This document provides information about the ELEC-E5710 Sensors and Measurement Methods course, including:

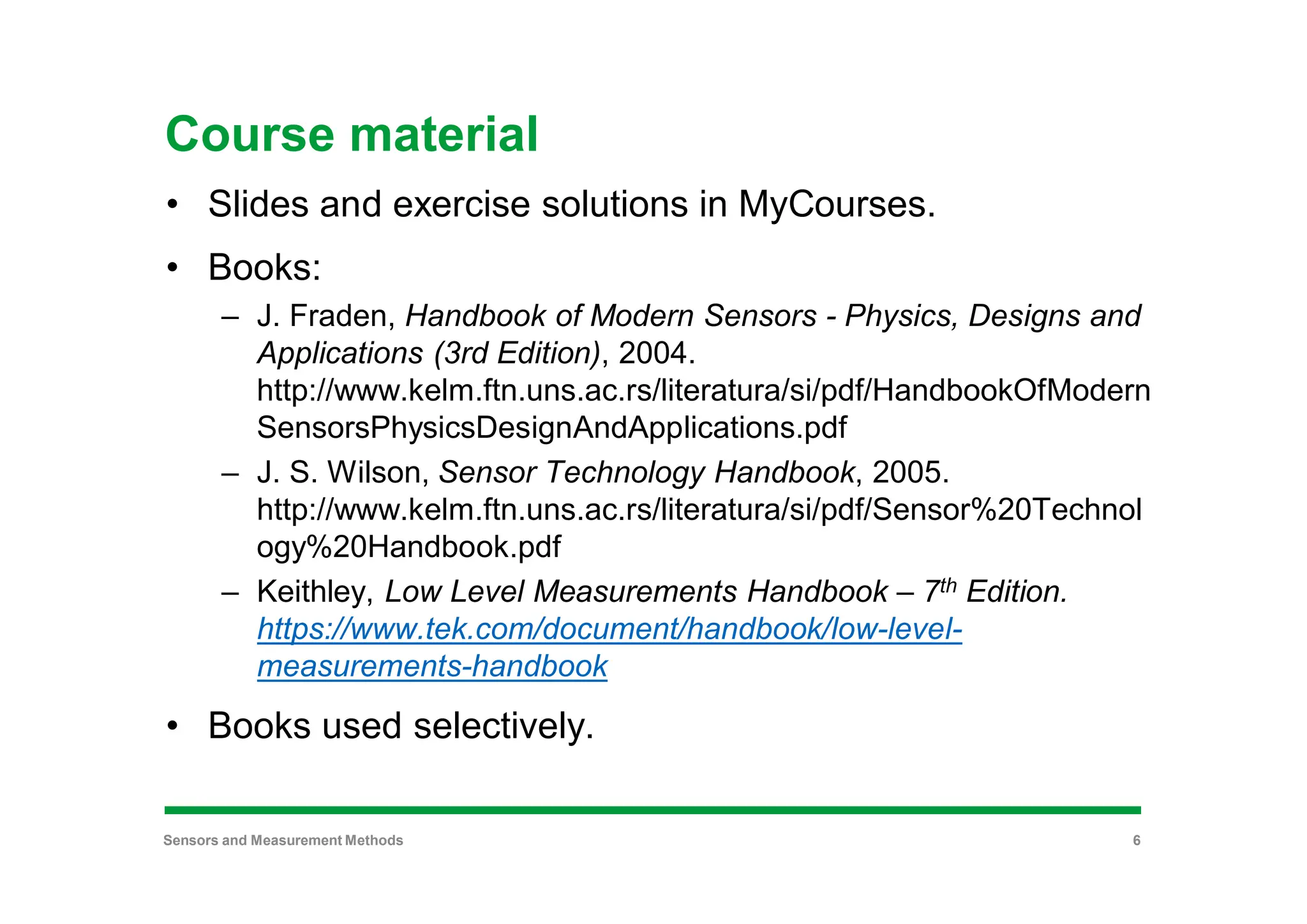

1) The course covers introduction to sensors, measurement systems, applicable sensors for measuring non-electrical quantities like temperature, light, mass and pressure.

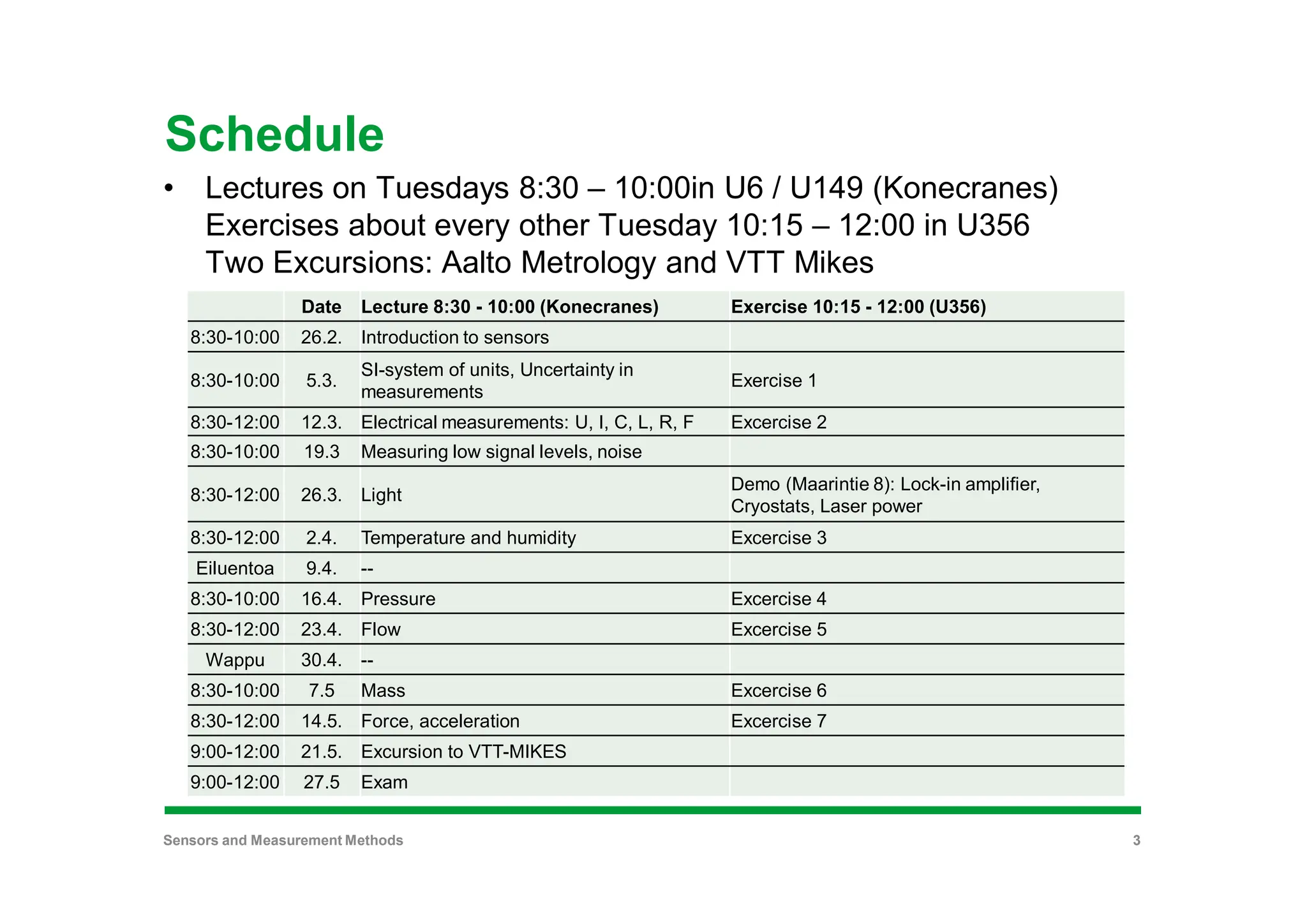

2) The schedule details the biweekly lectures and exercises, including two excursions to visit measurement facilities.

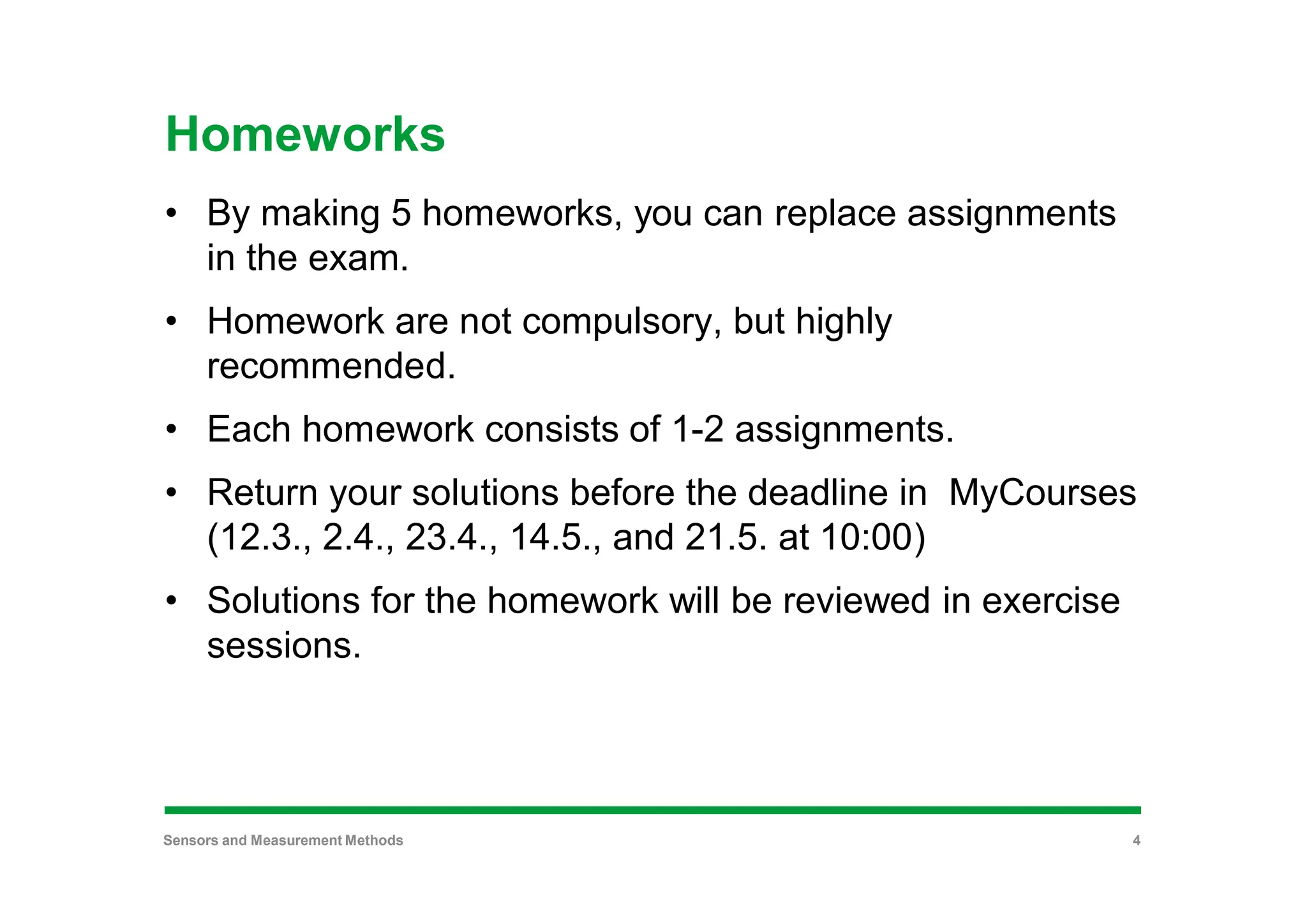

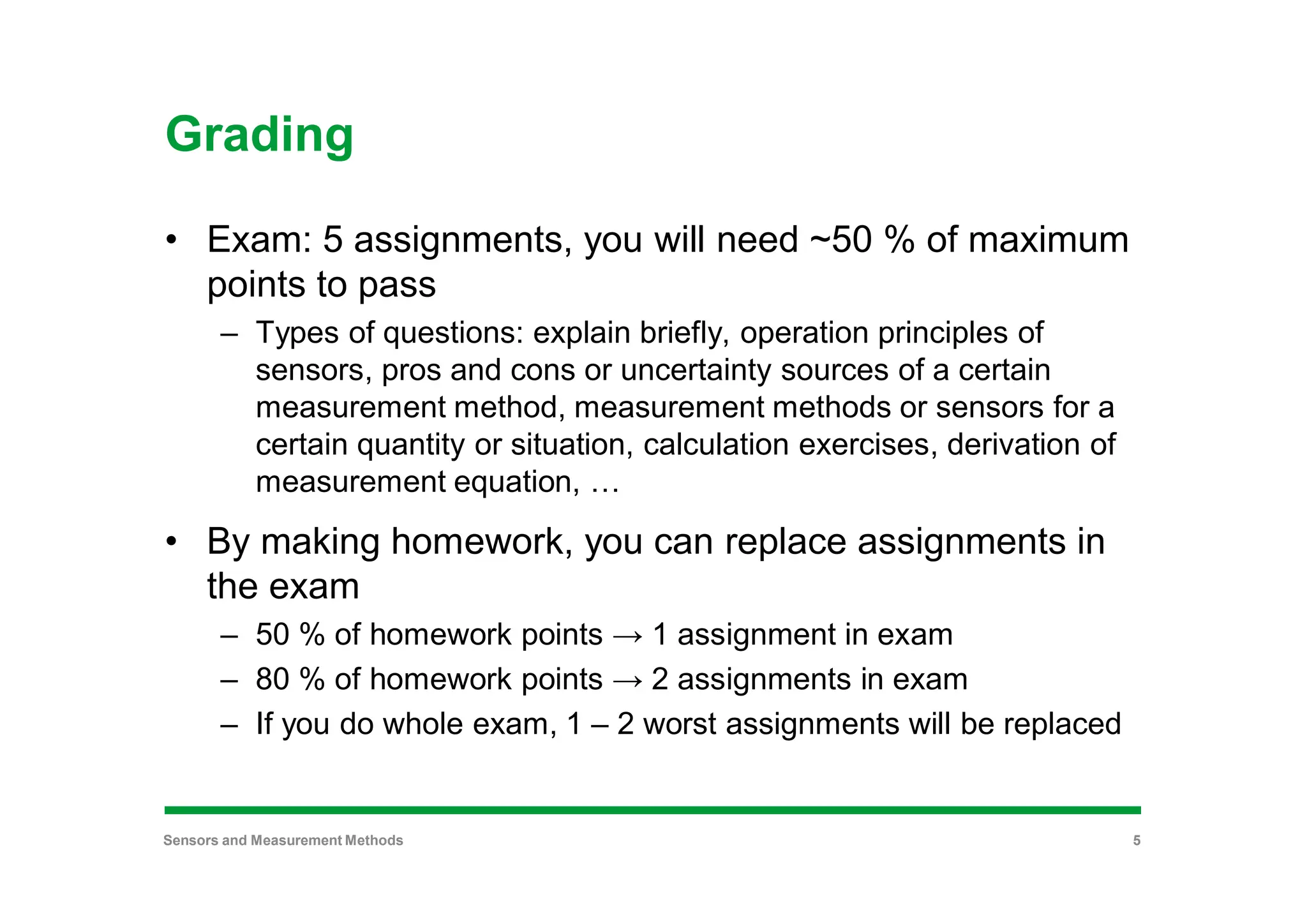

3) Students can improve their exam grade by completing optional homework assignments that replace exam questions.

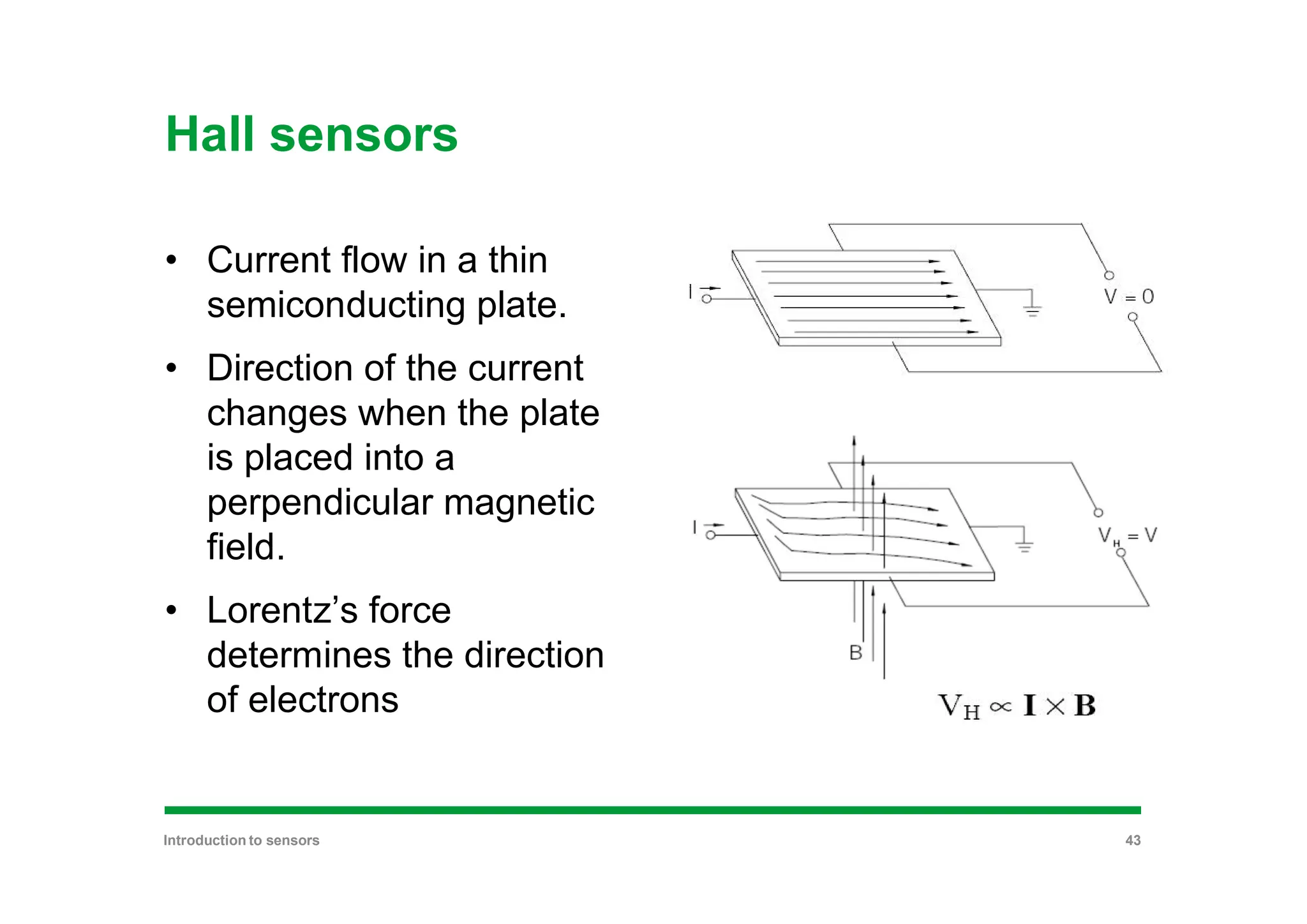

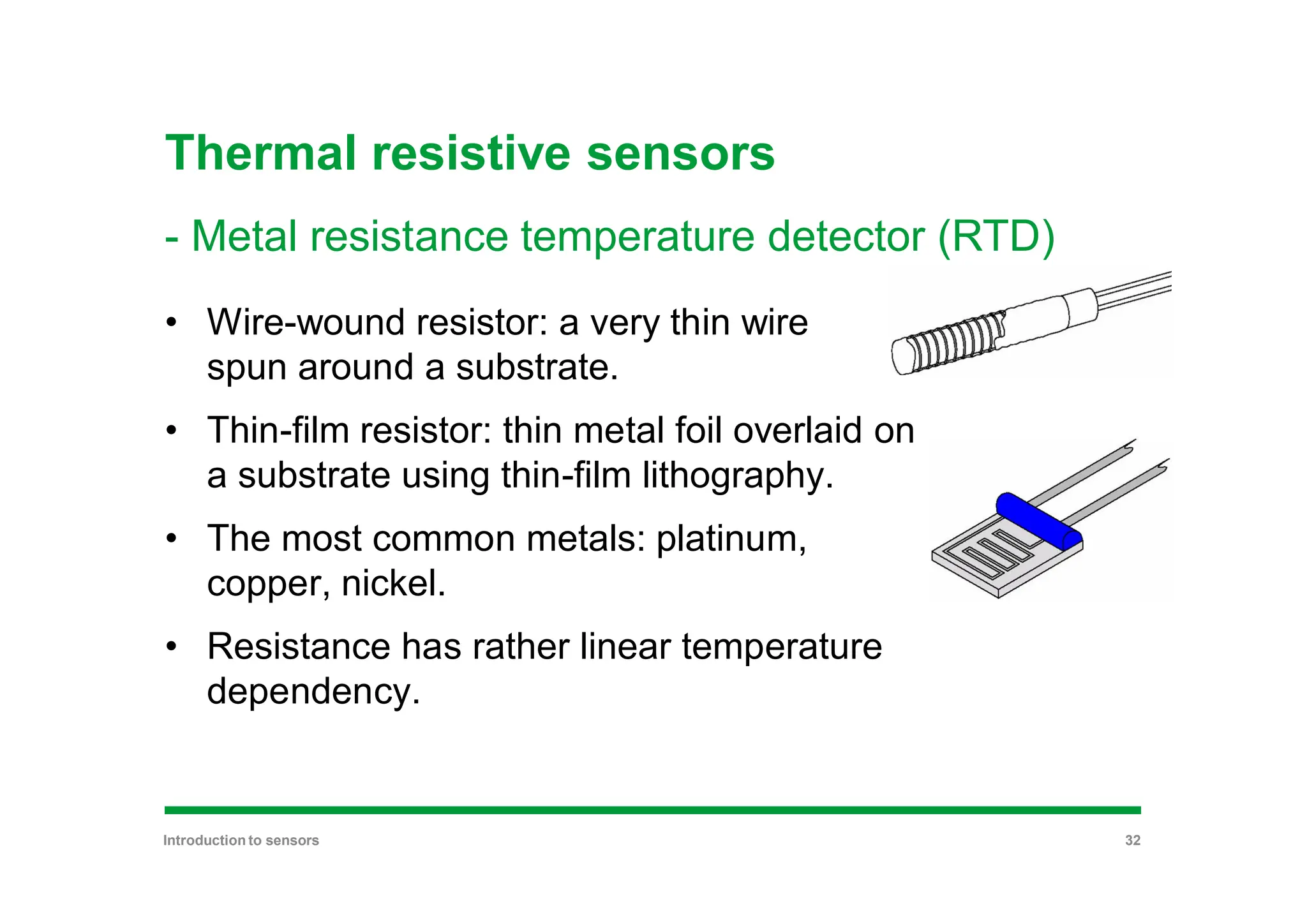

![Resistive sensors

• Resistance depends on resistivity r

[Wm] and geometry of a wire (cross-

sectional area A and length l):

• Resistivity depends on the electric field

strength E [V/m] and current density j

[A/m2]:

• Resistivity of metals depends

nearly linearly on temperature:

=

=

= [1 + − ]

Introduction to sensors 26](https://image.slidesharecdn.com/1-introduction2019-240120220917-bca3e97f/75/1-Introduction-to-power-electronics_2019-pdf-26-2048.jpg)

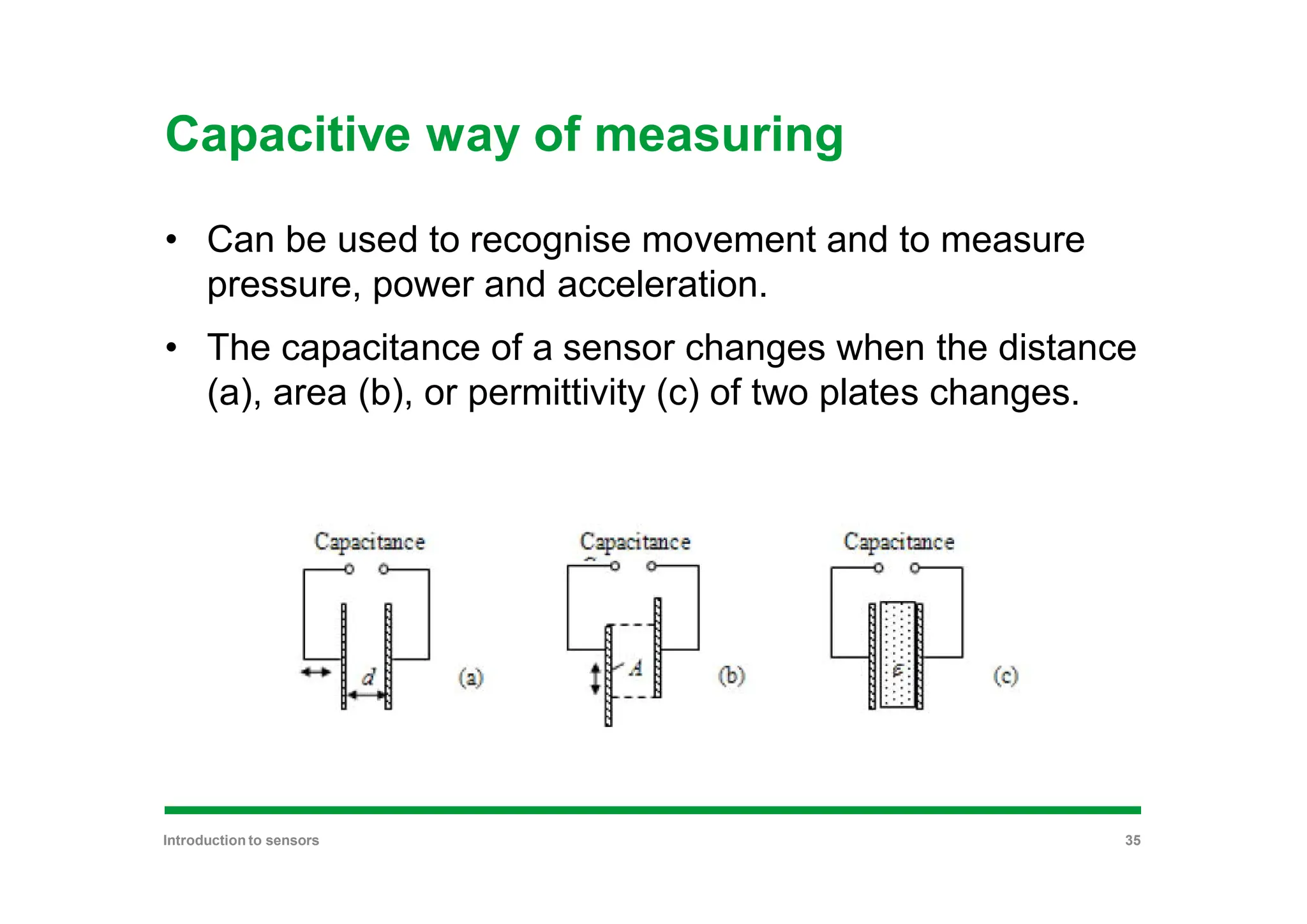

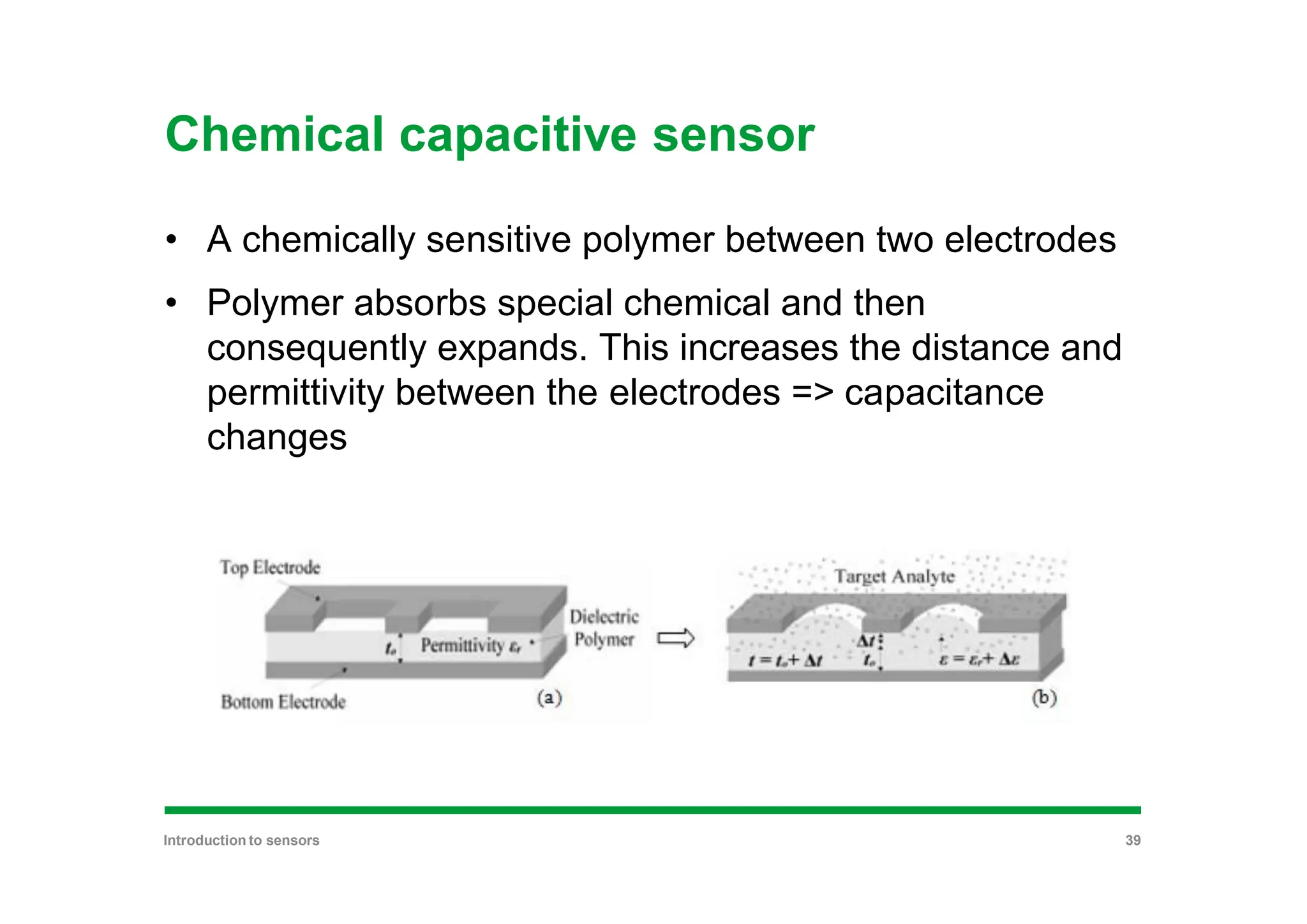

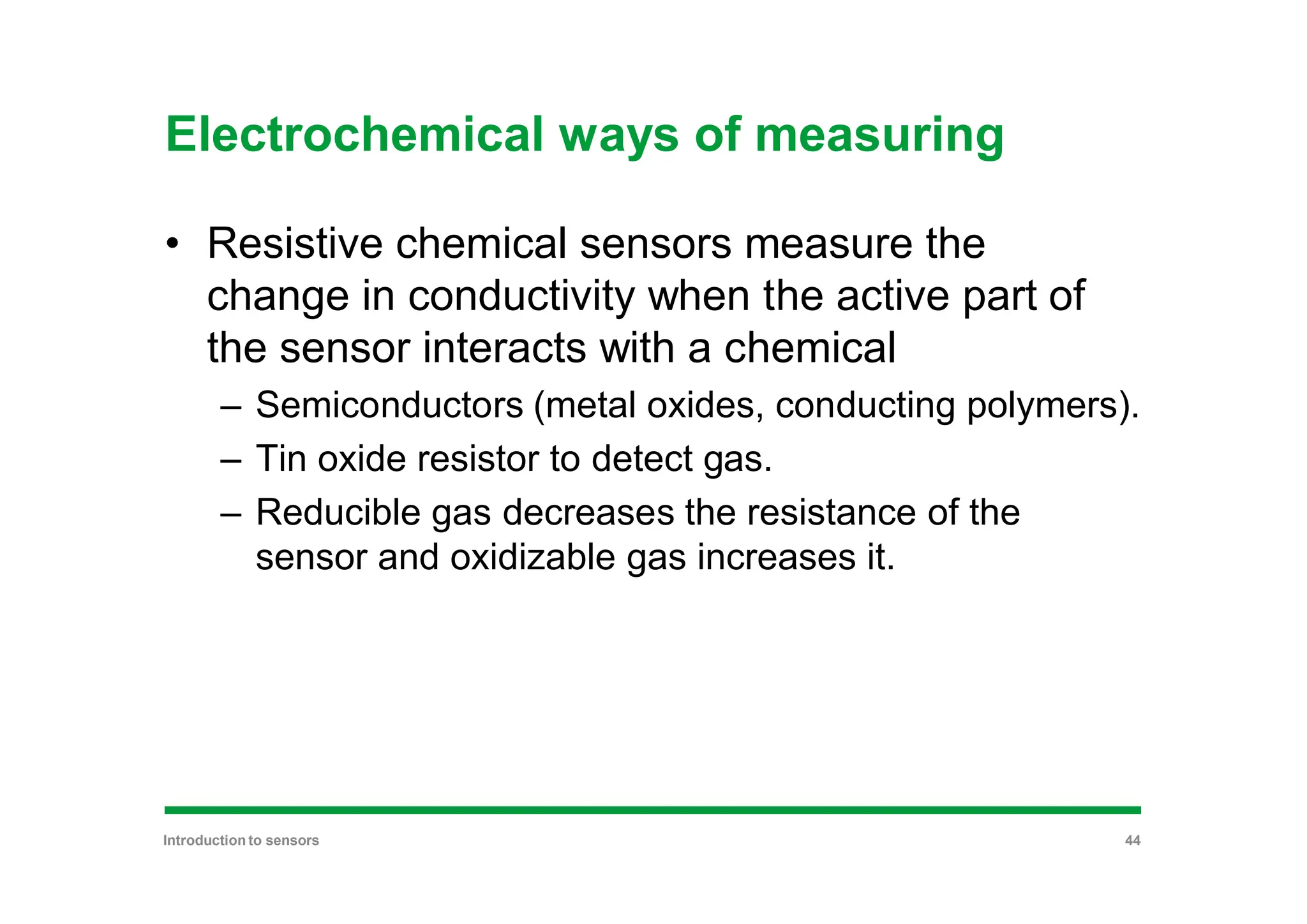

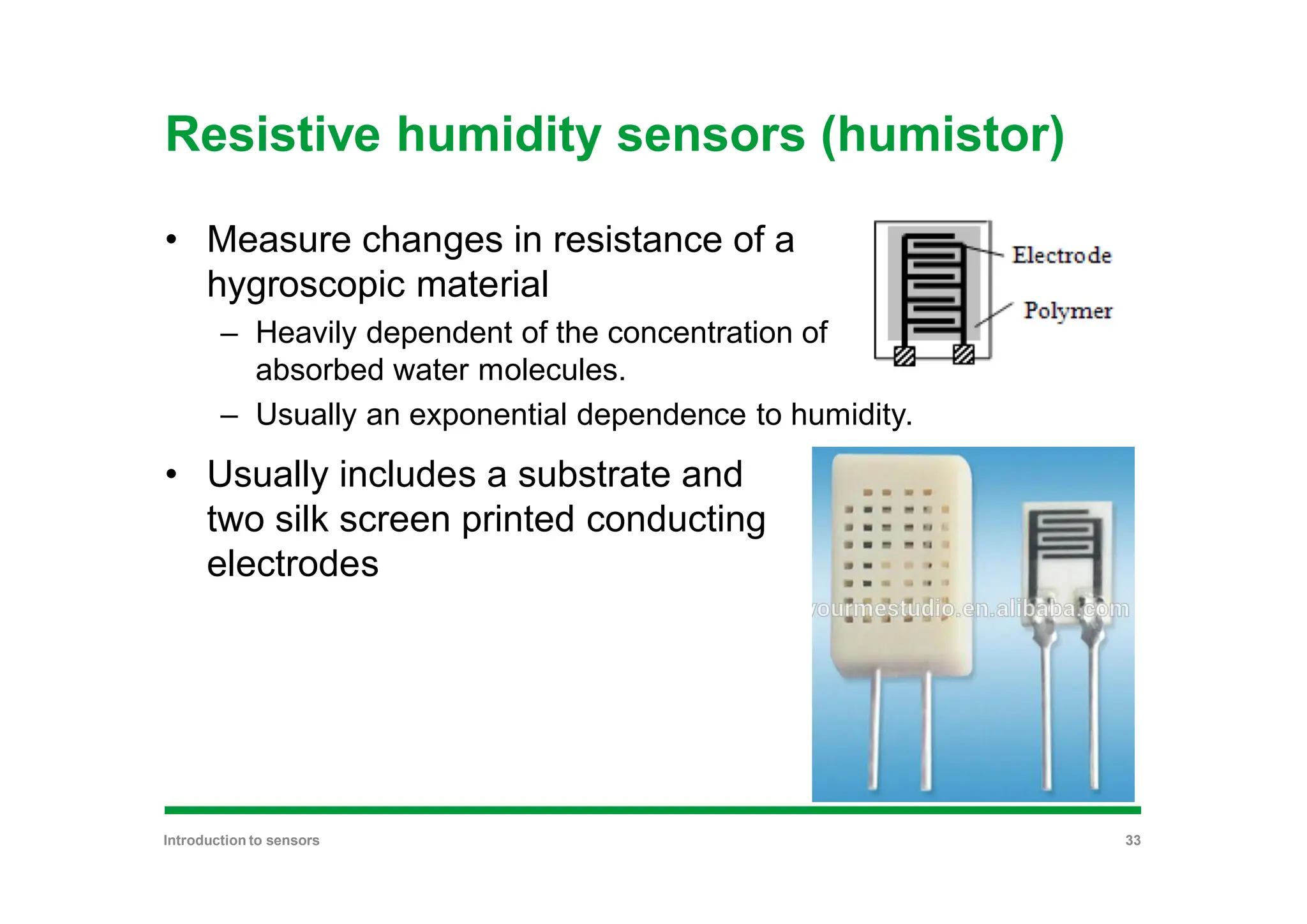

![Capacitive measurements

• Based on the change of capacitance when a specific

condition changes.

• Capacitance: =

– where is the relative static permittivity of the material, is

the electric constant, and G the geometry factor.

• G is dictated by the shape of the capacitor:

– Plate capacitor: = /

– Cylinder capacitor: = 2 /[ln ]

– Spherical capacitor: = 4 /( − )

Introduction to sensors 34](https://image.slidesharecdn.com/1-introduction2019-240120220917-bca3e97f/75/1-Introduction-to-power-electronics_2019-pdf-34-2048.jpg)