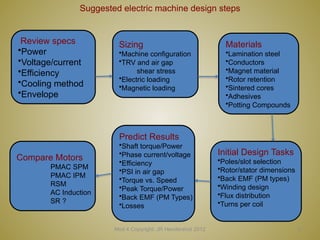

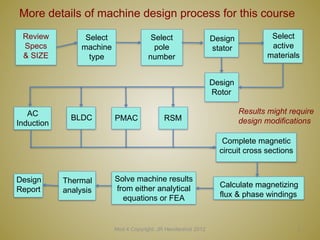

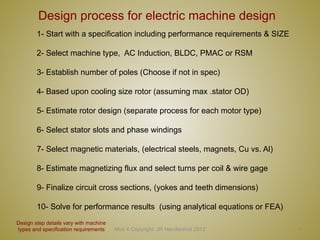

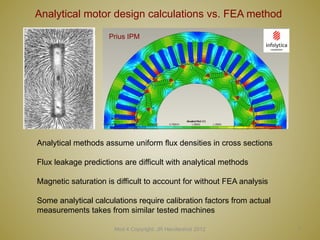

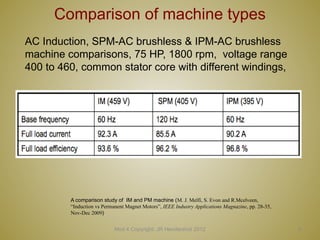

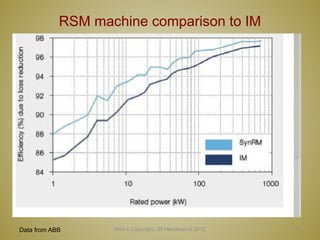

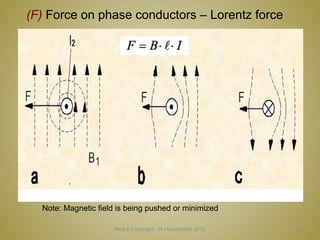

The document outlines the practical design process for electrical machines, detailing steps such as reviewing specifications, selecting machine types, designing rotor and stator, and predicting performance results. It contrasts classical design methodologies with practical guidelines for engineers and emphasizes the importance of torque production and efficiency in both motoring and generating applications. Additionally, the text includes considerations for materials, cooling methods, and the design of common components for various types of electrical machines.