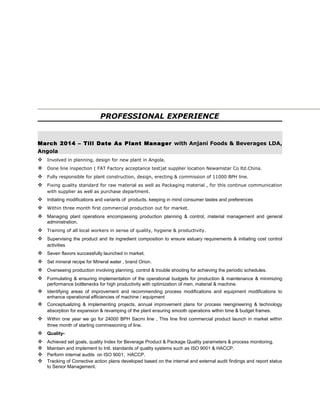

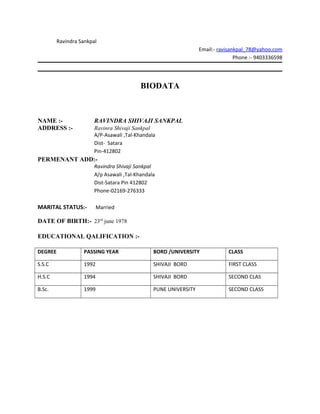

Ravindra Sankpal is seeking managerial roles in quality management and process enhancement, preferably in the food and beverage industry. He has over 17 years of experience in quality management and has worked as a plant manager. He is skilled in quality systems, production, new product launches, and improving operations. Some of his achievements include increasing production capacity by 300%, implementing HACCP, and helping a facility become one of Angola's largest beverage manufacturers.