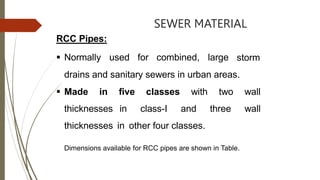

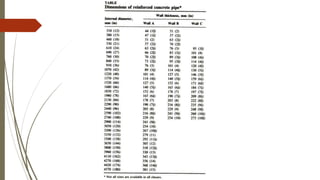

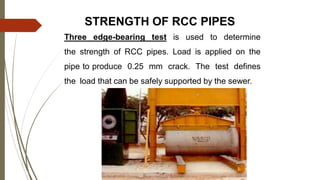

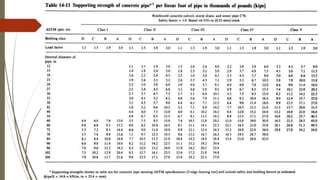

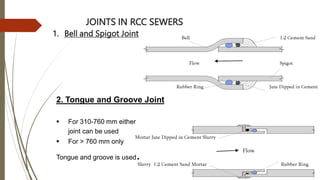

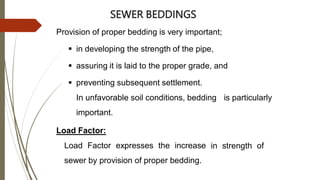

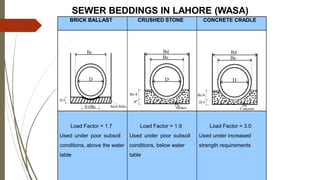

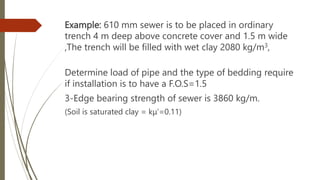

The document discusses materials and design considerations for sewer pipes. Reinforced concrete cement (RCC) pipes are commonly used for large storm and sanitary sewers in urban areas. RCC pipe strength is determined through three edge-bearing tests. Joints for RCC sewers smaller than 760mm can be bell-and-spigot or tongue-and-groove, while only tongue-and-groove joints are used for larger pipes. Proper bedding is important for developing pipe strength, maintaining grade, and preventing settlement. Common bedding methods provide load factors of 1.7 to 3 to increase a pipe's load-bearing capacity.