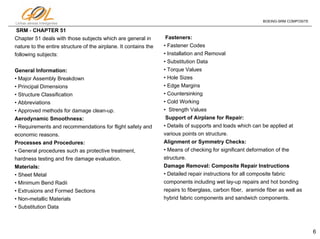

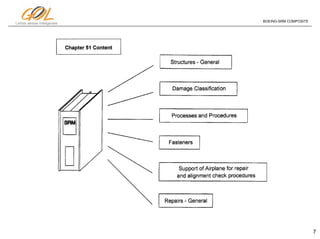

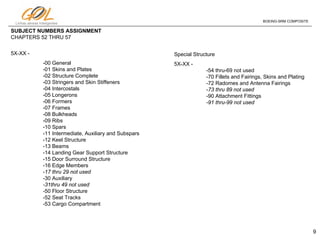

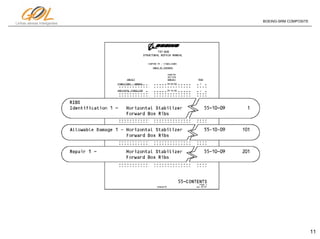

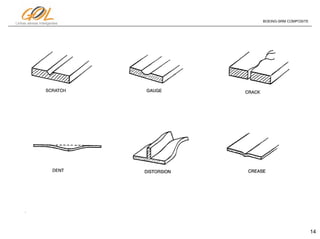

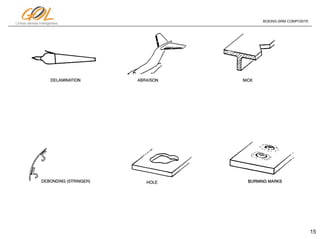

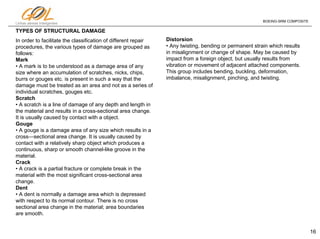

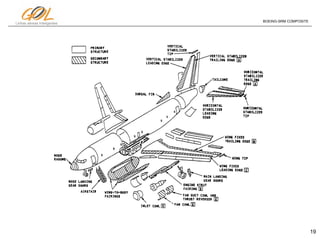

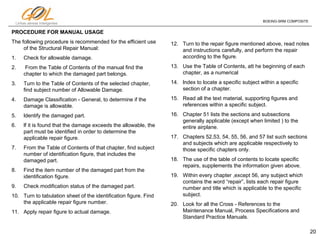

The document discusses the purpose and contents of a Structural Repair Manual (SRM) published by aircraft manufacturers. The SRM provides guidance for repairing structural damage to commercial airplanes. It contains information on material identification, typical repairs, material substitution, and repair procedures. The SRM is divided into chapters that correspond to major airplane components like the fuselage, wings, and stabilizers. It also provides classifications for types of damage and guidelines for investigating damage.