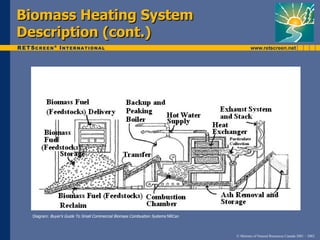

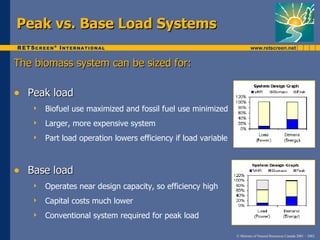

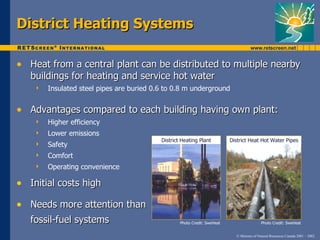

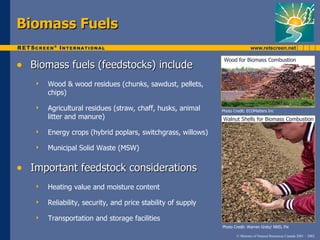

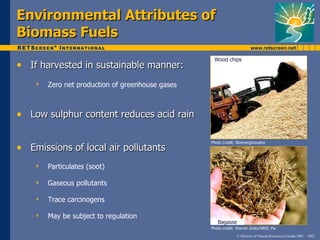

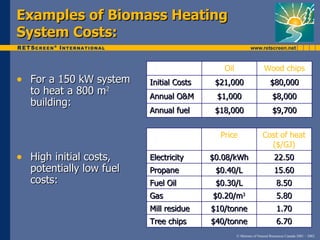

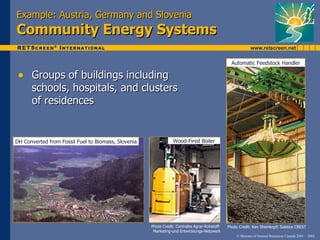

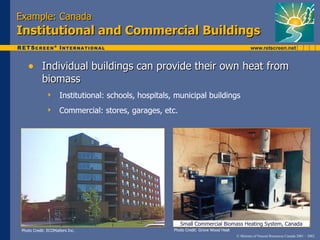

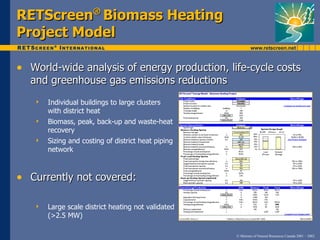

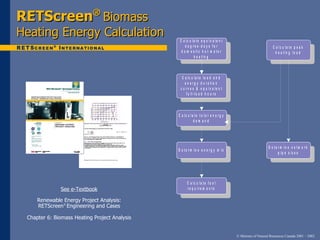

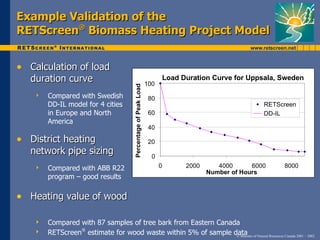

This document provides an overview of biomass heating systems and considerations for biomass heating project analysis. It discusses biomass heating system components, peak versus base load systems, district heating systems, biomass fuels, examples of system costs, project considerations, and the RETScreen biomass heating project model. The key information presented includes the components and operation of biomass heating systems, advantages of district heating systems, important biomass fuel characteristics and considerations, and a tool for analyzing the energy production, costs and emissions of biomass heating projects.