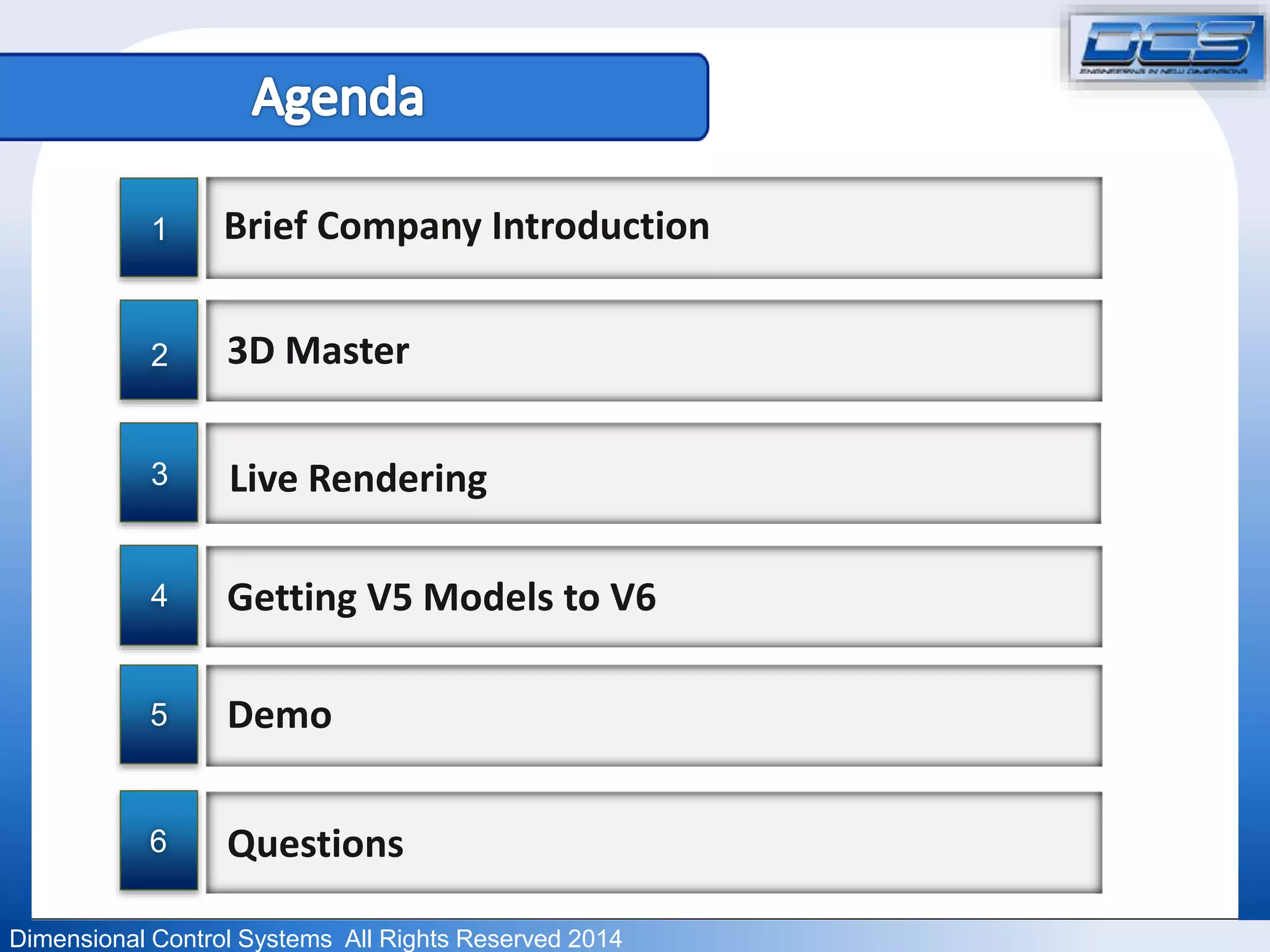

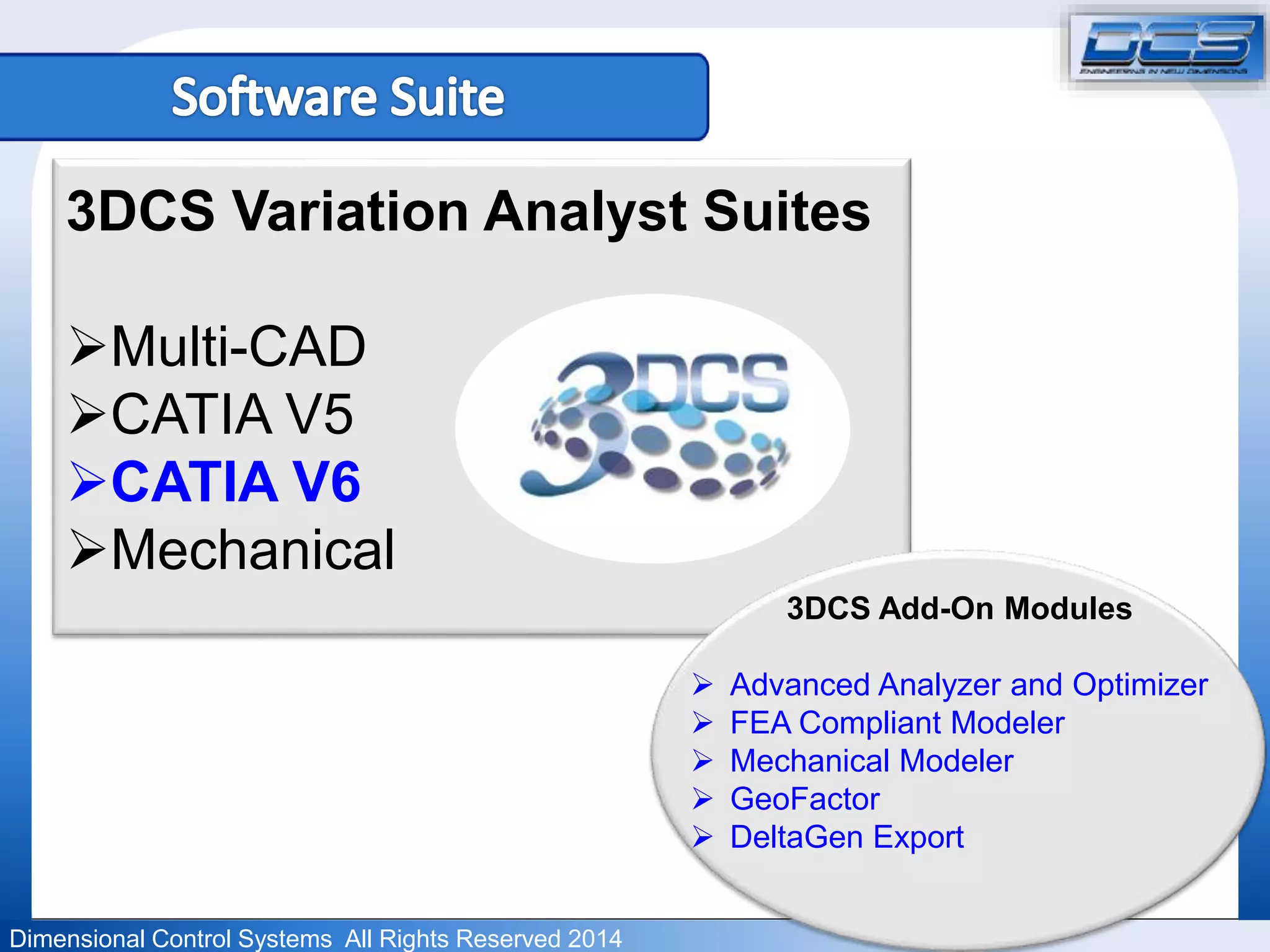

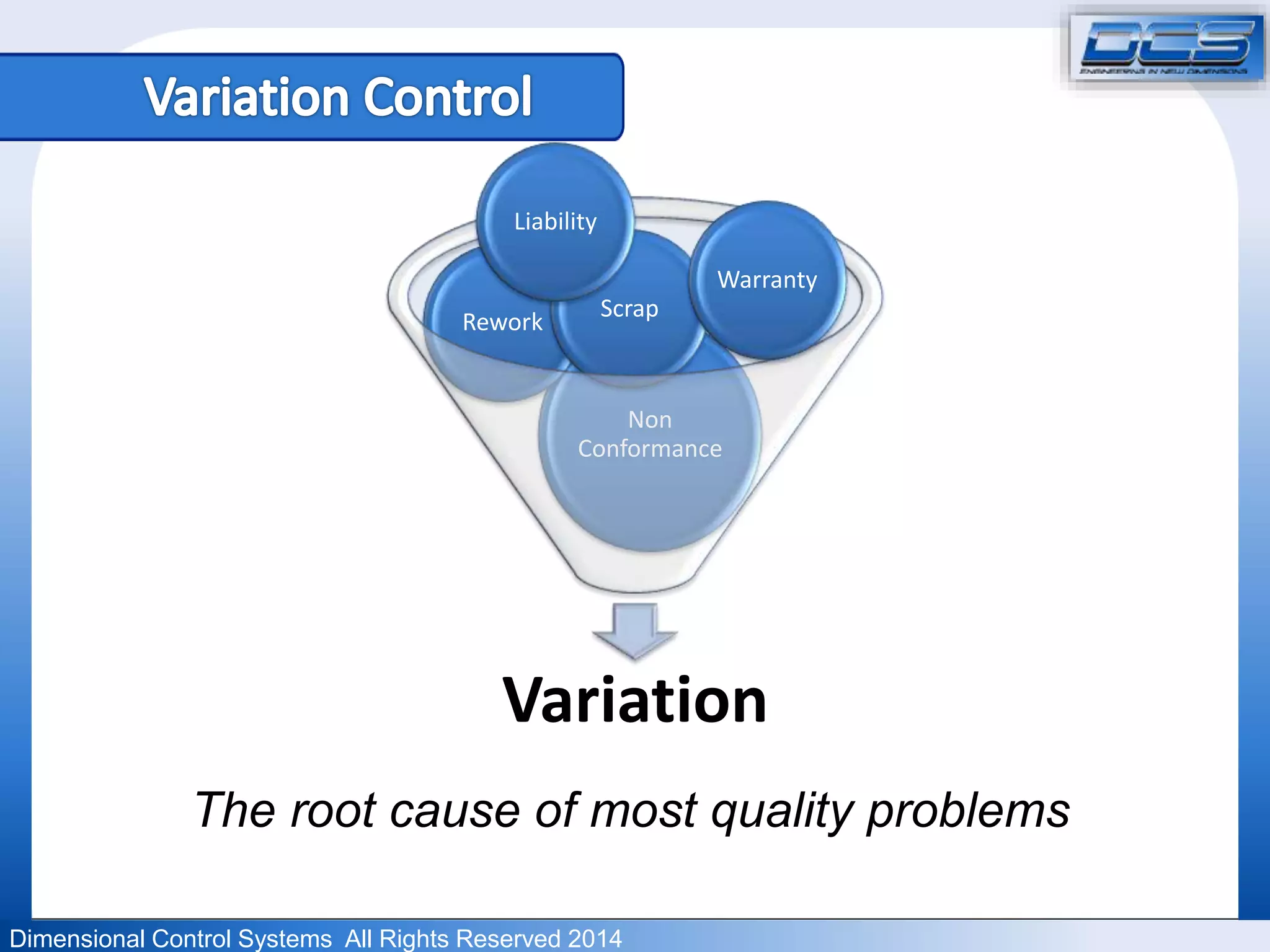

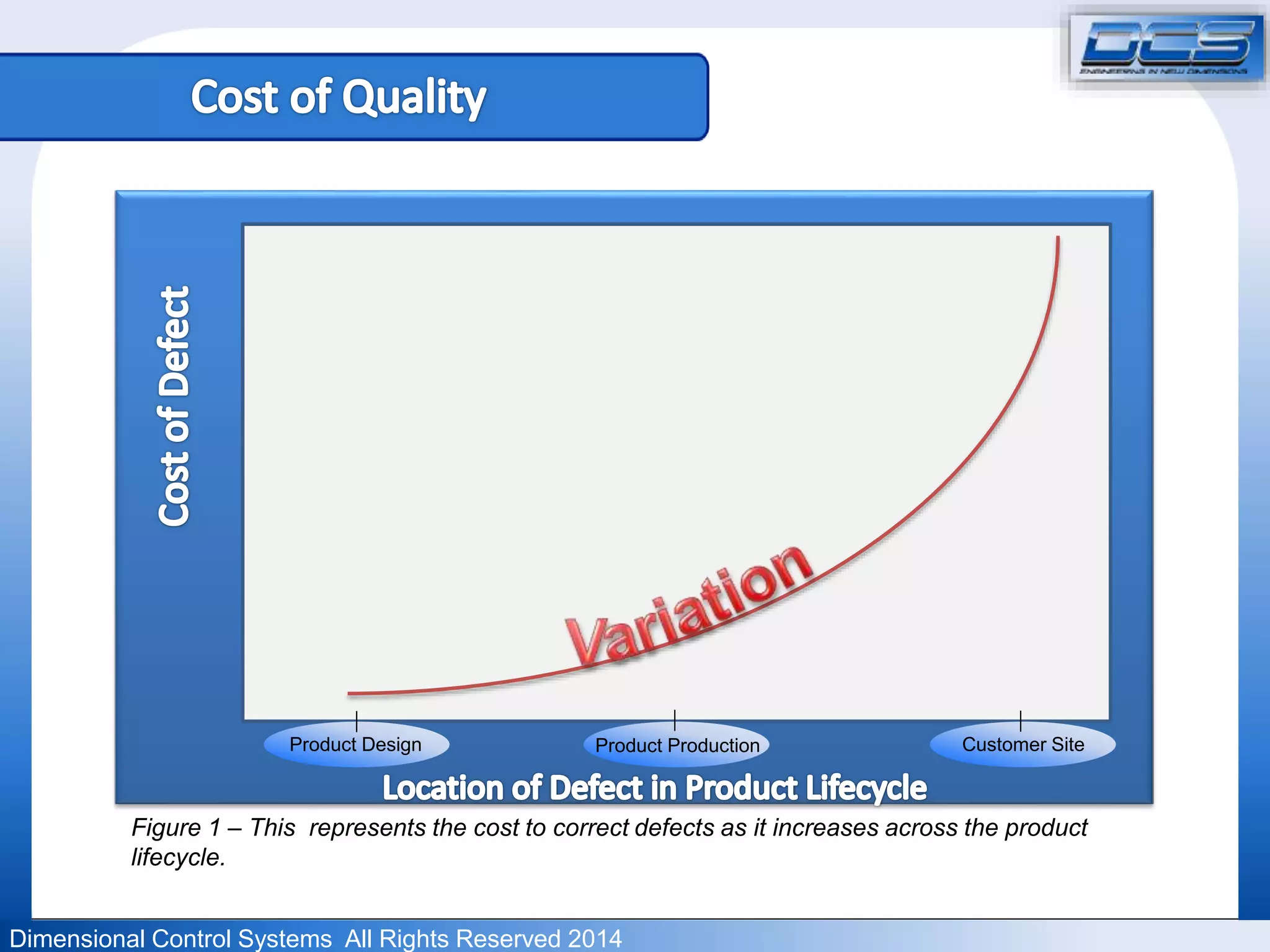

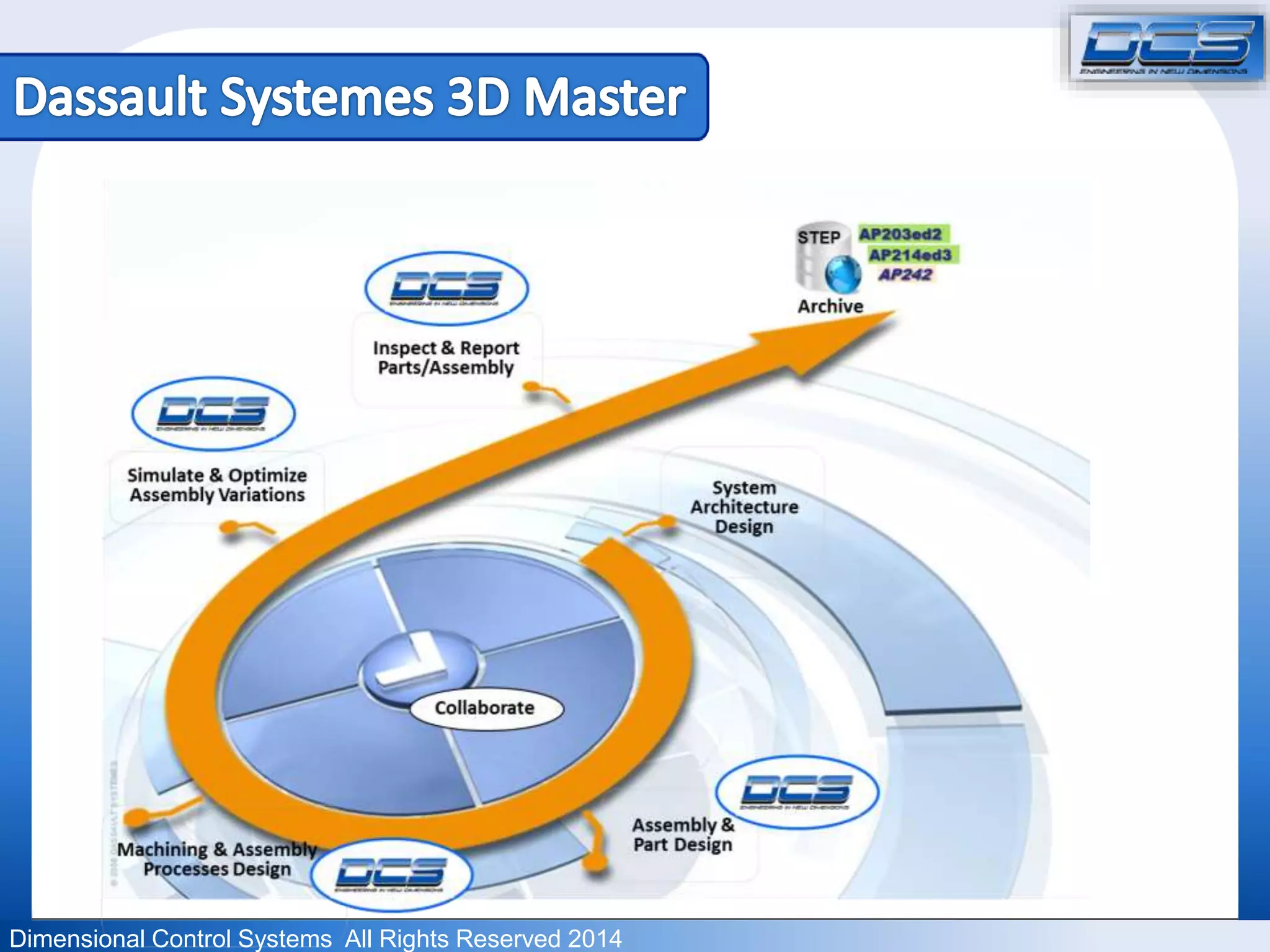

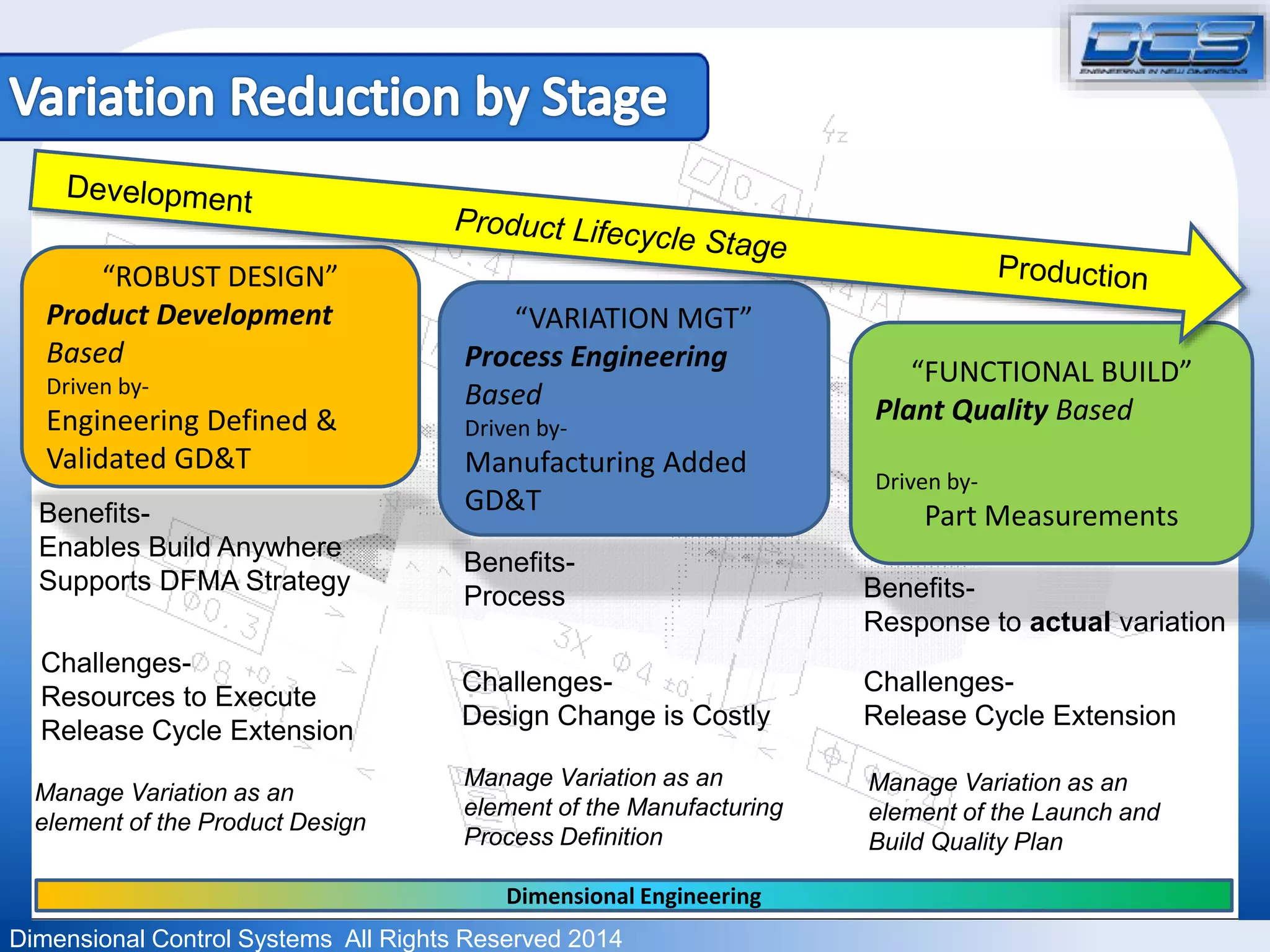

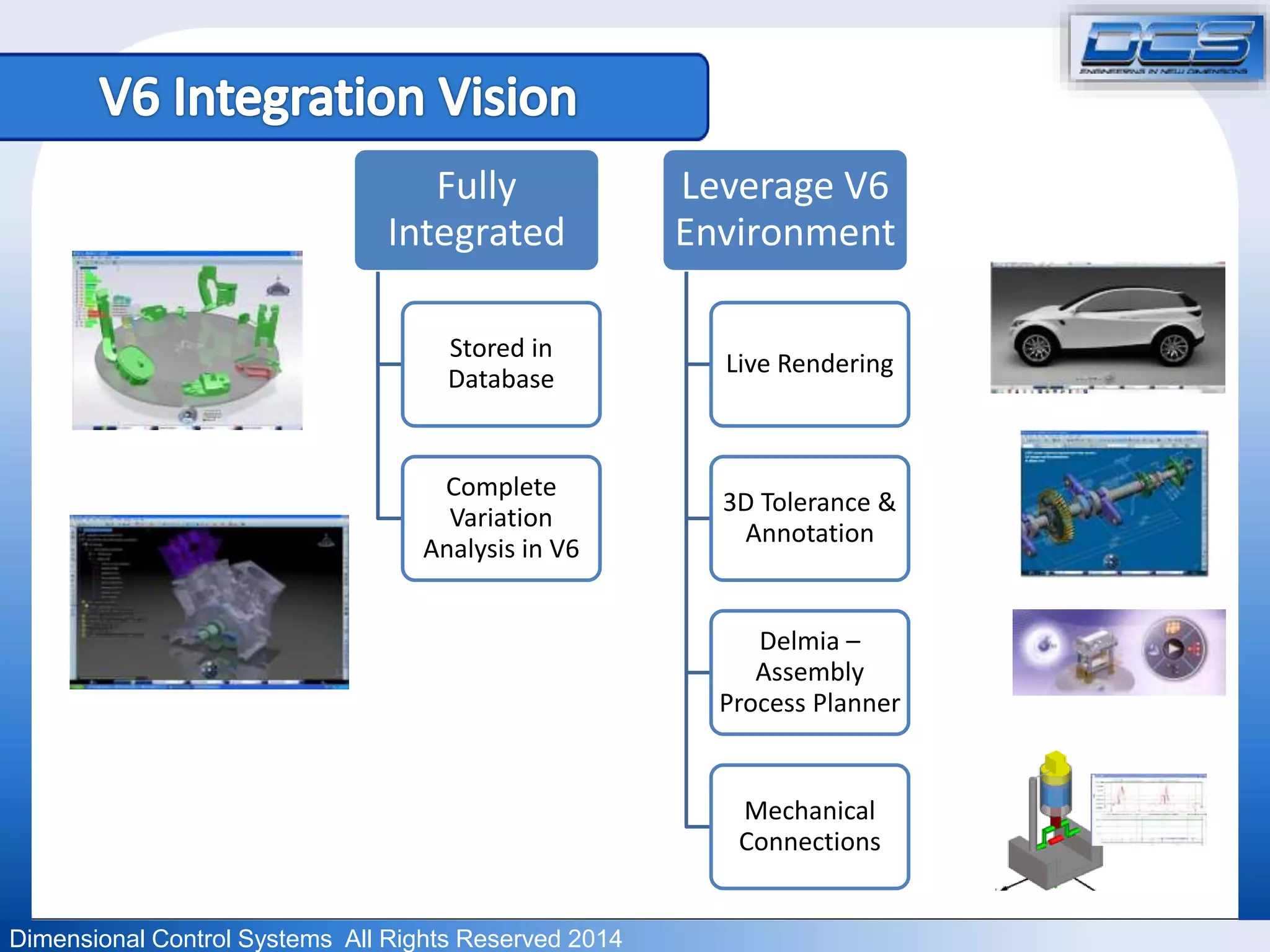

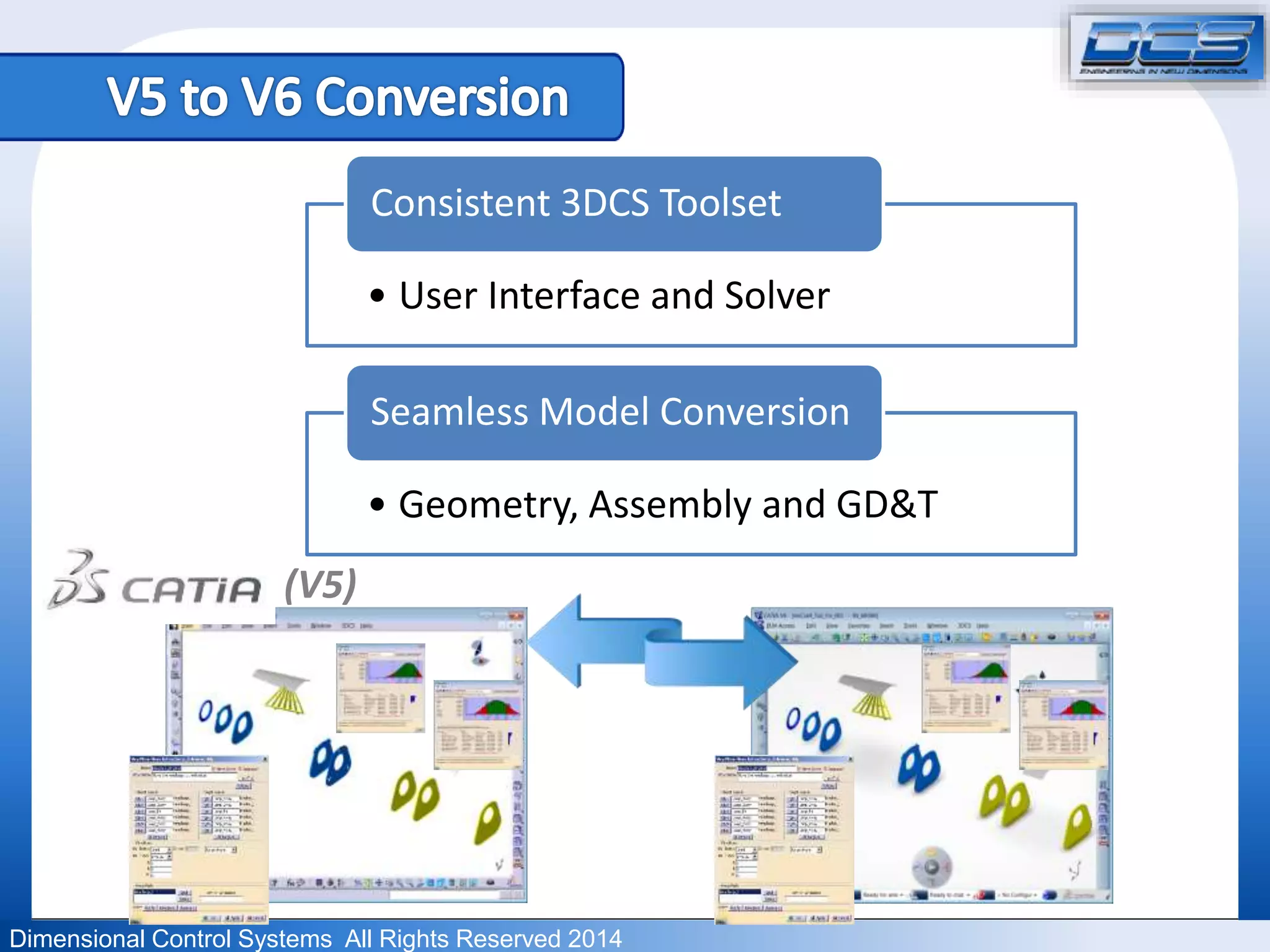

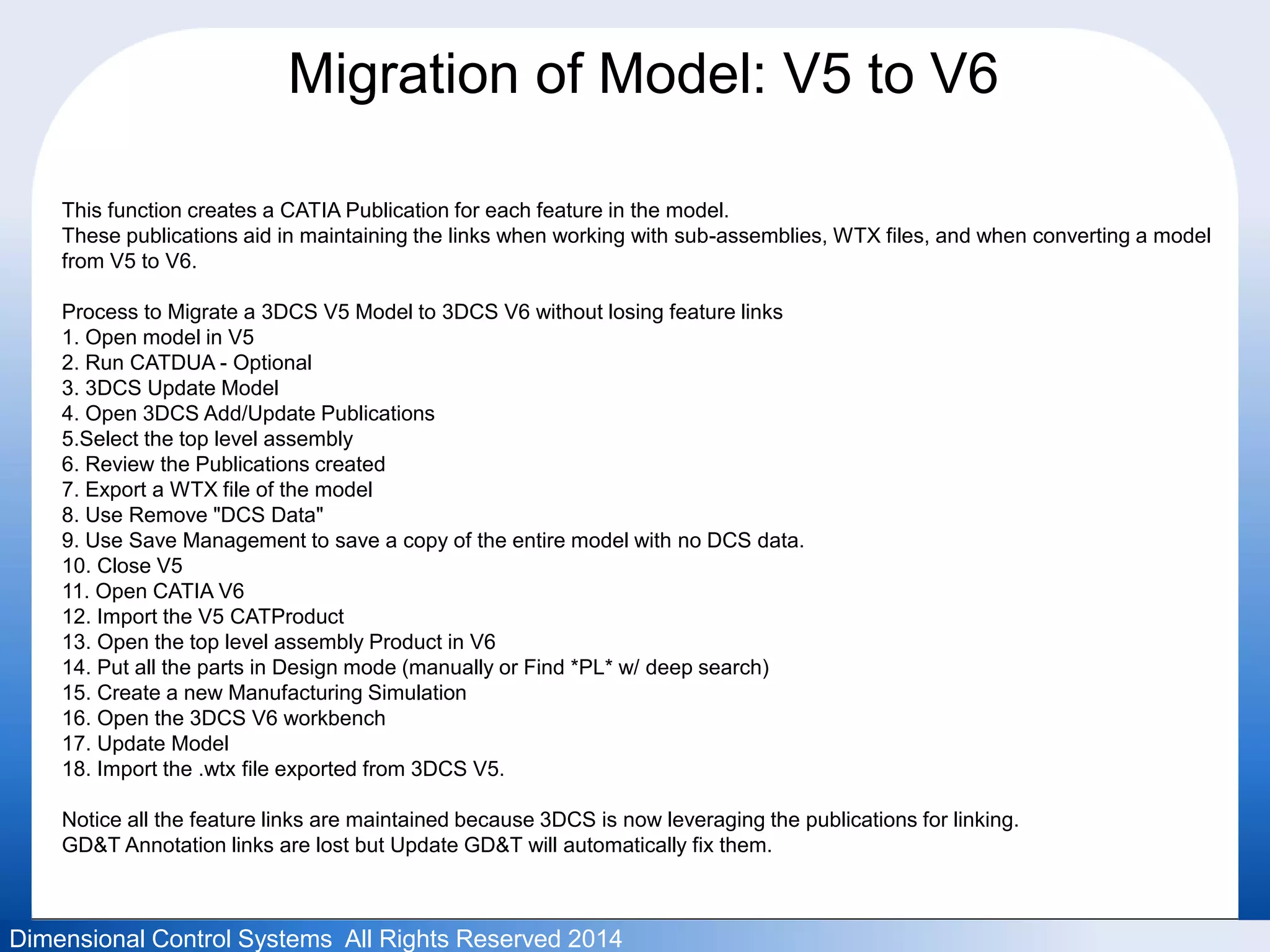

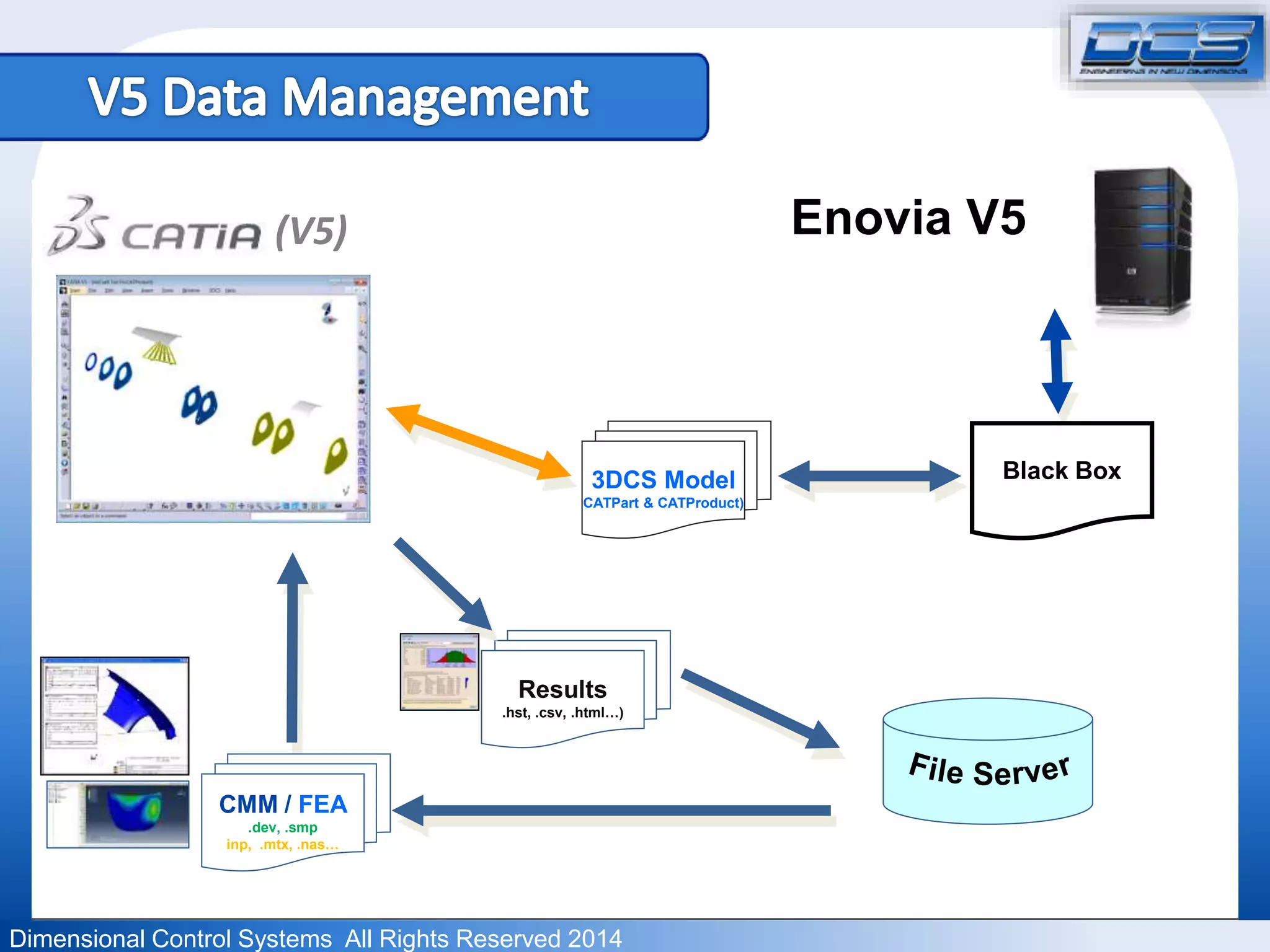

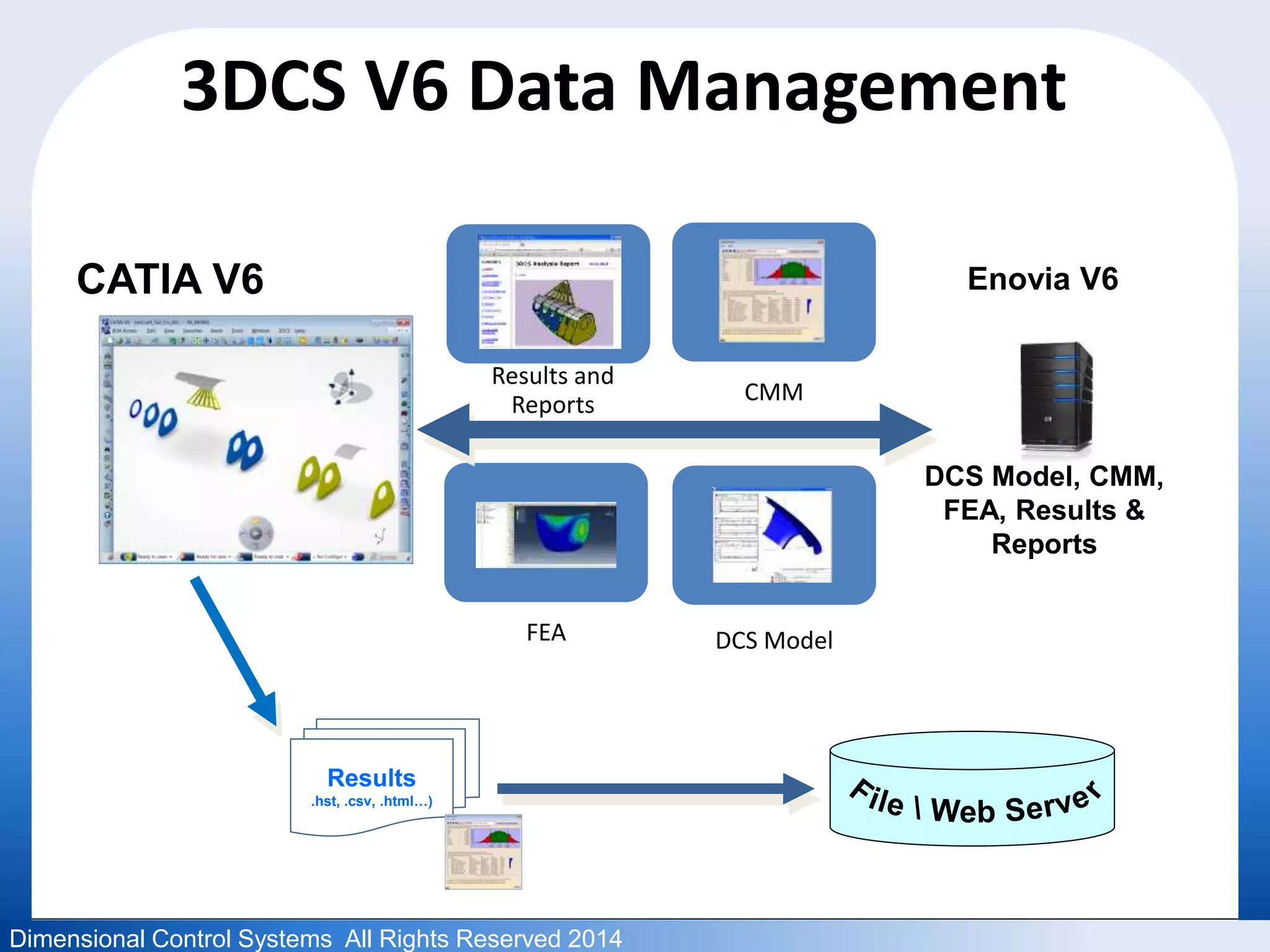

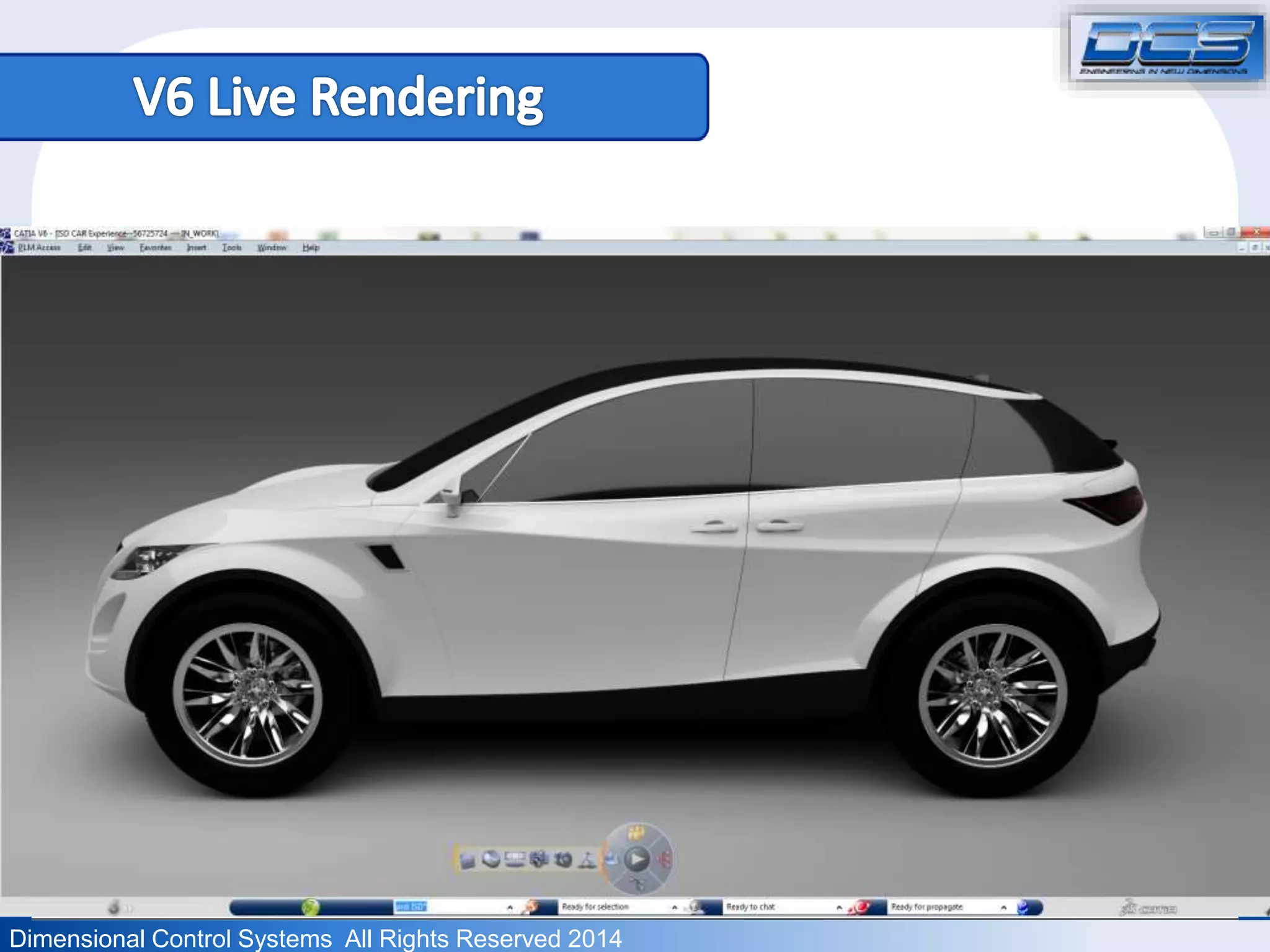

The document presents a comprehensive overview of dimensional control systems, including the introduction of 3DCS variation analysis software and its evolution from CATIA V5 to V6. It emphasizes the importance of managing variation and quality throughout the product lifecycle, outlining the benefits of robust design and functional build processes. Additionally, it details the model migration process from V5 to V6, highlighting feature link maintenance and GD&T annotation updates.