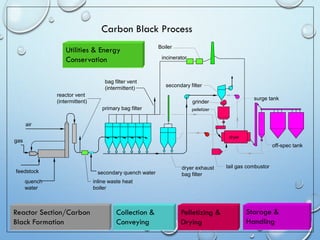

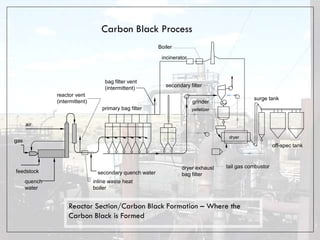

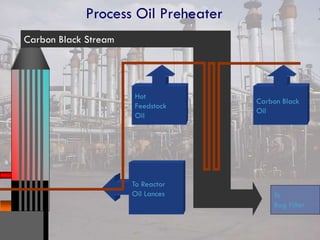

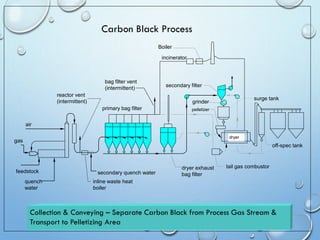

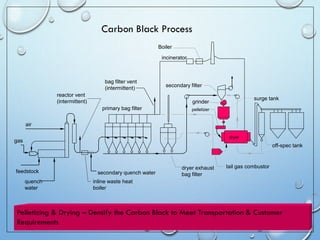

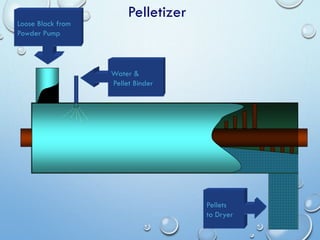

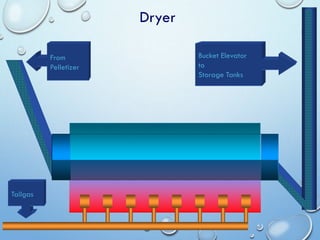

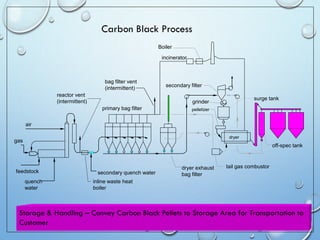

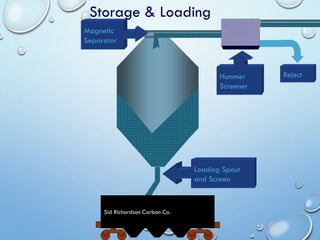

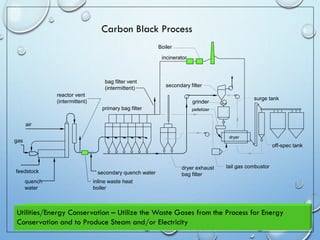

This document outlines the process for producing carbon black from waste tires. It describes the objectives of gaining skills and knowledge of the process. The key steps involve preheating air and oil, spraying the preheated materials into a high-temperature reactor to produce carbon black, quenching and filtering the product, pelletizing, drying, and storing the carbon black. Issues addressed include salt waste and maintenance of refractory reactor components. Lessons learned include safety practices at high temperatures, communication, and incorporating feedback. Future work proposed involves mass and energy balancing and heat exchanger design.