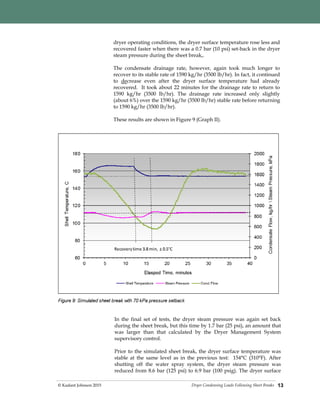

This document discusses the effects of sheet breaks on dryer condensing loads in papermaking machines, highlighting misconceptions about increased condensing rates during recovery. It details an experimental study that measured condensate evacuation rates and analyzed the impact of steam pressure adjustments during and after a sheet break. The findings clarify that while there may be temporary fluctuations in condensing rates, they do not significantly exceed pre-break levels unless the steam control system is inadequate.