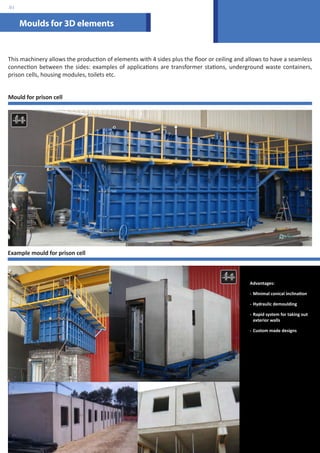

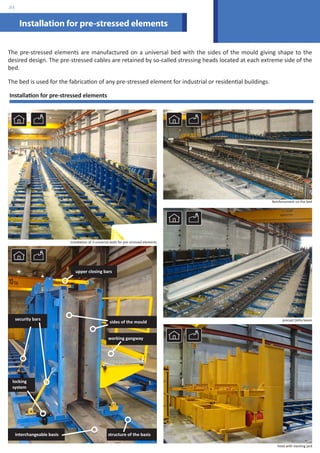

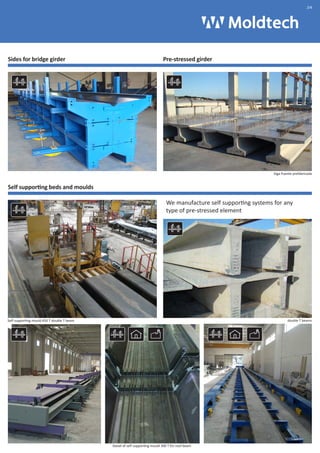

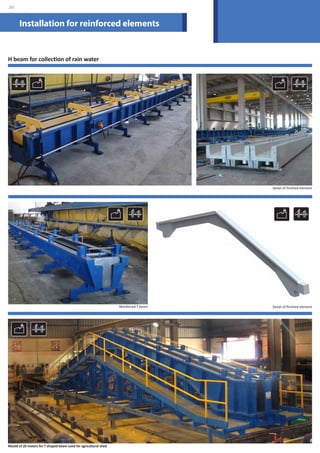

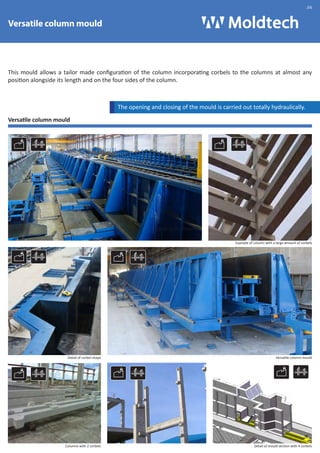

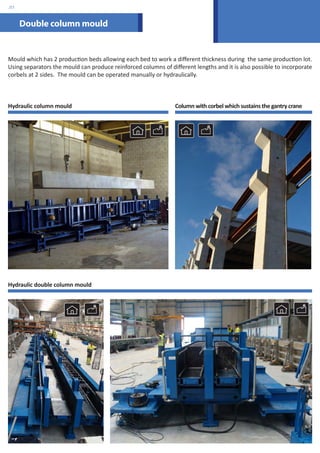

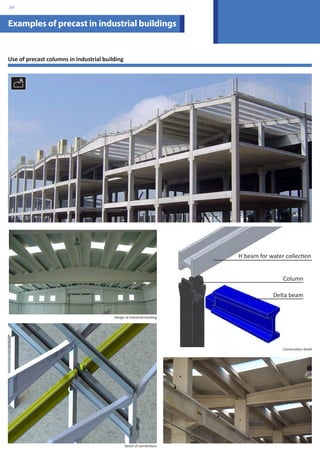

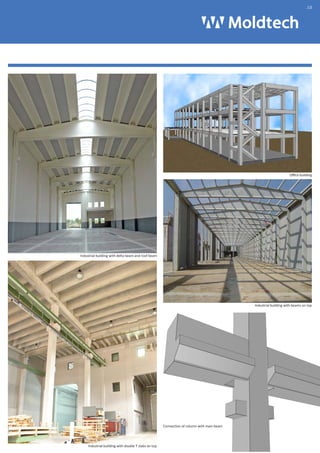

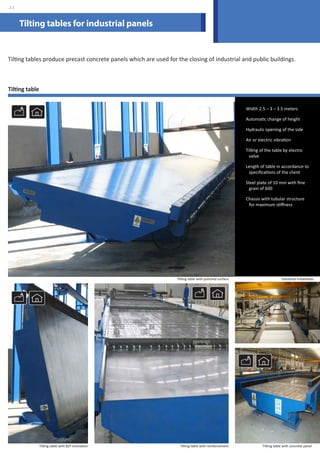

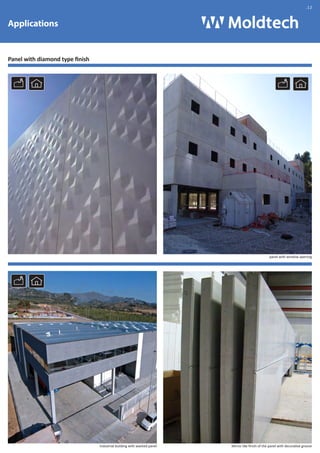

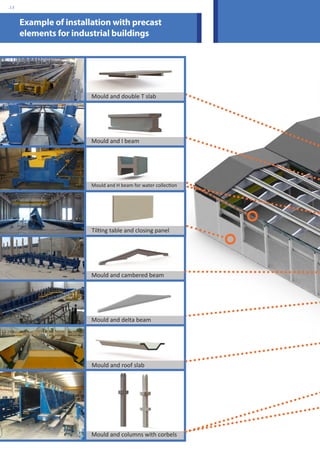

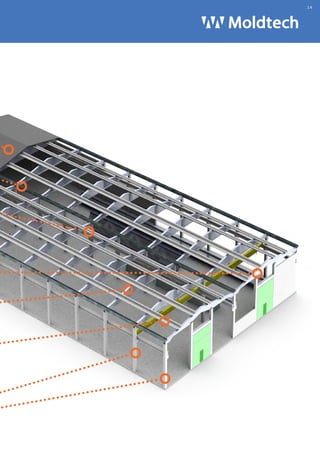

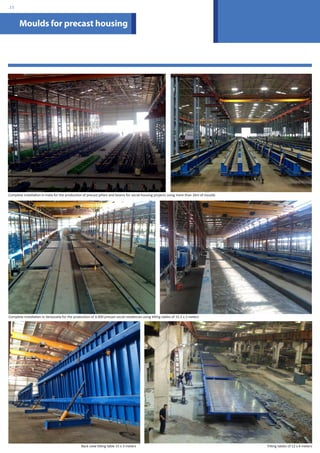

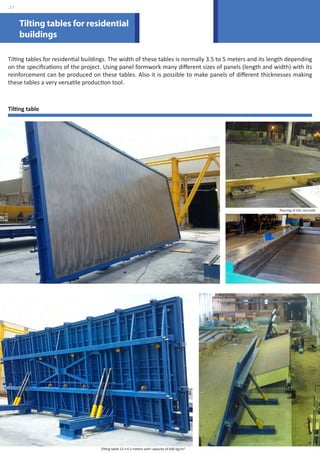

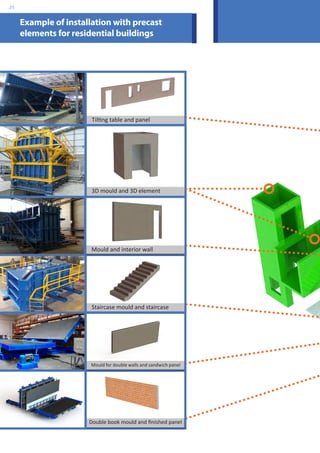

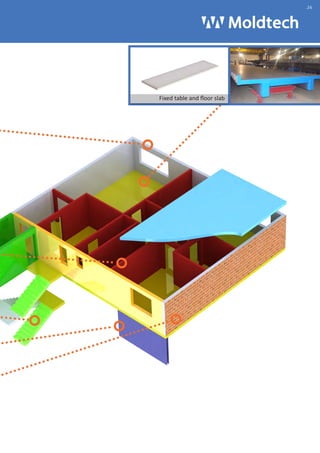

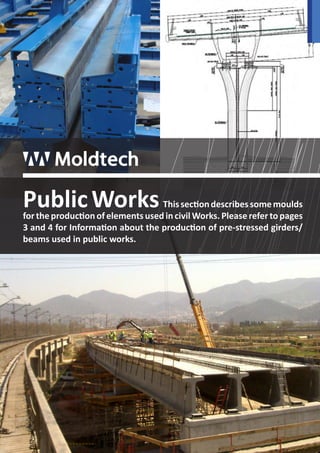

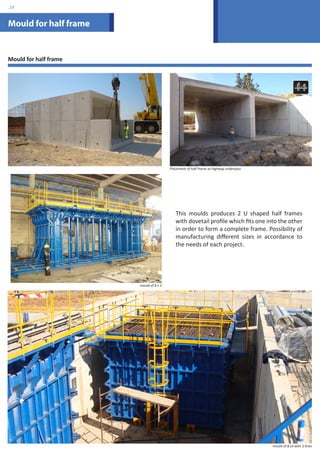

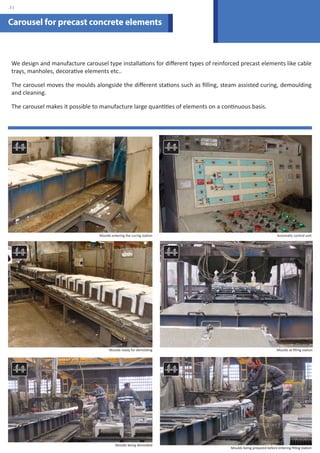

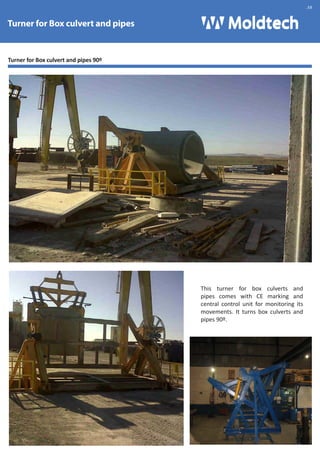

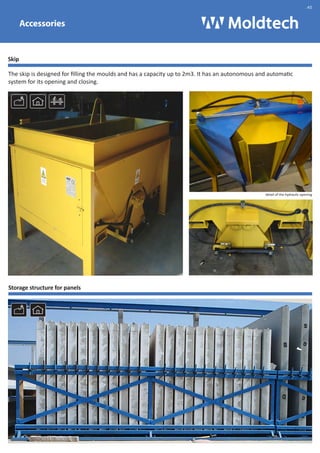

This document provides information about Moldtech SL, a Spanish company that designs and manufactures molds for precast concrete elements. It details the types of molds they produce for industrial, residential, and public works applications. Their products include molds for 3D elements, pre-stressed elements, reinforced elements, columns, walls, floors, and more. The company aims to provide innovative solutions and a full service approach from design to installation and support.