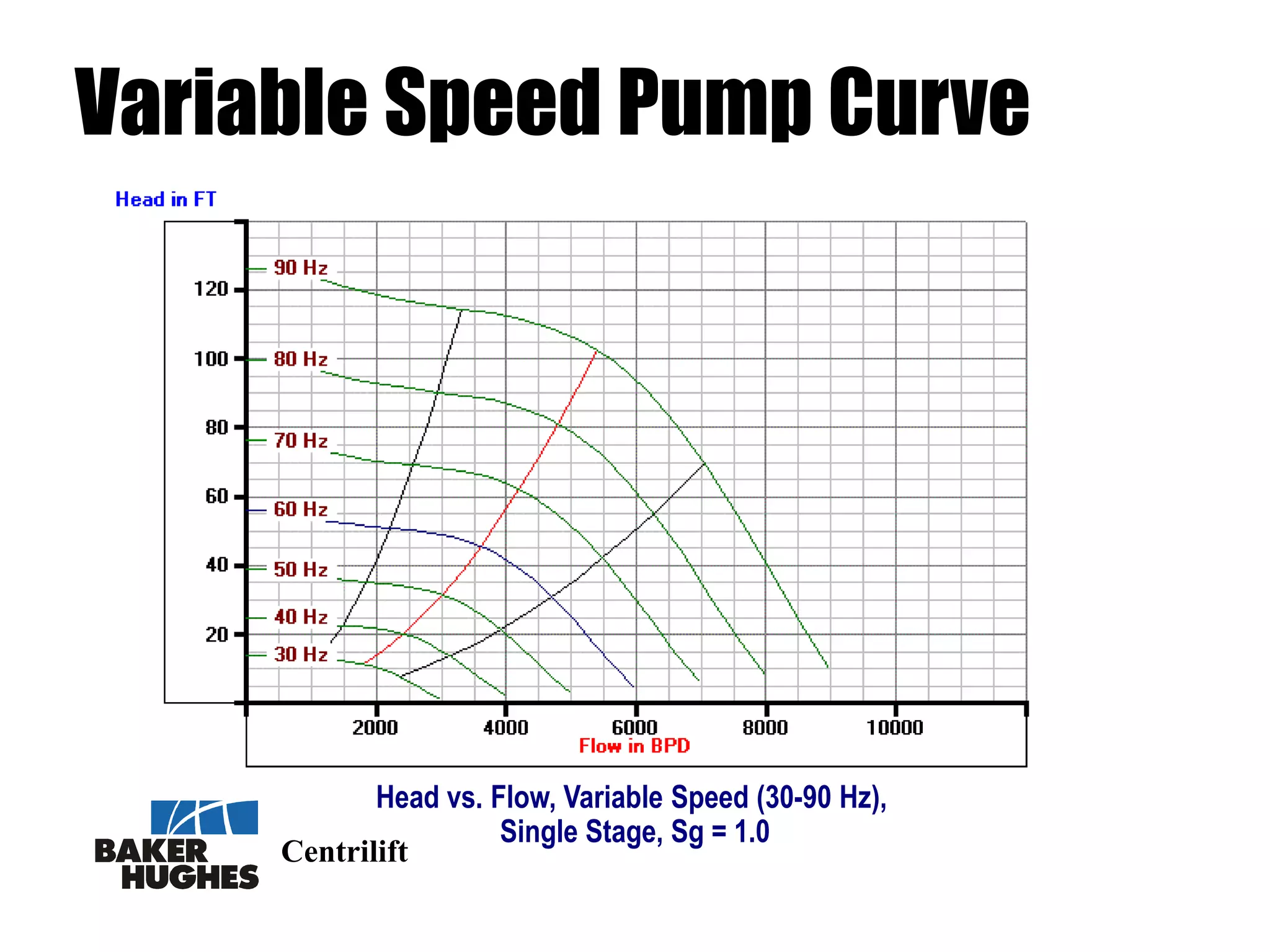

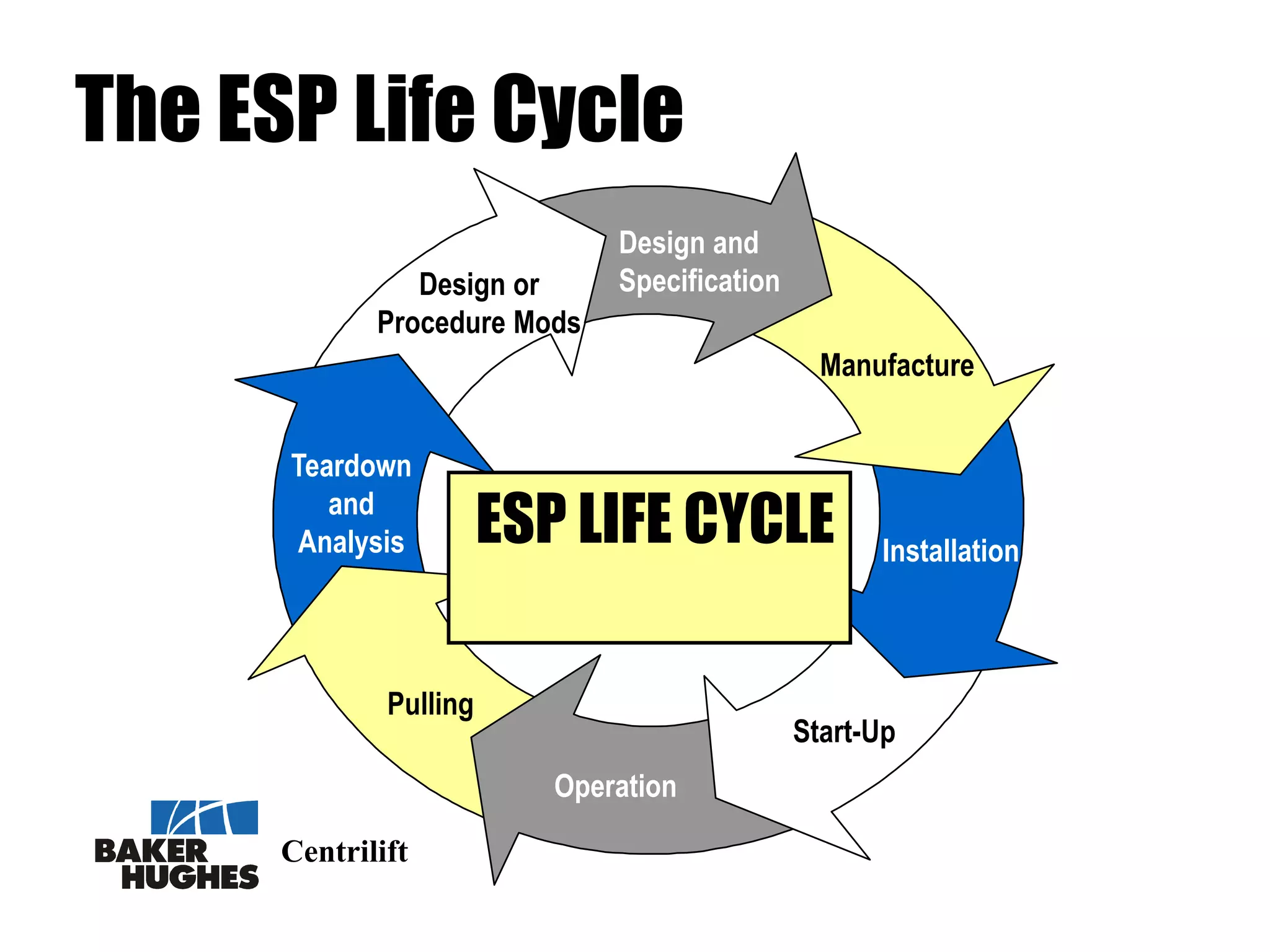

This document discusses factors that affect the run life of electric submersible pumps (ESPs) used in oil wells. It identifies the main factors as proper sizing of equipment, well temperature, presence of free gas, fluid viscosity, corrosion, sand production, deposition, electrical failures, operational problems, and age. It provides examples of how each factor can limit run life and recommends solutions to mitigate each factor's impact. The document emphasizes the importance of monitoring production rate, pump intake pressure, and motor current to optimize ESP operation and troubleshoot problems.