPMC, XPS, and XPAMS that control operations and enable anchoring, probing, and pressure measurement. It concludes the XPT allows unlimited tests in a single run and greatly reduces time for formation testing compared to other tools.