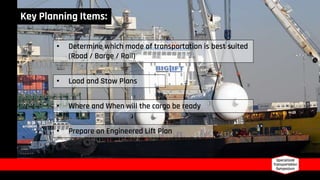

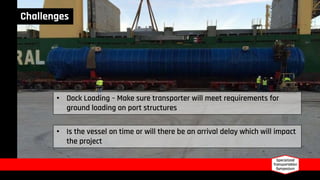

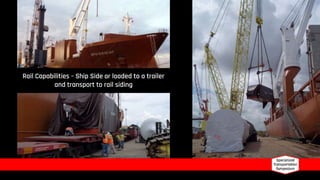

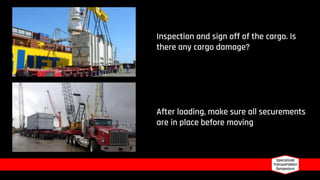

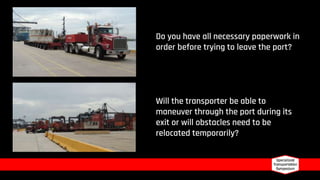

Partnering with ports requires extensive planning and coordination between multiple stakeholders. Communication is key to the safe and successful completion of projects involving cargo transport through ports. Planning must account for loading and transport logistics, infrastructure strength verification, and contingencies to address potential delays or issues that could arise. Thorough planning is necessary to navigate the complex port environment and regulations successfully.