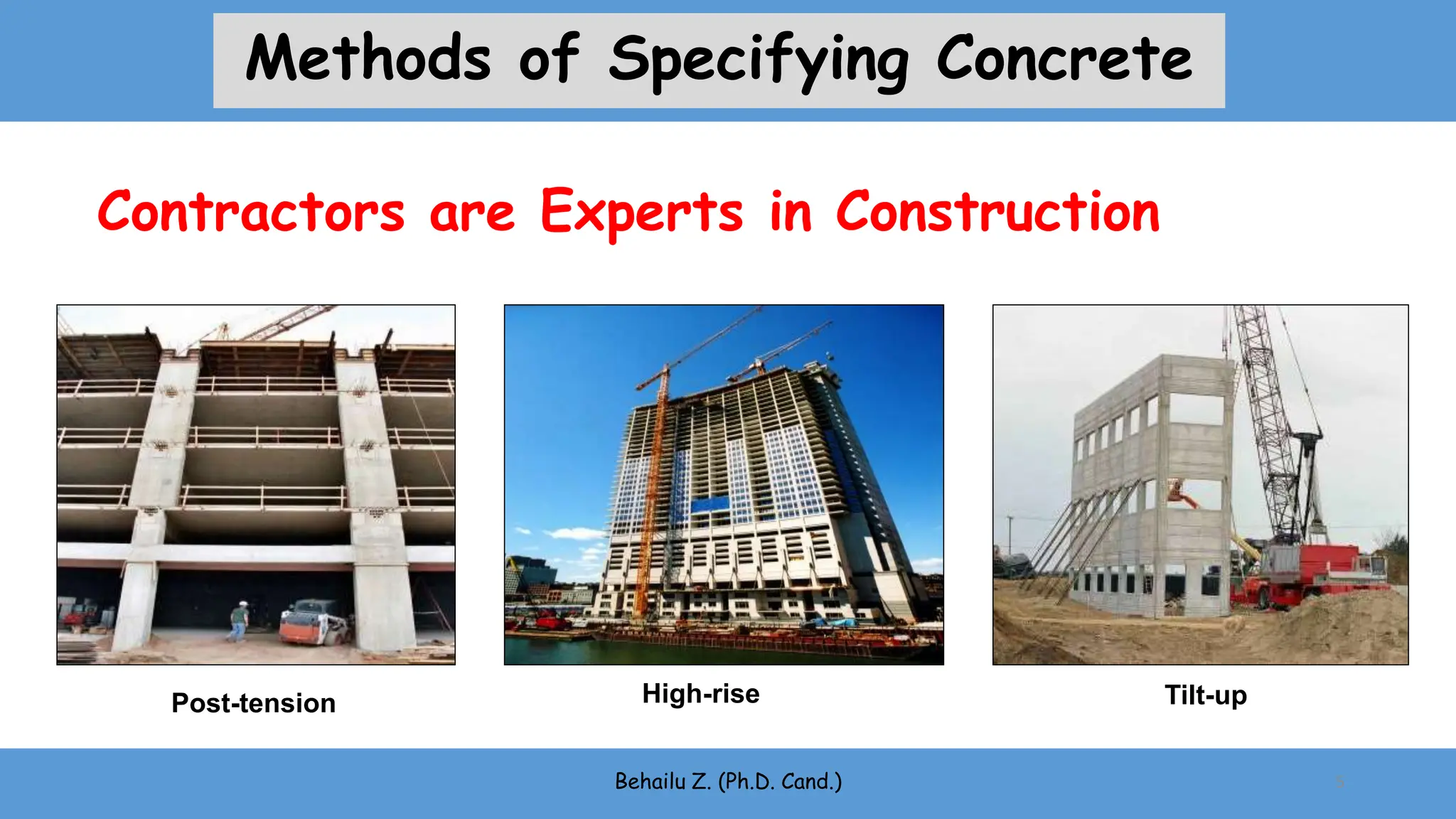

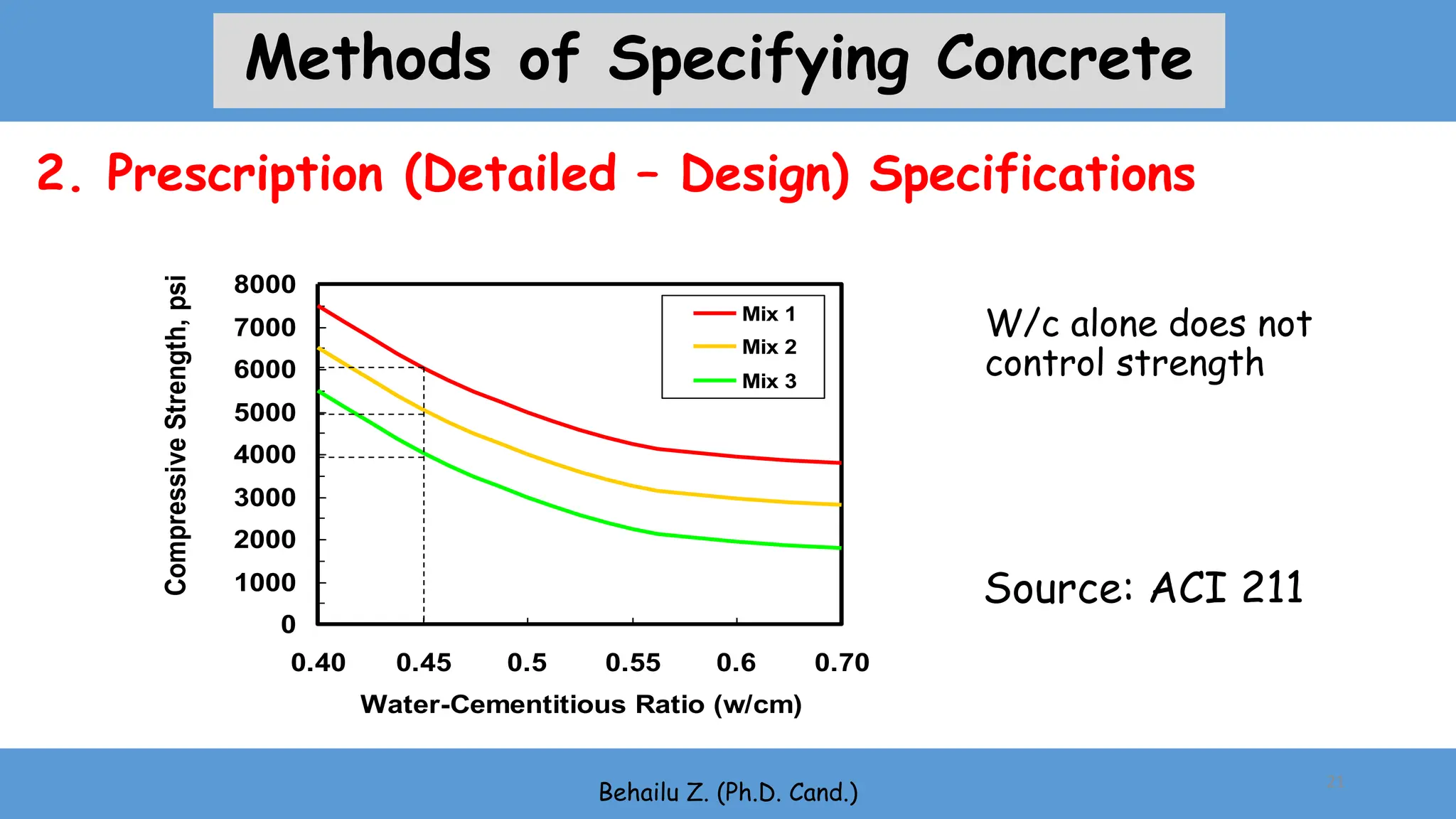

This document outlines the course contents for a Concrete Construction course. The course covers 5 topics: 1) Methods of Specifying Concrete, 2) Non Destructive Tests on Concrete, 3) Cold & Hot Weather Concreting, 4) High-performance Concrete, and 5) Special Types of Concrete. The first topic, Methods of Specifying Concrete, discusses the 4 main types of concrete specifications: performance-based, prescription-based, mixed, and proprietary specifications. It provides details on each type of specification and their advantages and disadvantages.