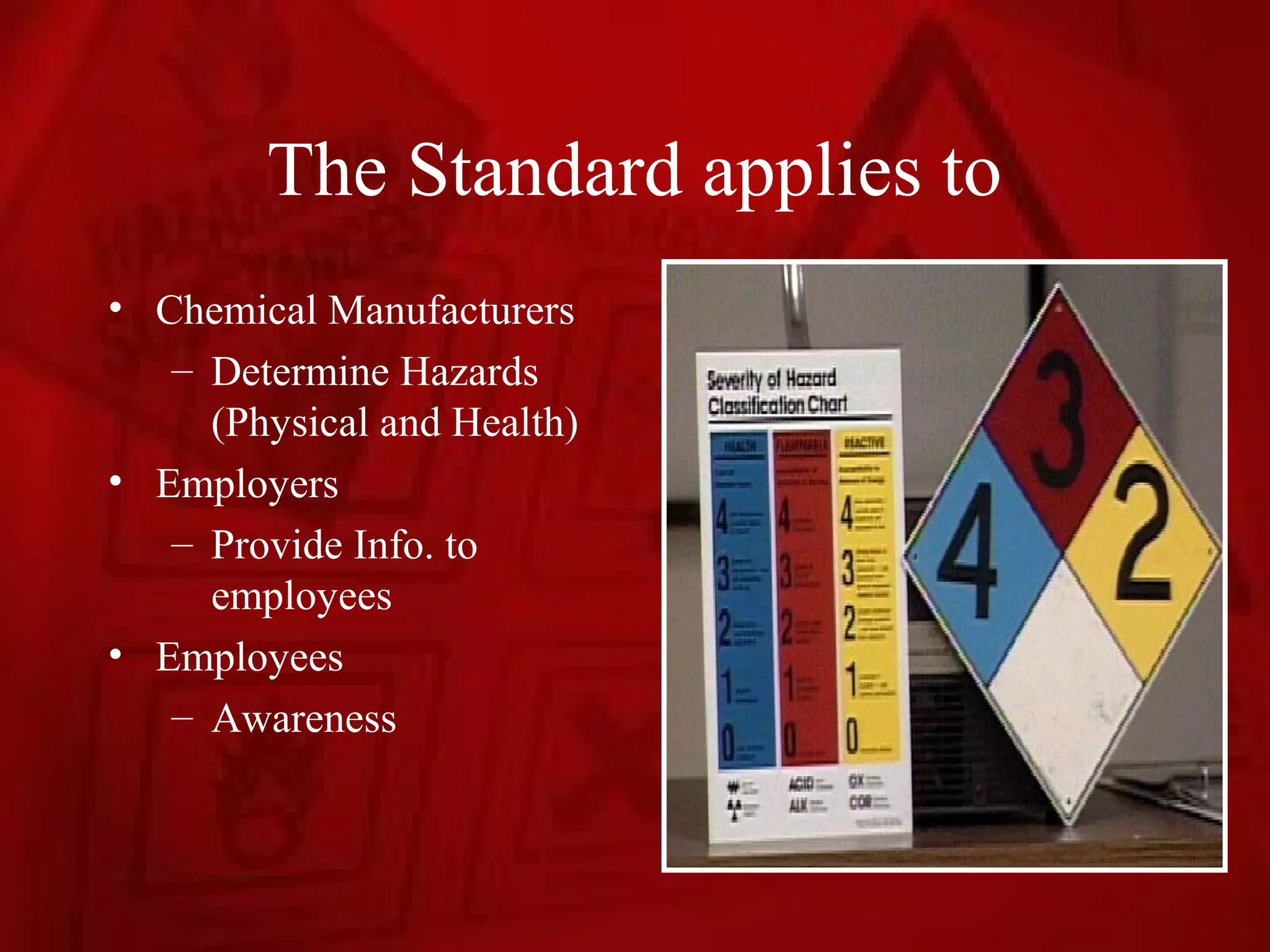

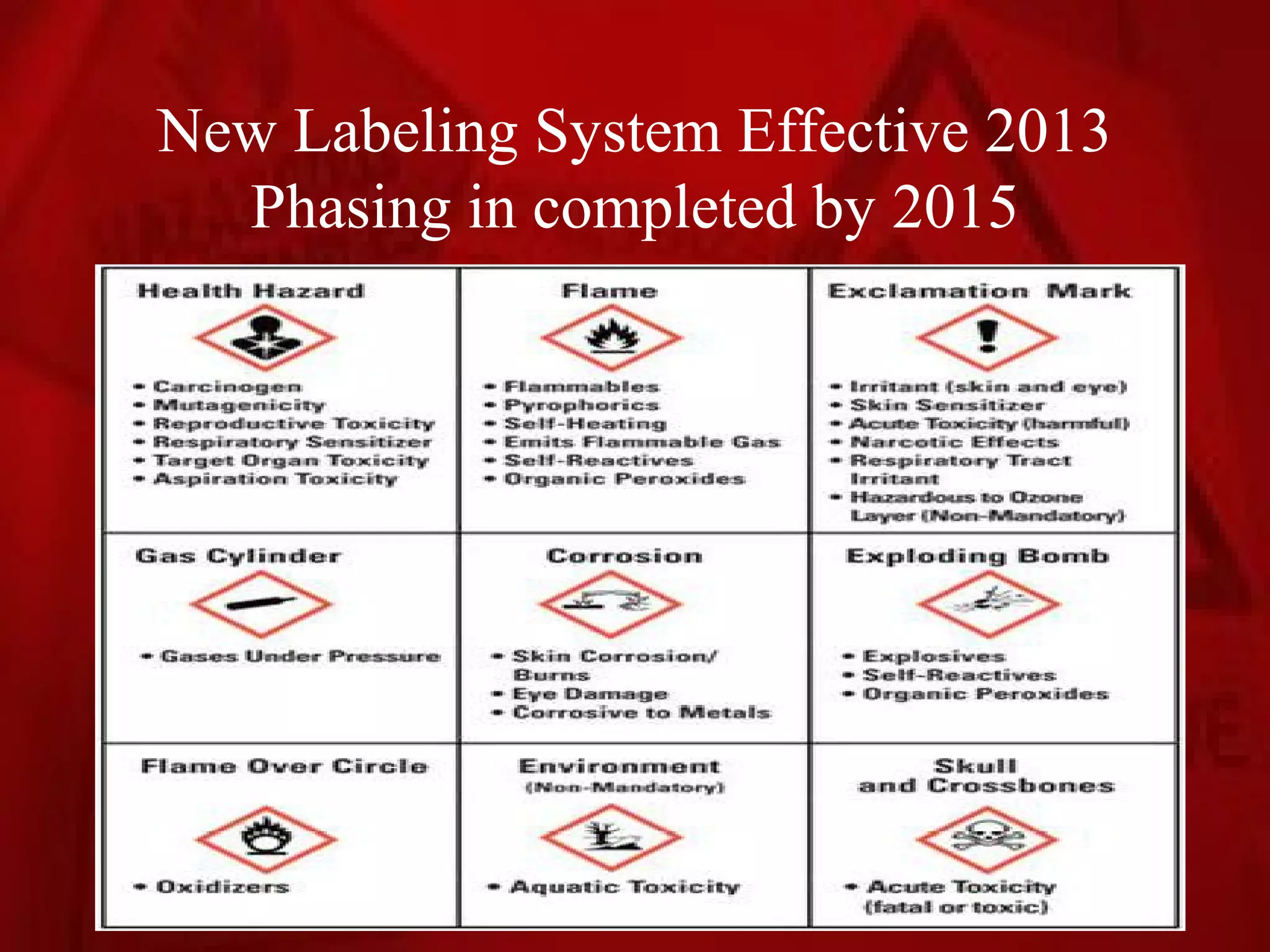

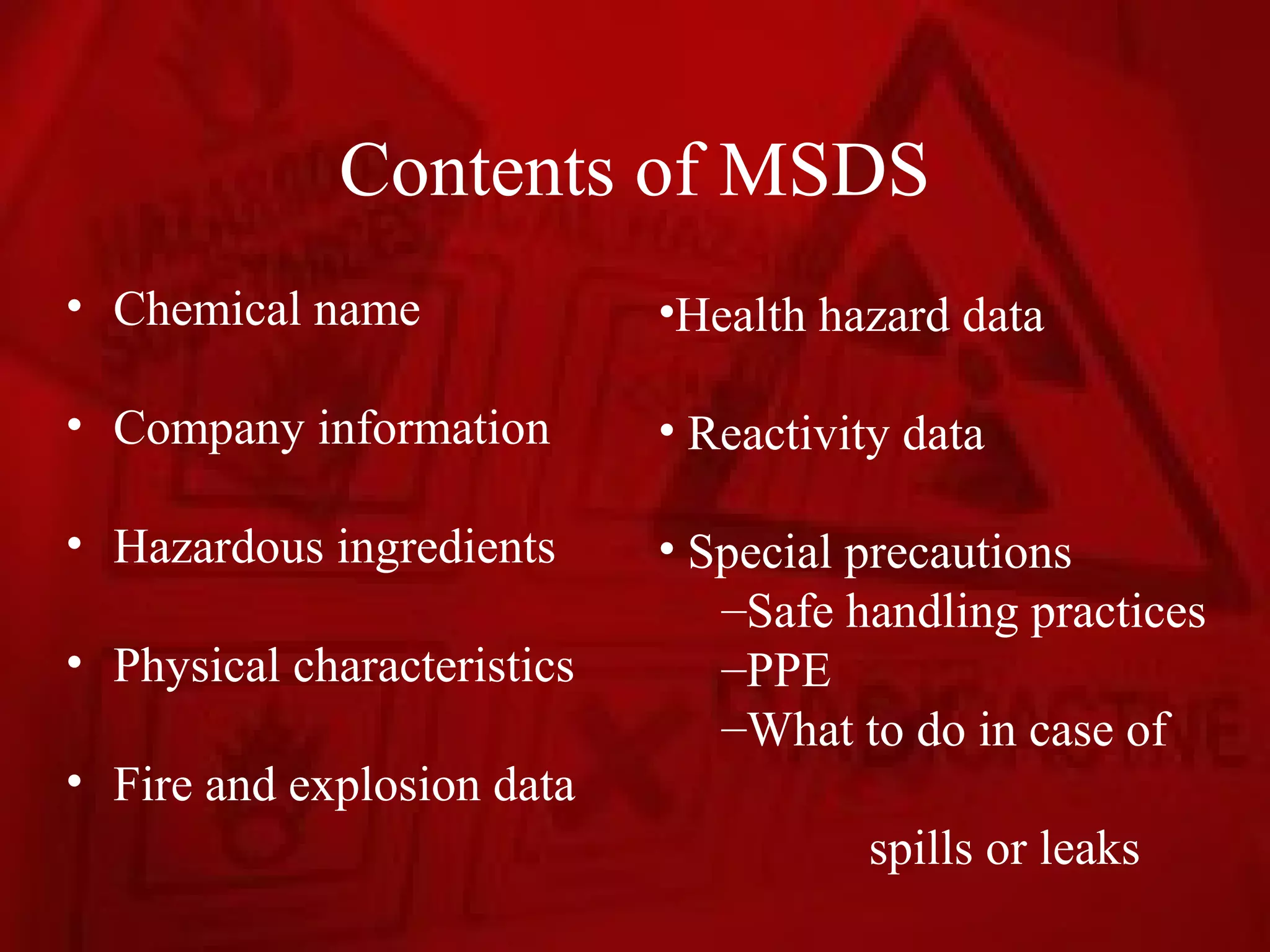

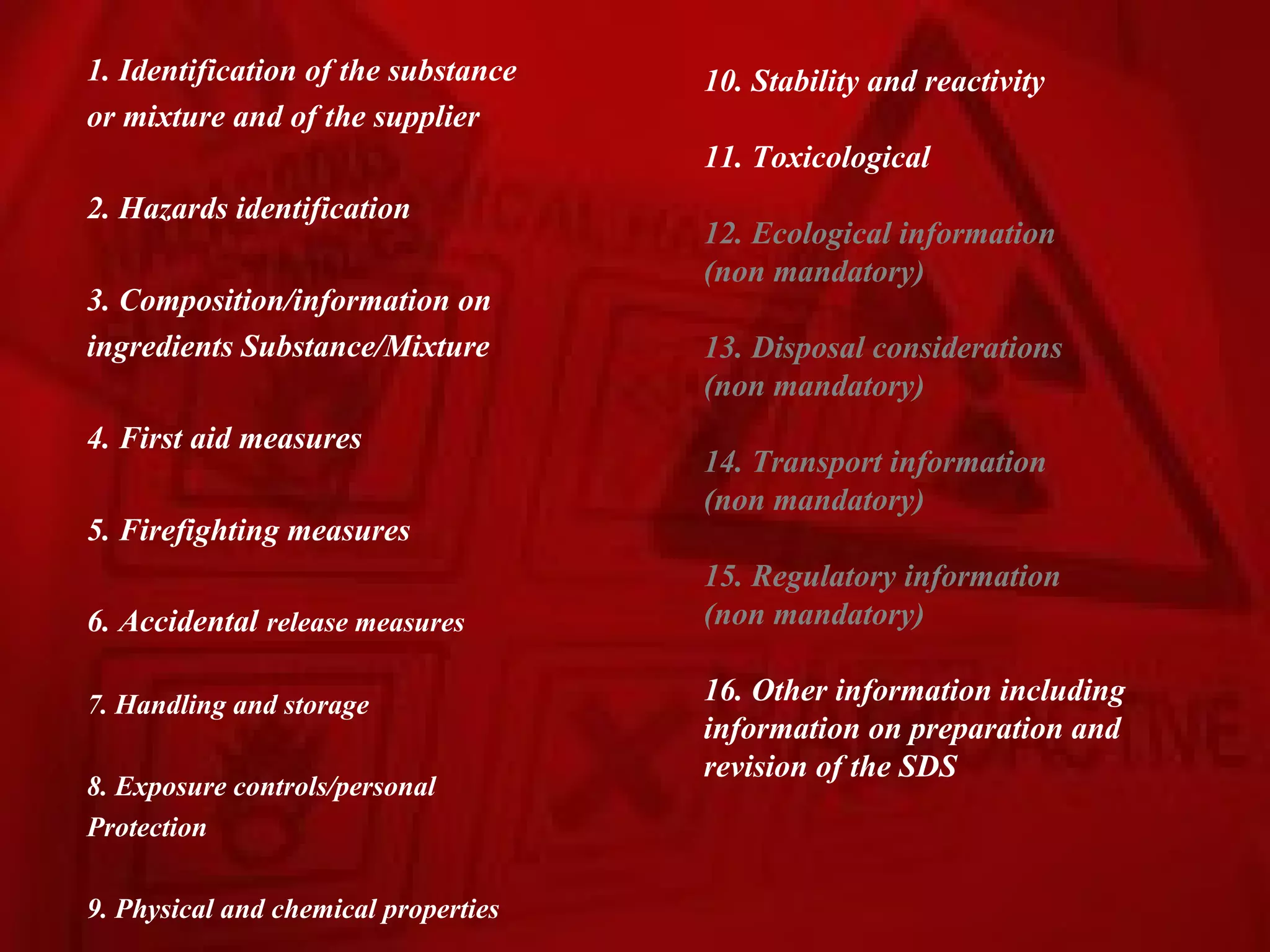

This document provides an annual refresher training on right-to-know, hazard communication, bloodborne pathogens, and exposure control. It reviews employees' right to know about chemical and biological hazards in the workplace. It discusses the hazard communication standard which requires labeling, material safety data sheets, and training programs. The training also covers bloodborne pathogens like HIV, HBV, and HCV; how exposure occurs; and required exposure control plans, universal precautions, personal protective equipment, decontamination, regulated medical waste, and proper incident response.