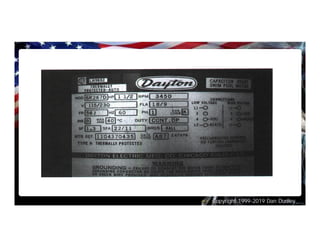

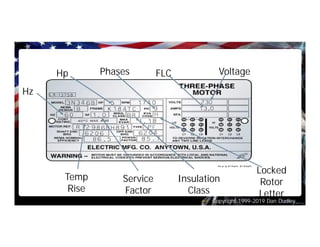

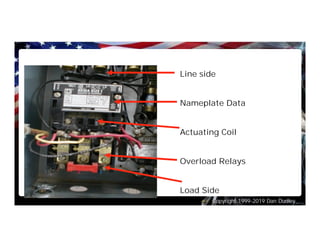

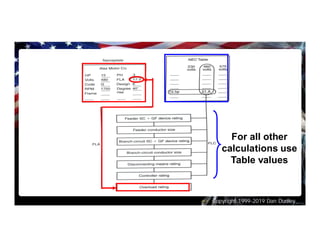

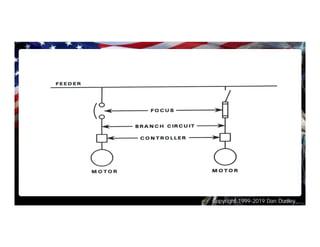

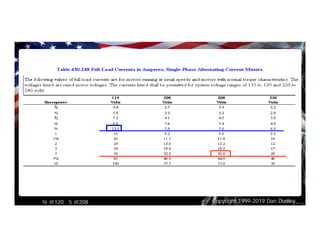

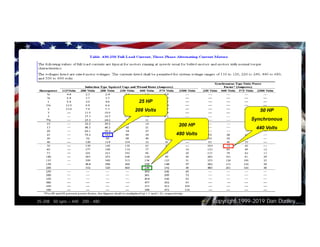

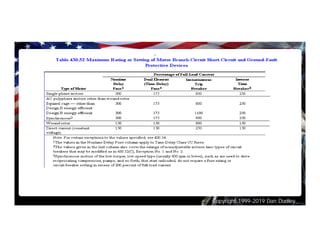

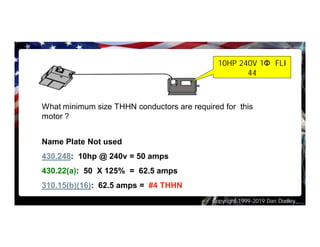

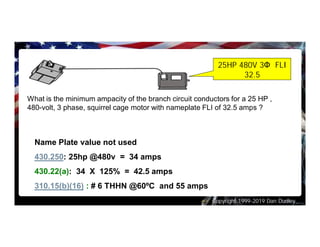

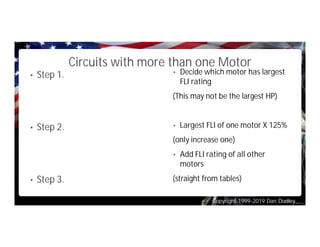

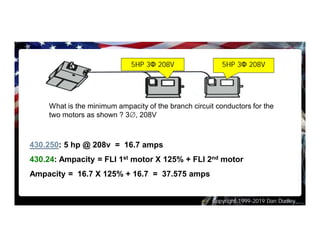

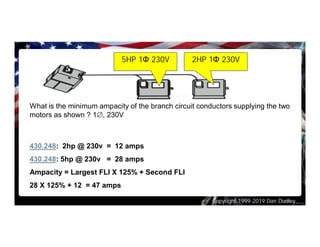

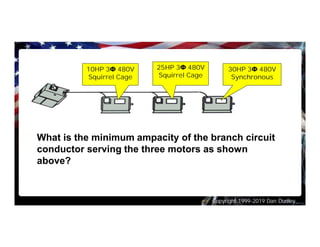

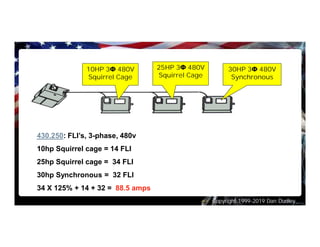

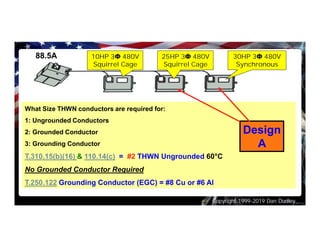

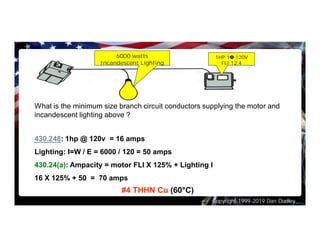

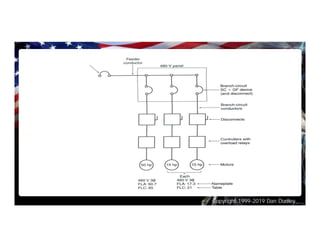

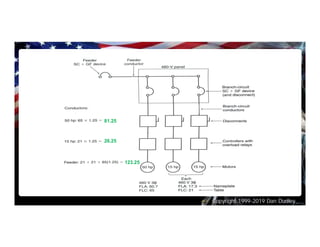

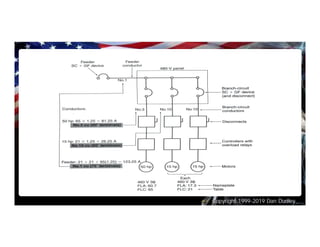

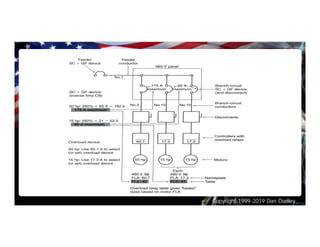

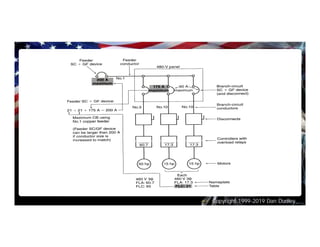

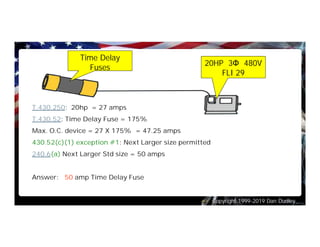

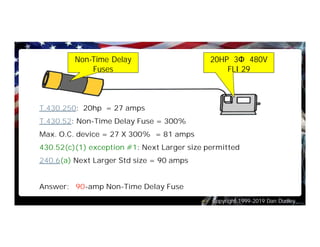

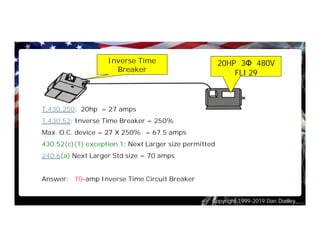

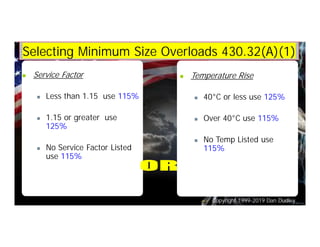

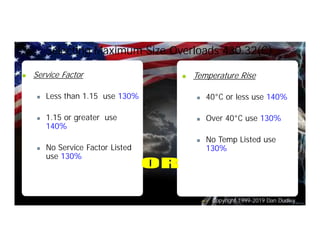

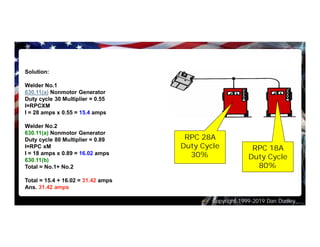

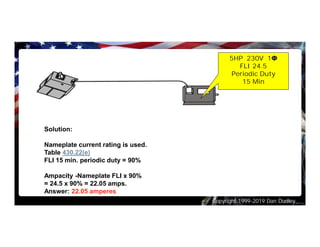

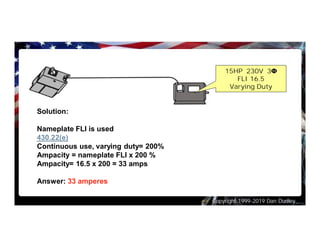

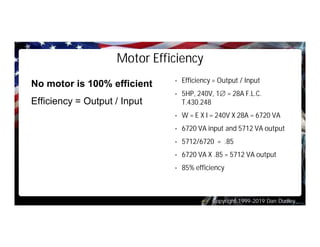

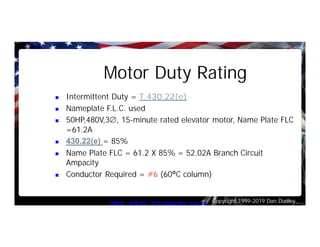

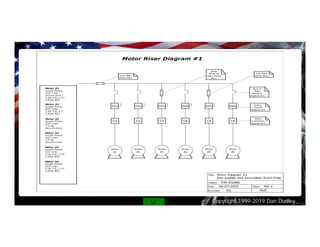

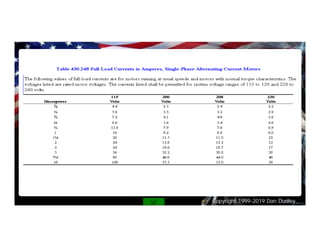

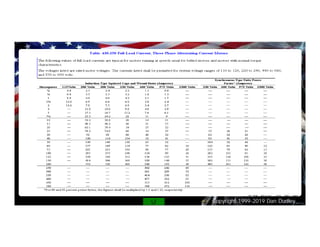

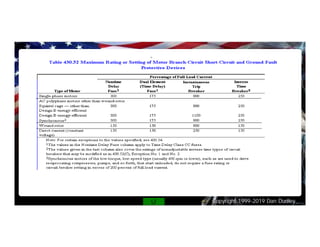

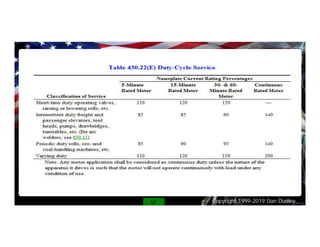

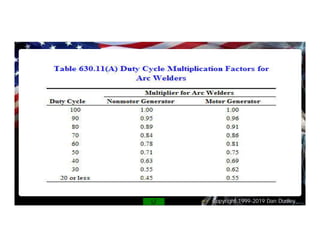

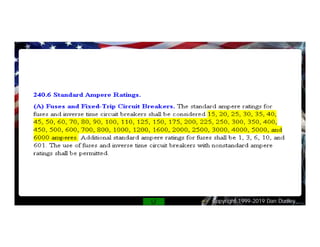

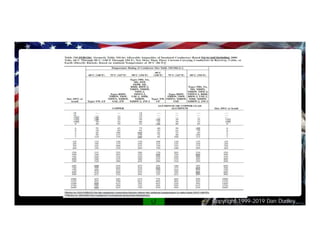

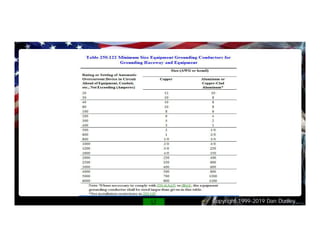

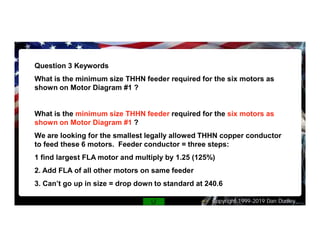

The document provides detailed guidelines and calculations based on the NEC requirements for motor circuit calculations, including overload sizing, short circuit protection, and conductor sizing for different motors. It emphasizes specific formulas and tables to determine appropriate sizes for electrical components depending on the motor specifications and operating conditions. Additionally, it includes example calculations for various motor types, ensuring compliance with safety and efficiency standards.