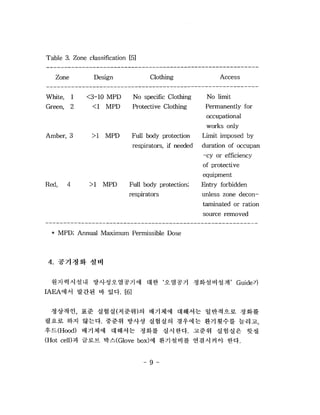

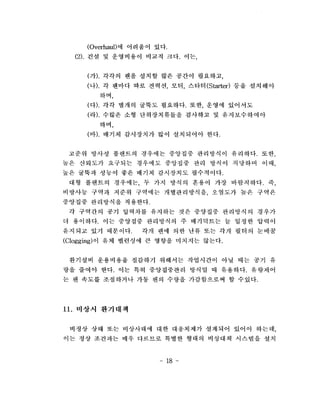

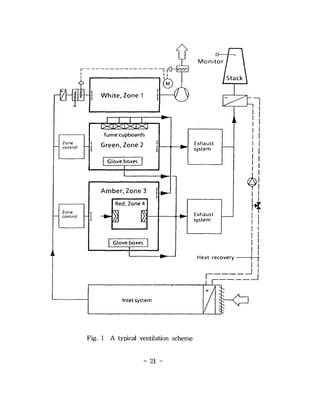

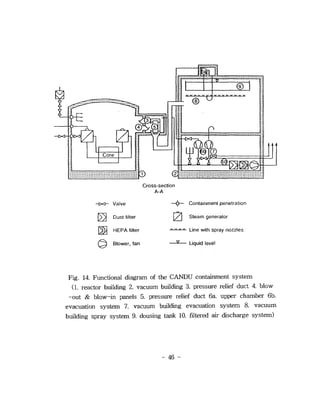

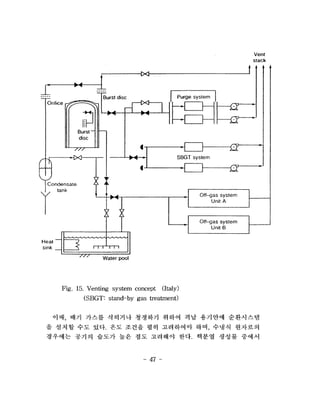

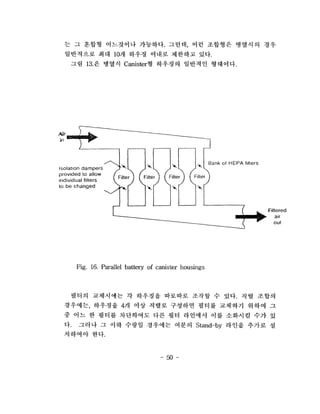

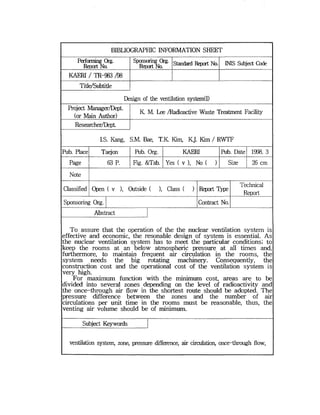

The document discusses the design of ventilation systems for nuclear facilities. The primary purposes of a nuclear ventilation system are to remove and reduce the release of radioactivity to the environment and maintain a safe facility atmosphere. For maximum effectiveness with minimum cost, areas should be divided into zones based on radioactivity levels and once-through air flow should take the shortest route between zones. The pressure differences between zones and air circulation rates must be reasonable to minimize the volume of vented air requiring cleaning or filtration.