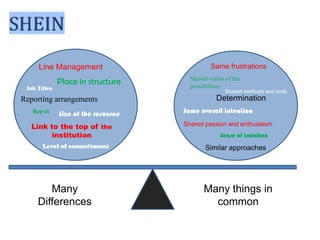

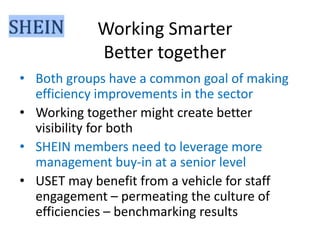

The document discusses the SHEIN initiative and its participation among various universities in Scotland. It highlights the shared goals of efficiency improvements, the need for senior management buy-in, and potential benefits for staff engagement. Additionally, it suggests developing training standards and institutional measures for successful improvement teams.