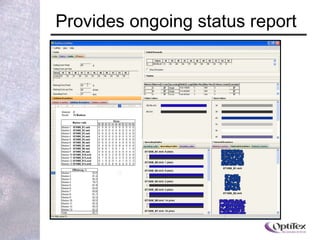

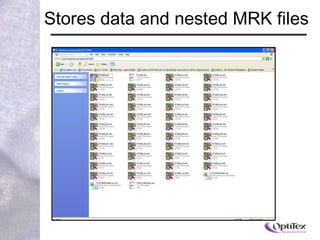

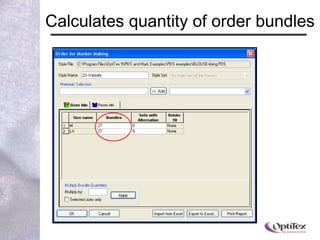

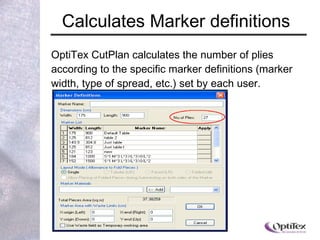

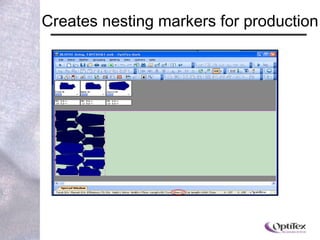

The document describes the OptiTex CutPlan solution which can help manufacturing plants improve efficiency and reduce costs by better managing the cutting process. It allows users to define fabrics and markers, receive accurate cost calculations and production status reports, store data in XML files, determine optimal nesting of markers to minimize waste and remnant pieces, and handle smaller order sizes. It aims to take control of costs and the cutting room by optimizing the number of plies and cuts while providing reports on marker definitions and production costs.