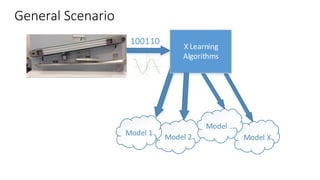

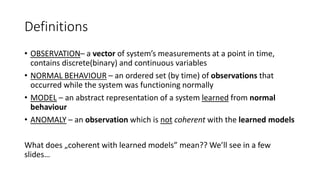

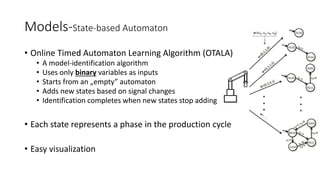

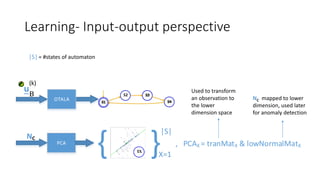

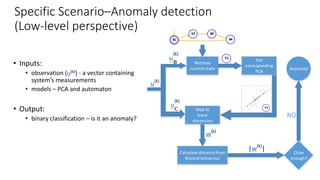

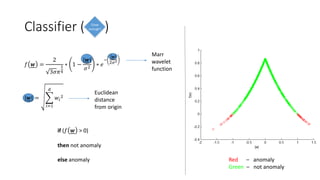

1) The document proposes using machine learning techniques like OTALA and PCA to automatically build models of production systems and detect anomalies in real-time without needing expert knowledge of the system's components.

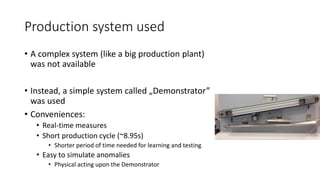

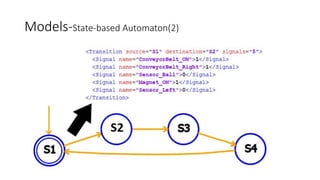

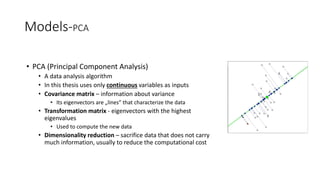

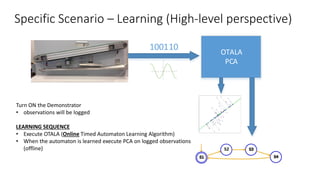

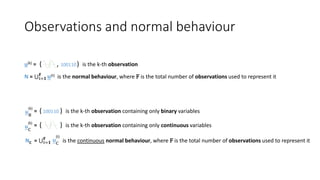

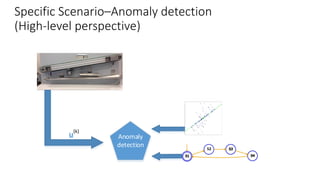

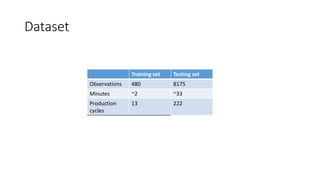

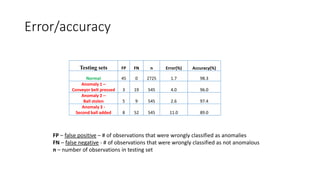

2) It tests this approach on a "Demonstrator" production system, using OTALA to model normal behavior as a state machine and PCA to reduce data dimensions. It then detects anomalies by comparing new data to these models.

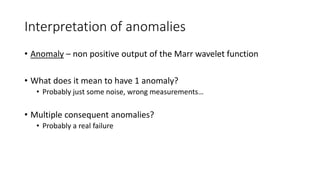

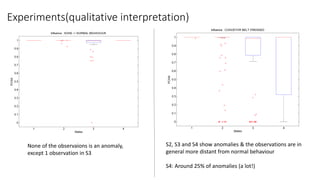

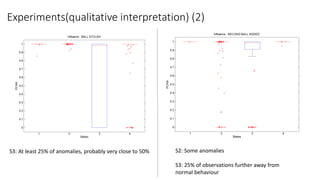

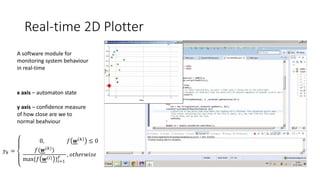

3) Experiments show this approach can accurately detect various introduced anomalies, though it cannot diagnose their specific causes. The models also allow monitoring system behavior in real-time.