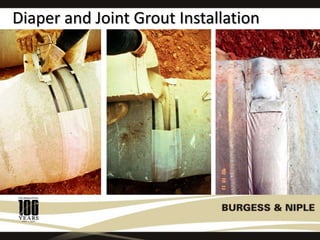

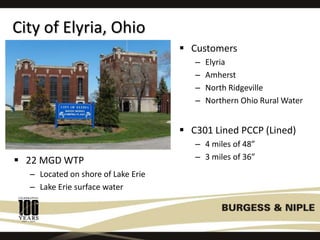

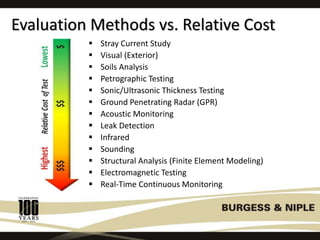

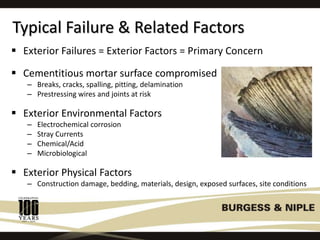

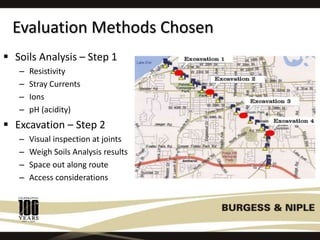

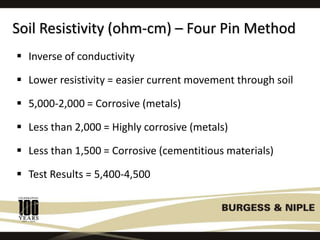

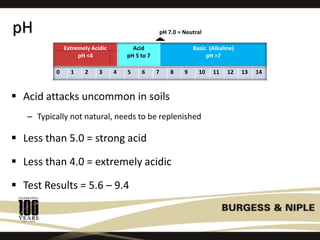

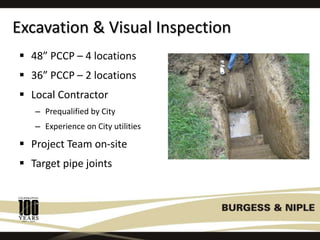

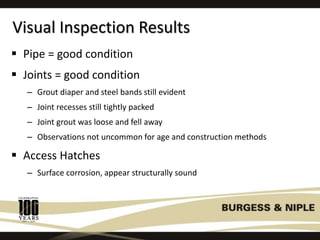

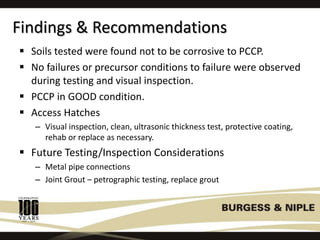

This document summarizes non-destructive testing methods used to evaluate prestressed concrete cylinder pipe (PCCP) for a water treatment plant in Ohio. Soil samples were taken and tested for resistivity, stray currents, chloride, sulfate, and pH levels. Visual inspections of exposed pipe joints showed the PCCP to be in good condition with loose grout. The soil was found to not be corrosive and no failures were observed. Access hatches showed surface corrosion and were recommended for further inspection and potential rehab. Future testing of metal connections and joint grout was also recommended.