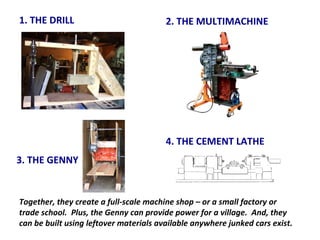

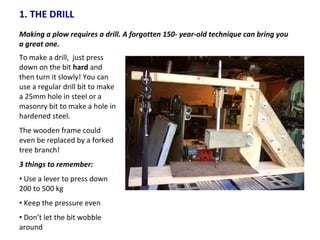

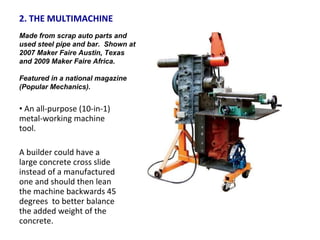

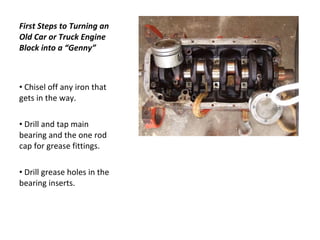

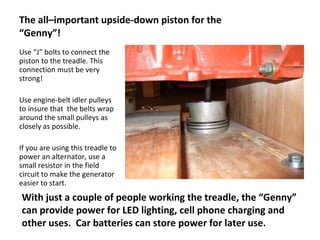

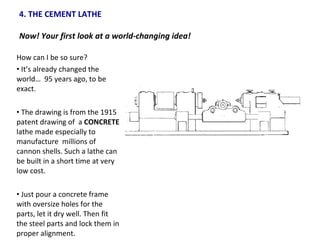

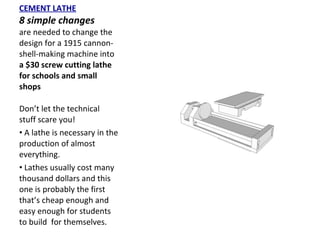

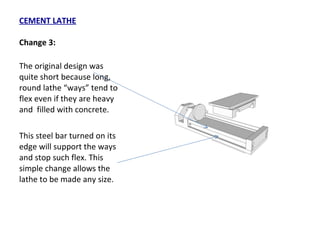

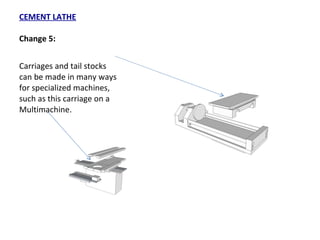

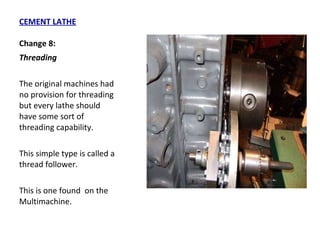

The document outlines four open-source tools designed for African rural development, which can be built from scrap materials: a drill, a multimachine, a genny for generating power, and a cement lathe. Each tool has unique applications, such as farming, training, and powering village needs, enabling communities to create machine shops or small factories. Detailed instructions and modifications are provided for building these tools affordably and effectively.

![For much more information about building any of these machines go to http://groups.yahoo.com/group/multimachine/ For the Genny, also go to http://groups.yahoo.com/group/africapowerandlight/ For the original L.I. Yeomans concrete lathe patent, Google for patent number 1,154,155 For personal help on any of these projects: email Pat Delany [email_address]](https://image.slidesharecdn.com/4simplecheaptoolsforafricamn1-100825005058-phpapp01/85/4-simple-cheap-tools-for-Africa-19-320.jpg)